In short, no. Silicon carbide (SiC) is not considered a good electrical insulator. Instead, it is a semiconductor, a class of material whose unique value comes from its ability to control the flow of electricity, not simply block it. While it can resist electrical current under certain conditions, its primary role in modern technology is active, not passive.

The core misunderstanding is in classification. Silicon carbide is not used for insulation; it is used for high-performance electronics. Its true value lies in being a wide-bandgap semiconductor, which allows it to operate at higher voltages, temperatures, and frequencies than traditional silicon.

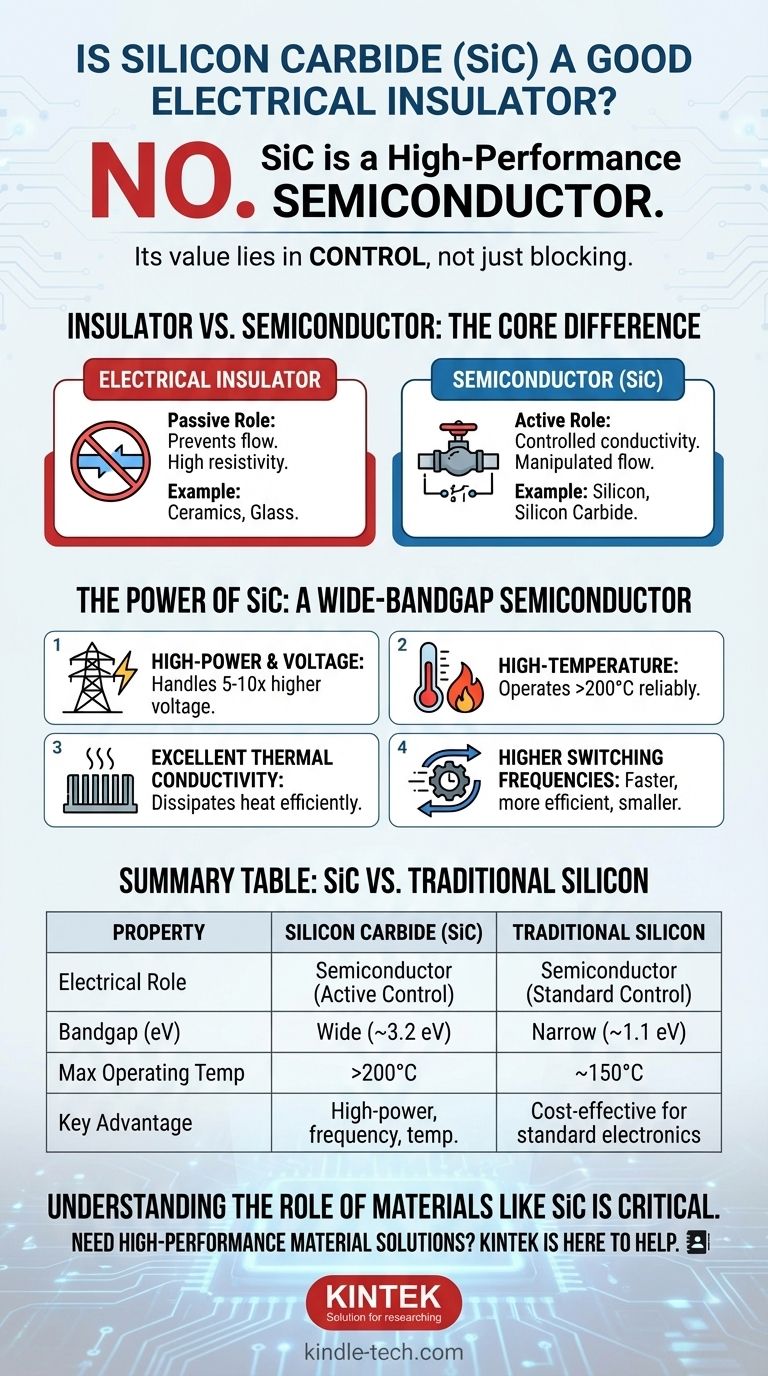

Insulator vs. Semiconductor: A Critical Distinction

To understand silicon carbide's role, we must first clarify the fundamental difference between an electrical insulator and a semiconductor.

What Defines an Electrical Insulator?

An electrical insulator is a material with very high electrical resistivity. Its atomic structure holds electrons tightly, preventing them from moving freely.

The primary function of an insulator is simple: to prevent the flow of electricity. Materials like glass, rubber, and most ceramics (like alumina) excel in this passive, blocking role.

What Defines a Semiconductor?

