In short, yes. A Physical Vapor Deposition (PVD) finish is exceptionally durable. It is renowned for being one of the most resilient coatings available, providing a surface that is significantly harder and more resistant to scratches, corrosion, and tarnishing than traditional finishing methods like electroplating or powder coating.

The core reason for PVD's durability is not its thickness, but its process. PVD molecularly bonds a thin layer of metal alloys to a surface, creating a finish that is an integral part of the object rather than a simple topcoat, resulting in superior hardness and longevity.

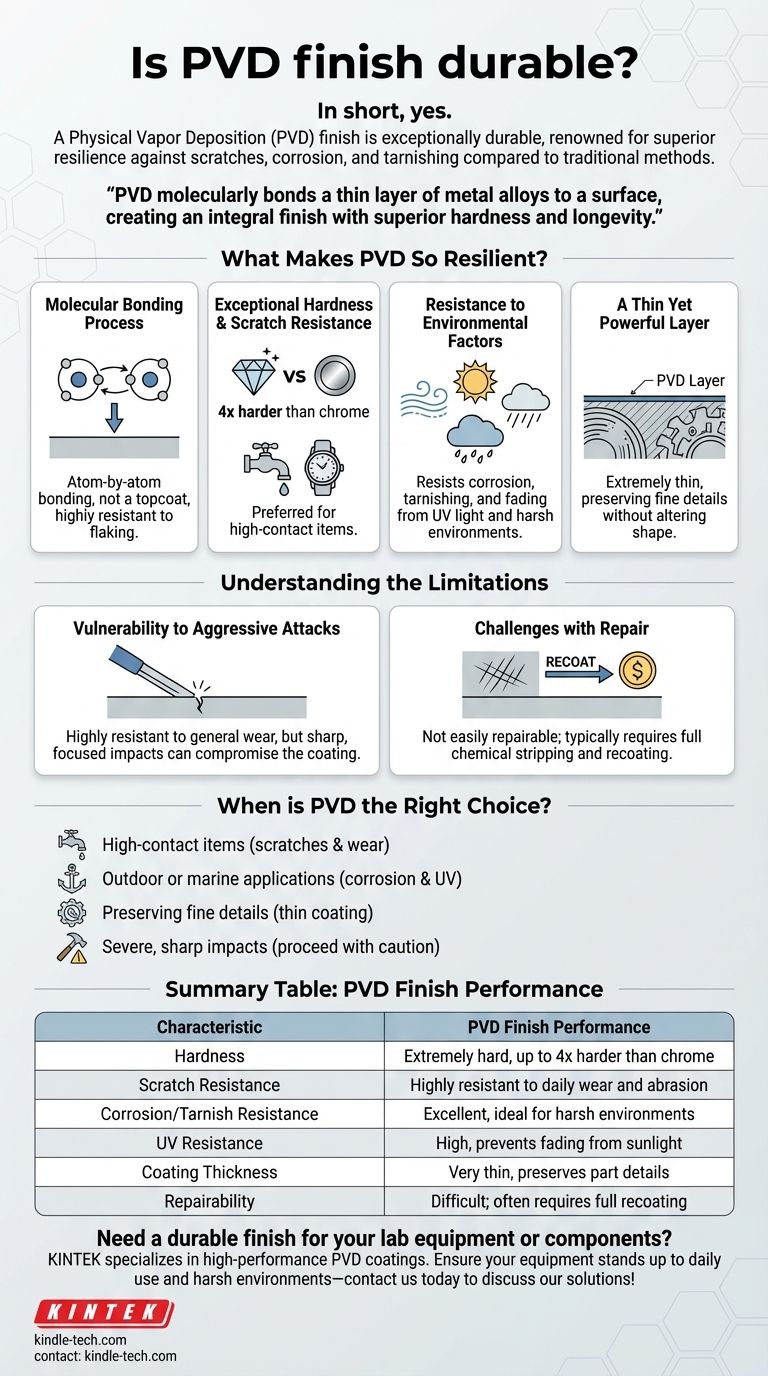

What Makes PVD So Resilient?

