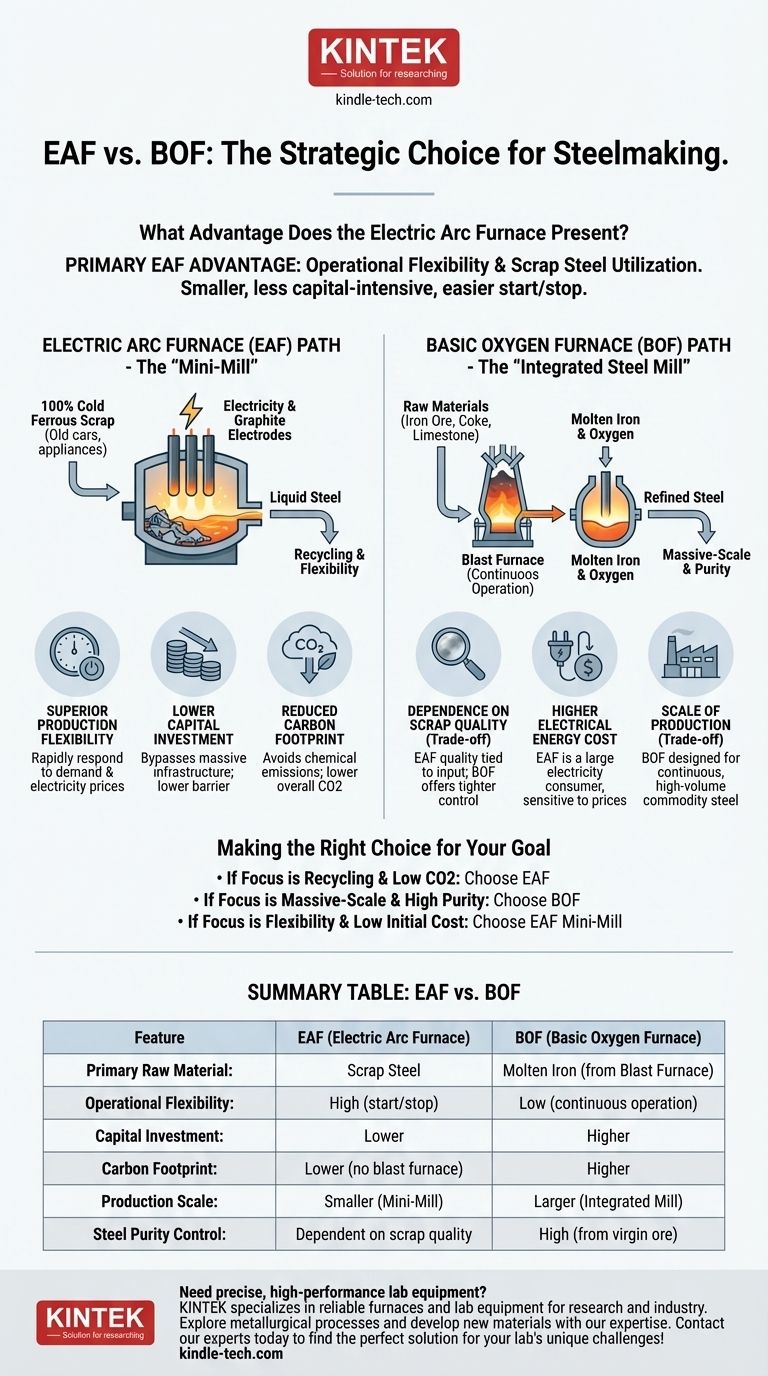

The primary advantage of an electric arc furnace (EAF) is its operational flexibility, driven by its ability to use scrap steel as its main raw material. This allows for smaller, less capital-intensive production that can be started and stopped more easily than the massive, integrated process required for a basic oxygen furnace (BOF), which relies on molten iron from a blast furnace.

The choice between an EAF and a BOF is not a matter of which is universally superior, but a strategic decision based on raw material availability, required production scale, capital investment, and environmental considerations. The EAF excels in a world prioritizing recycling and flexibility, while the BOF is built for massive-scale production from virgin ore.

The Fundamental Difference: Raw Materials

To understand the advantages of each furnace, we must first look at what goes into them. This core difference in input dictates everything from cost and scale to environmental impact.

The Basic Oxygen Furnace (BOF) Path

A BOF is part of a larger, integrated steel mill. Its primary input is not scrap, but hot metal—molten iron produced in a blast furnace.

This process starts with raw materials like iron ore, coke (a high-carbon fuel derived from coal), and limestone. The blast furnace creates the molten iron, which is then charged into the BOF to be refined into steel.