A semiconductor, as the name implies, has properties that fall between those of a conductor and an insulator. Its conductivity is not fixed.

The defining feature of a semiconductor is that its electrical conductivity can be precisely controlled and manipulated. This is typically done by introducing specific impurities (a process called doping) or by applying an electric field.

Where Silicon Carbide Fits In

Silicon carbide is a premier wide-bandgap semiconductor. The "bandgap" is the energy required to excite an electron so it can conduct electricity.

SiC's wide bandgap means it can withstand much stronger electric fields and higher temperatures before it breaks down and allows current to flow uncontrollably. This is precisely what makes it so valuable for electronics, not for insulation.

Why SiC's Semiconductor Properties Are So Valuable

The characteristics mentioned in material science—thermal stability, hardness, and chemical resistance—are what enable SiC to function as a superior semiconductor in demanding environments.

High-Power and High-Voltage Capability

SiC’s wide bandgap allows it to handle voltages 5-10 times higher than traditional silicon. This makes it essential for high-power applications like electric vehicle inverters and grid-scale power converters.

Superior High-Temperature Performance

While silicon-based electronics typically fail above 150°C, SiC devices can operate reliably at temperatures exceeding 200°C. This robustness is critical for automotive, aerospace, and down-hole drilling applications.

Excellent Thermal Conductivity

Paradoxically, while it can withstand high heat, SiC is also very good at dissipating it. This high thermal conductivity allows heat to be drawn away from active electronic components quickly, preventing overheating and improving reliability.

Higher Switching Frequencies

SiC devices can switch on and off much faster than silicon-based ones. This efficiency leads to smaller, lighter, and more energy-efficient power supplies, chargers, and inverters.

Understanding the Trade-offs and Misconceptions

While powerful, SiC is not a universal solution. Understanding its limitations is key to using it correctly.

It Is Not a Passive Blocker

The most common misconception is viewing SiC through an insulator lens. Its purpose is not to simply block all current. It is engineered to control current with extreme precision under conditions that would destroy lesser materials.

Manufacturing Complexity and Cost

Producing high-purity, single-crystal SiC wafers is significantly more difficult and expensive than producing silicon wafers. This cost is a major trade-off that limits its use to applications where its performance benefits are essential.

Brittleness and Mechanical Properties

As noted, silicon carbide is very hard but also brittle. This mechanical property must be carefully managed during the design and manufacturing of SiC-based components to prevent cracking and failure.

Making the Right Choice for Your Application

Choosing the right material depends entirely on its intended electrical function.

- If your primary focus is pure electrical isolation: You need a true insulator. Materials like alumina ceramic, glass, mica, or specific polymers are the correct choice.

- If your primary focus is high-power, high-frequency, or high-temperature electronics: Silicon carbide is an exceptional choice for components like MOSFETs and diodes in electric vehicles, solar inverters, and industrial power supplies.

- If your primary focus is structural integrity in extreme heat: Certain grades of SiC ceramic are used in non-electrical roles like kiln furniture or heat exchangers, where its thermal properties are key and its electrical behavior is secondary.

Ultimately, silicon carbide's role is defined by control, enabling a new generation of powerful and efficient electronics, which is the opposite goal of an insulator.

Summary Table:

| Property | Silicon Carbide (SiC) | Traditional Silicon |

|---|---|---|

| Electrical Role | Semiconductor | Semiconductor |

| Bandgap (eV) | Wide (~3.2) | Narrow (~1.1) |

| Max Operating Temperature | >200°C | ~150°C |

| Key Advantage | High-power, high-frequency control | Cost-effective for standard electronics |

Need a material solution for your high-performance application?

Understanding the precise role of materials like silicon carbide is critical to your project's success. Whether you require robust components for high-temperature environments or expert guidance on material selection for your lab's equipment, KINTEK is here to help.

As a specialist in lab equipment and consumables, we provide not only high-quality materials but also the technical expertise to ensure they meet your specific needs. Let our experts help you leverage the right materials for superior results.

Contact our team today to discuss your application and discover how KINTEK can support your laboratory's innovation.

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Optical Window Glass Substrate Wafer Single Double Sided Coated K9 Quartz Sheet

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

People Also Ask

- What are 3 products that carbon nanotubes can be used in? Enhancing Batteries, Tires, and Composites

- What are the potential applications of carbon nanotubes? Enhance Battery, Composite, and Electronic Performance

- What is the ideal operating environment for a glassy carbon sheet? Ensure Optimal Performance and Longevity

- What applications is carbon felt suitable for? Ideal for High-Performance Electrochemical Systems

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose