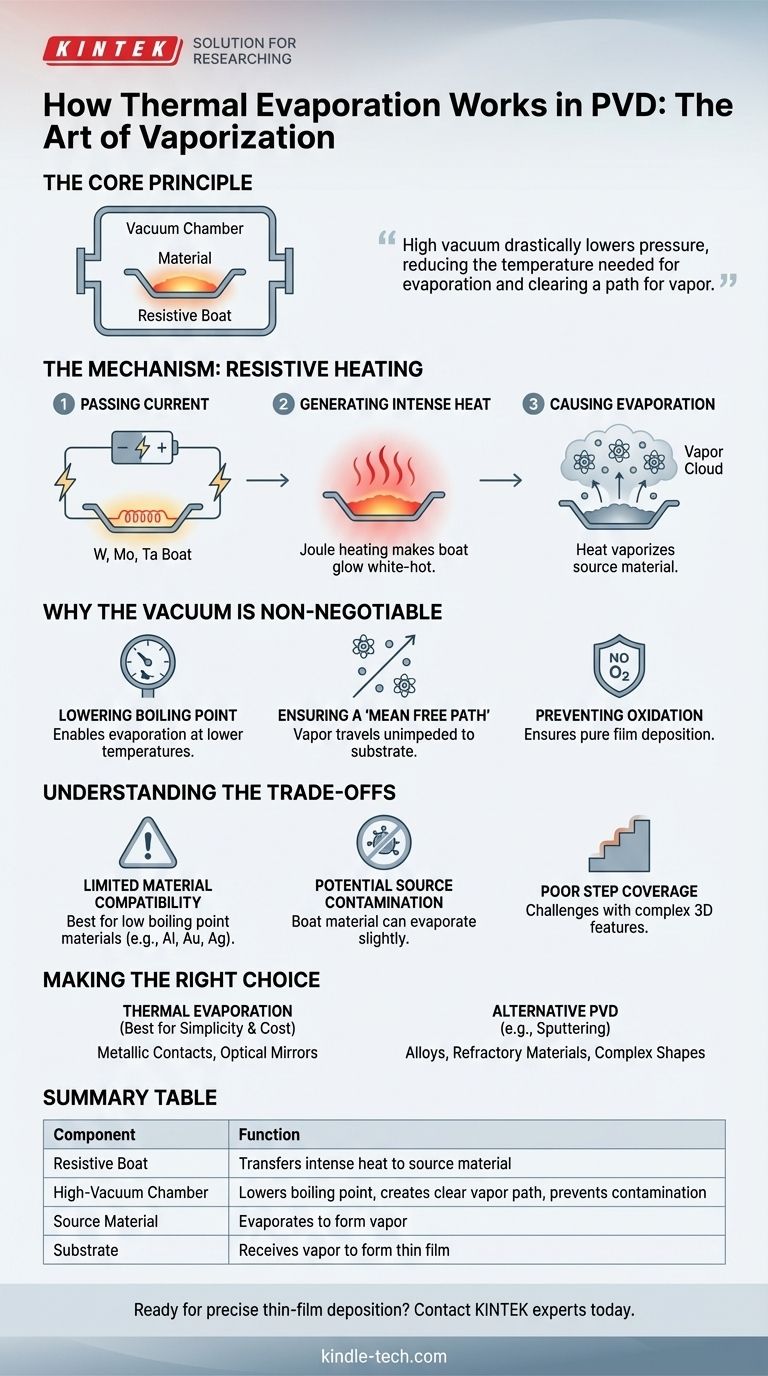

In thermal evaporation, the source material is vaporized by placing it in a container, often called a "boat," which is then heated to a very high temperature using electrical resistance. This process is conducted inside a high-vacuum chamber, which lowers the material's boiling point and allows the resulting vapor to travel unimpeded to the substrate, where it condenses to form a thin film.

The core principle is not just about heating the material until it boils. It's about using a high vacuum to drastically lower the pressure, which in turn reduces the temperature needed for evaporation and clears a path for the vapor to travel directly to the target.

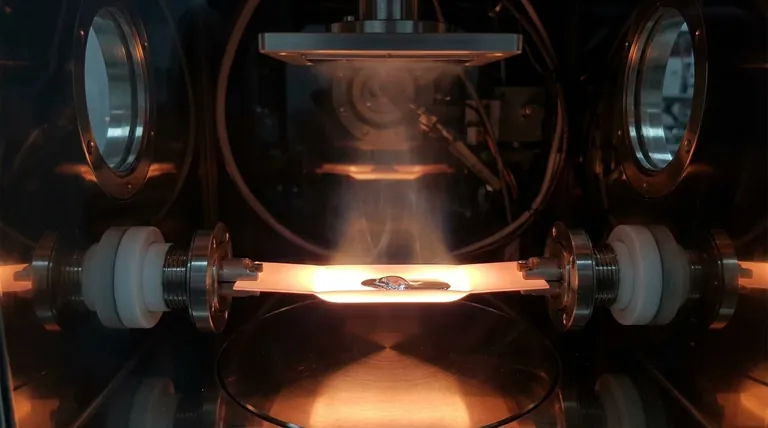

The Core Mechanism: Resistive Heating

Thermal evaporation is one of the simplest forms of Physical Vapor Deposition (PVD) because its vaporization mechanism is straightforward. It relies on a principle known as Joule heating.