The Electric Arc Furnace (EAF) Path

An EAF is the centerpiece of a "mini-mill" and functions as a powerful recycling unit. Its primary input is 100% cold ferrous scrap—old cars, appliances, and industrial offcuts.

Instead of a chemical reaction with oxygen to generate heat, the EAF uses massive graphite electrodes to pass an electrical current through the scrap, melting it into liquid steel.

Key Advantages of the Electric Arc Furnace

The EAF's reliance on scrap steel and electricity creates several distinct operational and economic advantages over the traditional integrated mill route.

Superior Production Flexibility

EAFs can be started and stopped relatively quickly. This allows steelmakers to respond rapidly to market demand and fluctuating electricity prices, operating only when it is most profitable.

A blast furnace, by contrast, is designed for continuous operation, often running for years without stopping. Shutting it down is a costly and complex undertaking.

Lower Capital Investment

Building an EAF "mini-mill" is significantly cheaper and faster than constructing an integrated mill. It completely bypasses the need for the massive and expensive infrastructure of coke ovens and blast furnaces.

This lower barrier to entry has allowed for a more decentralized and competitive steel industry.

Reduced Carbon Footprint

The integrated BOF process is carbon-intensive, particularly the blast furnace stage where coke is used to reduce iron ore. This process is a major source of industrial CO2 emissions.

The EAF process avoids these chemical emissions entirely. While it consumes a great deal of electricity, its overall carbon footprint is significantly lower, especially when powered by a grid with a high percentage of renewable energy.

Understanding the Trade-offs

The advantages of the EAF do not come without limitations. Objectivity requires acknowledging where the BOF process retains an edge.

Dependence on Scrap Quality

The quality of steel produced in an EAF is directly tied to the quality of the scrap metal fed into it. Contaminants in the scrap, known as "residuals," can be difficult and costly to remove.

The BOF process, starting with virgin iron ore, offers much tighter control over the steel's final chemistry, making it traditionally better for producing the highest-purity and most demanding grades of steel.

Higher Electrical Energy Cost

While the overall process is often cited as more energy-efficient, the EAF furnace itself is an enormous consumer of electricity. This makes EAF steelmakers highly sensitive to regional electricity prices and grid stability.

Scale of Production

BOFs are typically much larger than EAFs and are designed for the continuous, high-volume production of commodity steel. A single large integrated mill can produce quantities of steel that would require multiple EAF mini-mills to match.

Making the Right Choice for Your Goal

The best steelmaking technology is entirely dependent on the strategic objective.

- If your primary focus is leveraging recycled materials and minimizing CO2 emissions: The Electric Arc Furnace is the definitive choice due to its use of scrap and avoidance of the blast furnace process.

- If your primary focus is massive-scale production of high-purity steel from raw ore: The traditional Basic Oxygen Furnace route provides superior control over chemistry and is unmatched for sheer volume.

- If your primary focus is production flexibility and lower initial capital cost: The EAF "mini-mill" model offers a faster, cheaper, and more agile entry into the steel market.

Ultimately, understanding these fundamental differences empowers you to select the right tool for the specific industrial goal.

Summary Table:

| Feature | Electric Arc Furnace (EAF) | Basic Oxygen Furnace (BOF) |

|---|---|---|

| Primary Raw Material | Scrap Steel | Molten Iron (from Blast Furnace) |

| Operational Flexibility | High (can start/stop) | Low (continuous operation) |

| Capital Investment | Lower | Higher |

| Carbon Footprint | Lower (no blast furnace) | Higher |

| Production Scale | Smaller (Mini-Mill) | Larger (Integrated Mill) |

| Steel Purity Control | Dependent on scrap quality | High (from virgin ore) |

Need precise, high-performance lab equipment for your materials testing or process development? KINTEK specializes in supplying reliable furnaces and lab equipment tailored to the needs of research and industrial laboratories. Whether you're exploring metallurgical processes or developing new materials, our expertise can help you achieve accurate and efficient results. Contact our experts today to find the perfect solution for your lab's unique challenges!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- How does a sputtering system work? Achieve Superior Thin-Film Deposition for Your Lab

- What is the necessity of using a laboratory drying oven when processing MoO3/GO composite nanopowders? Find out here.

- How do you clean a sputtering chamber? Master the Critical Protocol for Purity and Yield

- How does a precision centrifuge contribute to electrochemical wastewater analysis? Ensure Data Integrity and Accuracy

- How does heat treatment affect material selection? Choose the Right Alloy for Your Desired Properties

- What are three potential solutions to the plastic waste problem? A Guide to Recycling, Bioplastics & Upcycling

- What is the purpose of vacuum filtration equipment in gallium leaching? Achieve Rapid Solid-Liquid Separation Efficiency

- What are the basic characteristics requirements in heat treatment? Master Temperature, Time, and Cooling