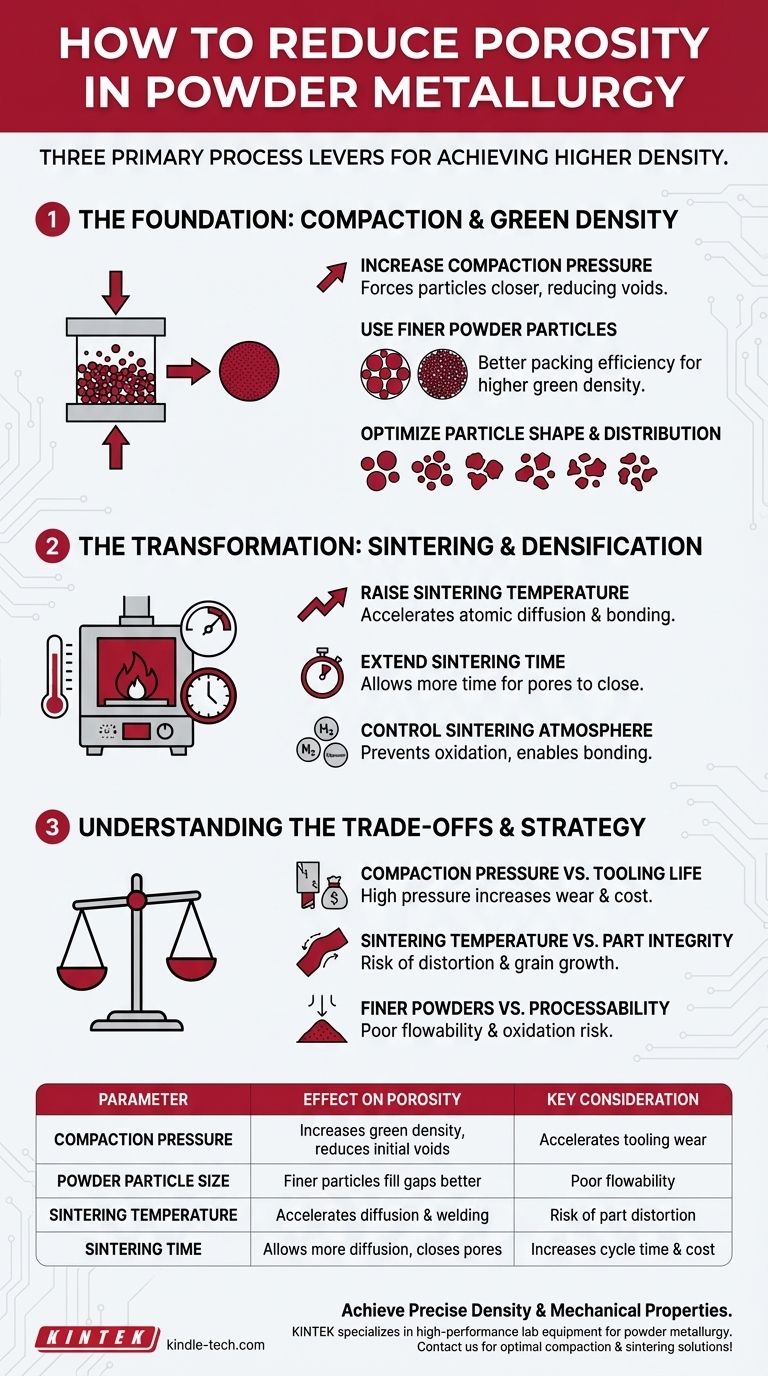

To reduce porosity in powder metallurgy, you must focus on three primary process levers: increasing the compaction pressure, raising the sintering temperature while extending the sintering time, and using finer powder particles. These adjustments work together to minimize the void space between powder particles both before and during the heat treatment process, leading to a denser final part.

Porosity is an inherent characteristic of powder metallurgy, but controlling it is the key to achieving the desired mechanical properties. The goal is to maximize particle-to-particle contact and atomic diffusion, which transforms a loosely packed powder compact into a dense, solid-like material.

The Foundation: Compaction and Green Density

The first opportunity to reduce porosity occurs during the initial pressing of the powder into a "green" compact, before any heat is applied. The density at this stage is known as green density.

The Role of Compaction Pressure

Increasing the pressure applied during compaction forces the powder particles closer together. This mechanical force deforms the particles, reducing the interstitial voids and creating a more densely packed structure from the start.

The Influence of Particle Size

Using finer powder particles is a critical strategy for reducing initial porosity. Smaller particles can more effectively fill the gaps between larger ones, leading to a higher packing efficiency and a higher green density, much like how sand can fill the voids between large rocks in a jar.

Particle Shape and Distribution

While finer particles are key, their shape and distribution also matter. A mix of different particle sizes (a broad distribution) often packs more efficiently than a collection of uniformly sized particles. Irregularly shaped particles may interlock better under pressure, though spherical powders tend to flow more easily into the die.

The Transformation: Sintering and Densification

Sintering is the thermal process where the green compact is heated to below its melting point. This is where the most significant porosity reduction and bonding occur.

The Effect of Sintering Temperature

Higher sintering temperatures provide more thermal energy, which dramatically accelerates atomic diffusion. Atoms move across the boundaries of adjacent particles, effectively "welding" them together. This process fills in the pores and causes the entire part to shrink and densify.

The Importance of Sintering Time

Diffusion is a time-dependent process. Extending the sintering time allows the atomic transport mechanism more time to work, closing off more pores and further increasing the part's final density.

The Sintering Atmosphere

The atmosphere inside the furnace (e.g., hydrogen, nitrogen, or a vacuum) is crucial. A controlled atmosphere prevents oxidation of the powder surfaces, which would otherwise inhibit the atomic bonding required for densification.

Understanding the Trade-offs

While these methods are effective, they are not without limitations. Pushing any single parameter to its extreme can introduce new problems.

Compaction Pressure vs. Tooling Life

Extremely high compaction pressures significantly increase the stress on the dies and punches. This leads to accelerated tooling wear and a higher risk of failure, increasing operational costs. It can also introduce internal stresses in the green compact.

Sintering Temperature vs. Part Integrity

Sintering too close to the material's melting point can cause part distortion, slumping, or undesirable grain growth. Large grains can actually make the final material more brittle, counteracting the benefits of higher density.

Finer Powders vs. Processability

Very fine powders, while good for density, can exhibit poor flowability. This makes it difficult to achieve a uniform and consistent fill of the die cavity, which can lead to density variations and defects in the final part. They are also more susceptible to oxidation due to their high surface area.

Making the Right Choice for Your Goal

Your strategy for reducing porosity should be guided by the specific performance requirements and economic constraints of your project.

- If your primary focus is maximum density and strength: Combine high compaction pressures with a high-temperature, long-duration sintering cycle, and consider secondary operations like Hot Isostatic Pressing (HIP).

- If your primary focus is cost-efficiency for standard parts: Use moderate compaction pressures and optimized sintering profiles with standard-grade powders to balance performance with tooling life and energy costs.

- If your primary focus is high dimensional accuracy: Avoid excessively high sintering temperatures that could lead to distortion and carefully control the powder fill process to ensure uniform shrinkage.

By strategically balancing these process parameters, you can engineer the precise level of density required for your application's success.

Summary Table:

| Parameter | Effect on Porosity | Key Consideration |

|---|---|---|

| Compaction Pressure | Increases green density, reduces initial voids | High pressure accelerates tooling wear |

| Powder Particle Size | Finer particles fill gaps better, improving packing | Very fine powders have poor flowability |

| Sintering Temperature | Higher temps accelerate atomic diffusion, welding particles | Risk of part distortion or grain growth |

| Sintering Time | Longer times allow more diffusion, closing pores | Increases process cycle time and cost |

Achieve the precise density and mechanical properties your application demands.

The strategies outlined are a starting point, but successfully implementing them requires expert knowledge and reliable equipment. KINTEK specializes in high-performance lab equipment and consumables for powder metallurgy, serving laboratories and R&D departments with the tools needed for optimal compaction and sintering processes.

Let our experts help you select the right equipment and optimize your parameters to minimize porosity and maximize part strength. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

People Also Ask

- What is cold isostatic pressing mold material? Essential Elastomers for Uniform Density

- How big is the isostatic pressing market? A Deep Dive into the $1.2B+ Advanced Manufacturing Enabler

- What is cold isostatic pressing examples? Achieve Uniform Density in Powder Compaction

- What is the process of isostatic graphite? A Guide to High-Performance, Uniform Material Creation

- What are the applications of cold isostatic pressing? Achieve Uniform Density for Complex Parts