Passing Current Through a "Boat" or "Filament"

The process begins with a small crucible, often shaped like a boat or a coil filament. This boat is made from a refractory metal with a very high melting point, such as tungsten, molybdenum, or tantalum. The source material you wish to deposit is placed inside this boat.

Generating Intense Heat

A high electrical current is then passed directly through the boat. Due to the boat material's inherent electrical resistance, the flow of current generates immense heat, causing it to glow white-hot. This is the same principle that makes the filament in an old incandescent light bulb glow.

Transferring Heat and Causing Evaporation

This intense heat is transferred to the source material via conduction. As the source material's temperature rises, its atoms gain enough thermal energy to break their bonds and escape from the surface as a vapor. This creates a cloud of vapor with significant pressure inside the vacuum chamber.

Why the Vacuum is Non-Negotiable

The high-vacuum environment is not just a container for the process; it is a critical and active component that enables thermal evaporation to work effectively.

Lowering the Boiling Point

Every material's boiling point is dependent on the surrounding pressure. By creating a high vacuum (removing almost all the air), the pressure inside the chamber is reduced by many orders of magnitude. This drastically lowers the temperature required for the source material to evaporate, making the process achievable without melting the entire system.

Ensuring a "Mean Free Path"

A vacuum removes air molecules (like nitrogen and oxygen) that would otherwise get in the way. This creates a long "mean free path," meaning the evaporated source atoms can travel in a straight line from the boat to the substrate without colliding with other gas particles. This is essential for creating a uniform and predictable film.

Preventing Oxidation and Contamination

At the high temperatures used in evaporation, most materials would instantly react with oxygen in the air, forming oxides and other impurities. The vacuum environment is inert, preventing this unwanted chemical reaction and ensuring the film deposited on the substrate is pure source material.

Understanding the Trade-offs

While simple and effective for many applications, thermal evaporation has important limitations that define when it is the right or wrong choice.

Limited Material Compatibility

This method works best for materials with relatively low boiling points, such as aluminum, gold, silver, and chromium. It is not suitable for materials with very high boiling points (like tungsten itself) or for compounds that decompose at high temperatures instead of evaporating cleanly.

Potential for Source Contamination

The heating element (the boat or filament) can also evaporate slightly during the process. This can introduce a small amount of contamination from the boat material (e.g., tungsten) into the deposited film, which may be unacceptable for high-purity applications.

Poor Step Coverage

Because the vapor travels in a straight "line-of-sight" from the source to the substrate, it cannot easily coat the sides of microscopic features or complex 3D topographies. This results in poor "step coverage" compared to other PVD methods like sputtering.

Making the Right Choice for Your Goal

Selecting the correct deposition technique depends entirely on your material, substrate, and final objective.

- If your primary focus is simplicity and cost for depositing single elements: Thermal evaporation is an excellent choice for applications like creating metallic contacts, optical mirrors, or decorative coatings.

- If your primary focus is depositing alloys, refractory materials, or coating complex shapes: You should consider alternative PVD methods like magnetron sputtering, which offers better control over stoichiometry and superior step coverage.

Ultimately, understanding the fundamental mechanism of vaporization empowers you to select the most efficient tool for your specific thin-film application.

Summary Table:

| Key Component | Function in Vaporization |

|---|---|

| Resistive Boat/Filament | Heated by electrical current to transfer intense heat to source material |

| High-Vacuum Chamber | Lowers boiling point, creates clear vapor path, prevents contamination |

| Source Material | Heated until atoms gain enough energy to escape as vapor |

| Substrate | Receives vapor that condenses into a thin film |

Ready to achieve precise thin-film deposition in your lab?

KINTEK specializes in high-quality lab equipment and consumables for all your PVD needs. Whether you're working with thermal evaporation for metallic contacts or require more advanced systems for complex materials, our experts can help you select the perfect solution for your specific application.

Contact us today to discuss your project requirements and discover how our reliable equipment can enhance your research and production outcomes!

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What is the difference between sputtering and thermal evaporation? Choose the Right PVD Method for Your Thin Film

- What is the meaning of thermal evaporation? A Guide to Simple, Cost-Effective Thin Film Coating

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications

- What is thermal evaporation used to deposit? A Guide to Metals, Compounds, and Key Applications

- What is thermal effect via evaporation? A Simple Guide to Thin-Film Deposition