The durability of a PVD finish stems from the unique physics of its application process, which imparts several key characteristics.

The Molecular Bonding Process

PVD is not a paint, powder, or plating. It is a vacuum deposition process where the material is vaporized and then bonded to the substrate atom by atom.

This creates a finish that doesn't just sit on top of the surface; it becomes part of the substrate itself, making it highly resistant to flaking or chipping.

Exceptional Hardness and Scratch Resistance

The resulting PVD layer is extremely hard. Many sources cite PVD coatings as being four times harder than chrome, making them incredibly resistant to daily wear and scratching.

This is why PVD is a preferred finish for high-contact items like faucets, door hardware, and watches.

Resistance to Environmental Factors

PVD coatings are highly resistant to corrosion, tarnishing, and fading from UV light.

This makes them ideal for components exposed to harsh environments, such as outdoor fixtures or hardware used in coastal areas with salt in the air. The finish will remain vibrant and intact for years.

A Thin Yet Powerful Layer

Despite its strength, a PVD coating is extremely thin.

This is a significant advantage as it allows the original texture and fine details of the underlying product to show through. It provides a robust protective layer without altering the part's shape or dimensions, often eliminating the need for a secondary clear coat.

Understanding the Limitations

While PVD is a superior finish, it is not indestructible. Understanding its limitations is key to making an informed decision.

Vulnerability to Aggressive Attacks

The finish is highly resistant to abrasion and scratches from general use. However, a sharp, focused impact can still compromise the coating.

If a tool or sharp object strikes the surface with enough force, it can breach the thin PVD layer and damage the substrate beneath it.

Challenges with Repair

If a PVD finish does get significantly damaged, it is not easily repairable.

Unlike paint that can be touched up, a compromised PVD coating cannot be patched. Repairing the damage typically requires the entire object to be chemically stripped and then completely recoated, which can be costly and impractical.

When is PVD the Right Choice?

Choosing PVD depends entirely on your project's demands for longevity and performance.

- If your primary focus is high-contact items: PVD is an ideal choice for things like faucets, tools, and door handles due to its superior resistance to scratches and wear.

- If your primary focus is outdoor or marine applications: Its excellent corrosion and UV resistance make it a top-tier option for components exposed to the elements.

- If your primary focus is preserving fine details: The thinness of the coating makes it perfect for intricate parts where traditional, thicker coatings would obscure the design.

- If the item may be subject to severe, sharp impacts: Proceed with caution, as a deep gouge cannot be easily repaired and may require a full replacement.

Ultimately, a PVD finish provides a level of durability that far surpasses most traditional methods, making it a premier choice for applications where long-term appearance and resilience are critical.

Summary Table:

| Characteristic | PVD Finish Performance |

|---|---|

| Hardness | Extremely hard, up to 4x harder than chrome |

| Scratch Resistance | Highly resistant to daily wear and abrasion |

| Corrosion/Tarnish Resistance | Excellent, ideal for harsh environments |

| UV Resistance | High, prevents fading from sunlight |

| Coating Thickness | Very thin, preserves part details |

| Repairability | Difficult; often requires full recoating |

Need a durable finish for your lab equipment or components? KINTEK specializes in high-performance PVD coatings that provide exceptional hardness, corrosion resistance, and longevity for your laboratory needs. Ensure your equipment stands up to daily use and harsh environments—contact us today to discuss how our PVD solutions can enhance your products' durability and performance!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Touchscreen Automatic Vacuum Heat Press

- Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

People Also Ask

- What is a sputtering system? Achieve Unmatched Thin Film Deposition for Your Lab

- How many types of vapor phase deposition techniques are present? PVD vs. CVD Explained

- What are the effects of magnetron sputtering? Achieve High-Quality, Durable Thin Films for Your Lab

- What is magnetron sputtering machine? Precision Thin-Film Deposition for Advanced Materials

- Is sputtering a PVD? Discover the Key Coating Technology for Your Lab