At its core, freeze-drying is a preservation technology that excels at locking in quality and extending stability. It significantly extends the shelf life of products, preserves their nutritional and chemical integrity, and maintains their original structure, color, and flavor. This unique combination of benefits makes it an invaluable process across diverse industries, from pharmaceuticals and biotechnology to high-end food and cannabis production.

Unlike conventional heat-based drying which degrades products, freeze-drying removes water through a gentle, low-temperature process called sublimation. This mechanism is the fundamental reason it can preserve the delicate structure and chemical composition of everything from a strawberry to a life-saving vaccine.

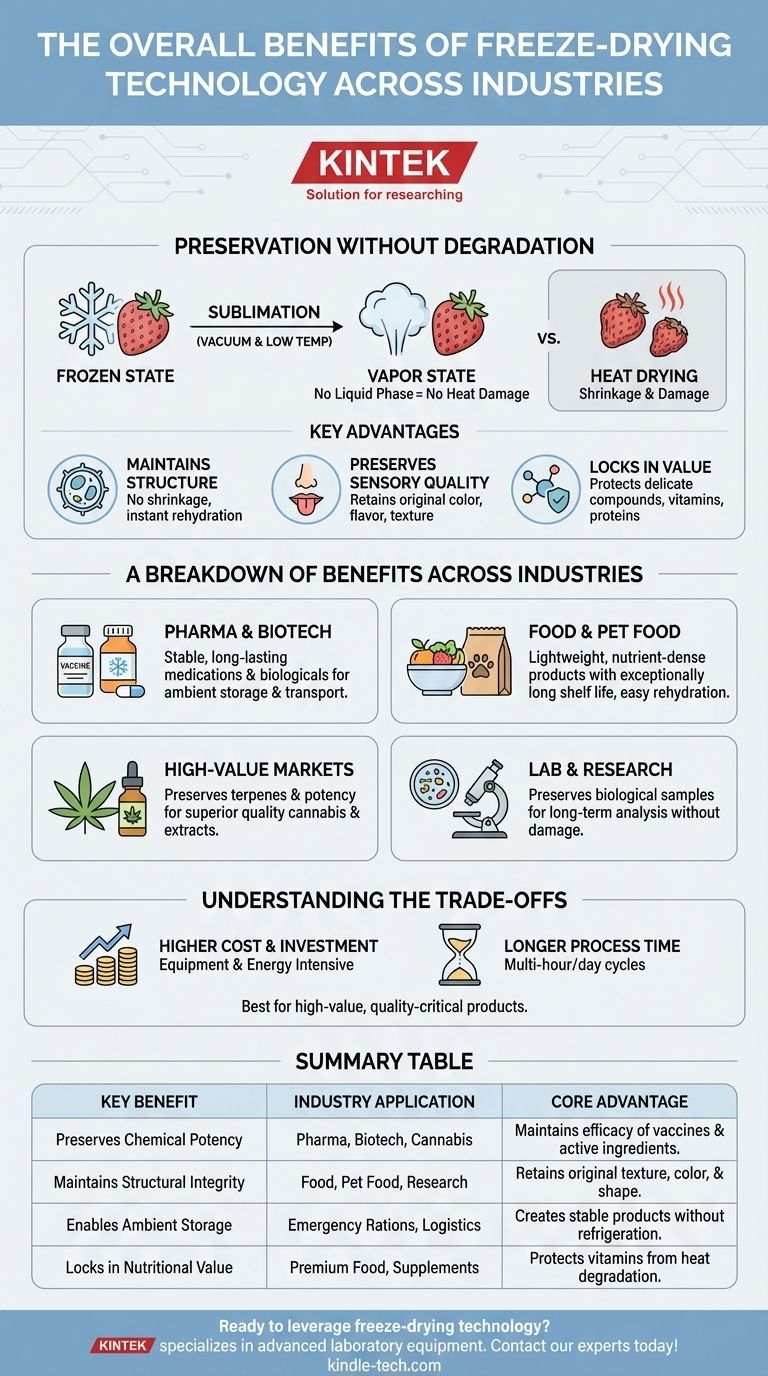

The Foundational Advantage: Preservation Without Degradation

The true power of freeze-drying, or lyophilization, lies in how it removes water. By avoiding the damaging effects of heat, it preserves materials in a state remarkably close to their original form.

How Sublimation Protects Product Integrity

Most drying methods use heat to evaporate water from a liquid to a gas. This process can shrink and damage the cellular structure of the material, destroying delicate compounds.

Freeze-drying bypasses the liquid phase entirely. The product is first frozen, and then a deep vacuum is applied, causing the frozen water to turn directly into vapor—a process called sublimation. This gentle transition leaves the product's structure intact.

Maintaining Structural and Sensory Qualities

Because the water is removed without passing through a liquid state, the product's physical structure is not compromised. Conventional drying causes shrinkage and toughness as water is drawn out, altering the final texture.

Freeze-drying, in contrast, maintains the original size and shape, creating a porous structure that rehydrates instantly. This is why freeze-dried foods retain their original texture, color, and taste far more effectively than their dehydrated counterparts.

Locking in Nutritional and Chemical Value

Heat is the enemy of many sensitive biological and chemical compounds. The low-temperature nature of freeze-drying is critical for preserving the potency of active ingredients.

This applies to the vitamins in food, the terpenes and cannabinoids in cannabis, and the complex proteins and antibodies in biopharmaceuticals. The process ensures the final product is not just preserved, but remains effective and valuable.

A Breakdown of Benefits Across Key Industries

The versatility of freeze-drying has made it a cornerstone technology in multiple sectors where quality and stability are non-negotiable.

For Pharmaceuticals and Biotechnology

Freeze-drying is essential for creating stable, long-lasting medications and biologicals. It allows for the production of vaccines, proteins, antibodies, and other sensitive drugs that can be stored and transported without refrigeration. This vastly improves logistical efficiency and access to life-saving treatments.

For the Food and Pet Food Industry

This technology produces lightweight, nutrient-dense foods with an exceptionally long shelf life, requiring no chemical preservatives or refrigeration. Products from instant coffee and military rations to premium pet food are easy to store, cheap to transport, and can be quickly reconstituted by simply adding water.

For Emerging High-Value Markets

Industries like the legal cannabis market have adopted freeze-drying to produce superior products. Traditional curing methods can degrade delicate aroma compounds (terpenes) and reduce potency. Freeze-drying preserves these qualities, resulting in a higher-quality, safer, and more valuable final product.

For Laboratory and Research Settings

In bioengineering, material science, and other research fields, freeze-drying is used to preserve biological samples for long-term analysis. It provides scientists with a way to stop biological activity without damaging the sample, allowing for accurate study at a later date.

Understanding the Trade-offs

While its benefits are significant, freeze-drying is not a universal solution. Understanding its limitations is key to making an informed decision.

The Cost of Quality

Freeze-drying equipment represents a significant capital investment. The process itself is also more energy-intensive and expensive per unit compared to simple air or heat drying, making it less economical for low-value products.

The Time Factor

The freeze-drying cycle—from freezing to primary drying (sublimation) to secondary drying—is a slow, multi-hour or even multi-day process. This low throughput can be a limiting factor for high-volume production lines.

Not a Universal Solution

The combination of high cost and long processing times means freeze-drying is typically reserved for products where the preservation of quality, potency, or specific structural characteristics justifies the expense. For simple bulk commodities, cheaper drying methods are often sufficient.

Making the Right Choice for Your Goal

The decision to use freeze-drying technology should be driven by the specific requirements of your product and business.

- If your primary focus is preserving maximum chemical potency and sensory quality: Freeze-drying is the definitive choice for high-value pharmaceuticals, biotech materials, premium cannabis, and gourmet foods.

- If your primary focus is long-term, unrefrigerated shelf life and reduced logistics costs: The technology is ideal for creating stable food supplies, emergency rations, and easier-to-transport biologicals.

- If your primary focus is low-cost, high-volume production of a durable good: Conventional drying methods are likely more cost-effective, as the benefits of freeze-drying may not outweigh its expense and time commitment.

Ultimately, freeze-drying is an investment in unparalleled preservation, chosen when the integrity of the final product cannot be compromised.

Summary Table:

| Key Benefit | Industry Application | Core Advantage |

|---|---|---|

| Preserves Chemical Potency | Pharmaceuticals, Biotechnology, Cannabis | Maintains efficacy of vaccines, proteins, and cannabinoids |

| Maintains Structural Integrity | Food, Pet Food, Research | Retains original texture, color, and shape for easy rehydration |

| Enables Ambient Storage | Emergency Rations, Logistics | Creates stable products without refrigeration |

| Locks in Nutritional Value | Premium Food, Supplements | Protects vitamins and sensitive compounds from heat degradation |

Ready to leverage freeze-drying technology for your high-value products? KINTEK specializes in providing advanced laboratory equipment and consumables to meet the precise demands of industries like pharmaceuticals, biotechnology, and premium food production. Our expertise ensures you get the right solutions to preserve product integrity, extend shelf life, and enhance market value. Contact our experts today to discuss how we can support your preservation goals!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What role does a laboratory freeze dryer play in the synthesis of graphene-based electrocatalysts? Preserve 3D Structures

- Why is a freeze dryer preferred for drying nickel nanoparticle precursors? Prevent Hard Agglomeration Now

- What is the purpose of an evaporator? The Key Component That Creates Cooling

- What are the advantages of using freeze drying for phase change materials with biopolymer shells? Optimize Stability

- Why is a freeze dryer preferred for reduced graphene oxide (Hh-RGO) powders? Preserve Nano-Structure and Performance