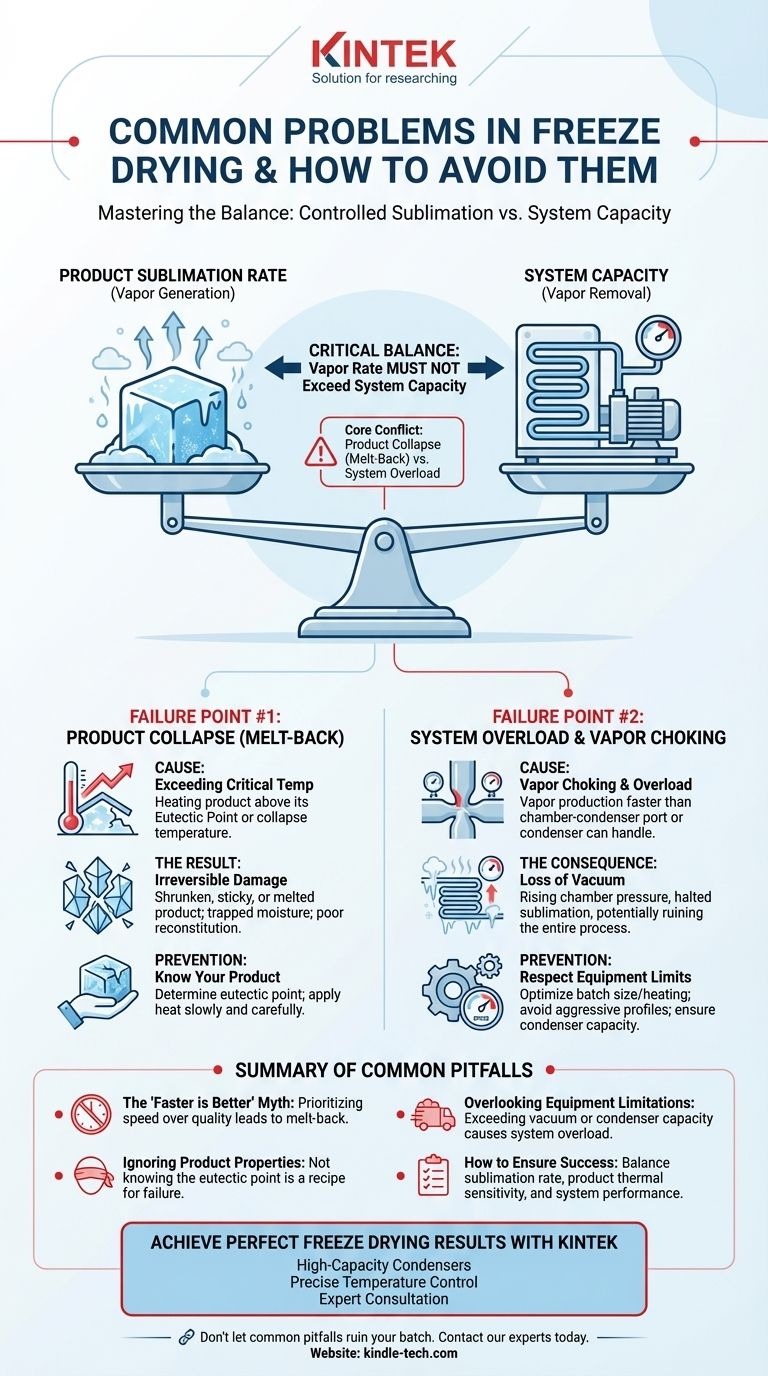

Successful freeze drying is a process of controlled sublimation, and failure almost always stems from losing that control. The most common problems are heating the product too quickly, which causes structural collapse (melt-back), and overwhelming the system with too much water vapor, leading to condenser overload and a loss of vacuum.

The core challenge in all freeze drying is maintaining a delicate balance. The rate at which water vapor leaves your product (the sublimation rate) must never exceed your equipment's capacity to remove and collect that vapor.

The Core Conflict: Sublimation vs. System Capacity

Freeze drying, or lyophilization, preserves a product's structure by removing water under specific conditions. Understanding the two sides of this process—the product and the machine—is the key to avoiding problems.

What Happens in the Product

First, the product is frozen solid. A deep vacuum is then applied, and under this low pressure, the ice turns directly into a gas (sublimation) without first melting into a liquid. This is what preserves the product's delicate structure.

The System's Two Critical Jobs

The freeze dryer itself has two main responsibilities. First, it must create and maintain the deep vacuum. Second, its refrigerated condenser coils must be cold enough to act as a trap, capturing the water vapor and turning it back into ice, effectively removing it from the system.

Critical Failure Point #1: Product Collapse (Melt-Back)

The most visible sign of a failed batch is a shrunken, sticky, or melted product. This is an irreversible failure caused by a loss of structural integrity during the drying process.

The Cause: Exceeding the Critical Temperature

To speed up sublimation, heat is slowly applied to the product shelves. However, if the product's temperature rises above its unique critical point, the frozen structure will collapse or melt even while under vacuum.

Understanding the Eutectic Point

For crystalline products, this threshold is called the eutectic point. This is the lowest possible melting temperature for the material. Operating above this temperature guarantees failure. It is the absolute "do-not-cross" thermal line for your product during primary drying.

The Result: A Ruined Batch

Once collapse occurs, the product loses its porous structure. This traps remaining moisture, dramatically slows drying, and results in a product that will not properly reconstitute and has lost its original characteristics.

Critical Failure Point #2: System Overload

Even if you manage the product temperature perfectly, you can still ruin the process by overwhelming the equipment designed to handle the water vapor.

The Problem of Vapor Choking

Vapor choking happens when your product produces water vapor faster than the port connecting the chamber to the condenser can handle. This creates a bottleneck, causing chamber pressure to rise. A rising pressure is the enemy of sublimation.

The Consequence: Condenser Overload

If too much vapor gets past the choke point or the sublimation rate is simply too high, it can overwhelm the condenser. The condenser's job is to freeze the vapor. If its capacity or refrigeration power is inadequate, it can't trap the vapor fast enough, leading to a rise in system pressure and a potential halt to the entire process.

Common Pitfalls to Avoid

Mistakes in freeze drying often stem from a desire to speed up the cycle without respecting the physical limitations of the product or the equipment.

The "Faster is Better" Myth

The most common error is applying too much shelf heat too early in an attempt to shorten the cycle. This is the primary cause of melt-back and is a trade-off that sacrifices quality for a perceived gain in speed.

Ignoring Your Product's Properties

Every formulation has a unique eutectic point or collapse temperature. Proceeding without knowing this critical value is like navigating without a map. You are guessing at the single most important process parameter.

Overlooking Equipment Limitations

You cannot run a process that your machine cannot handle. An overloaded product chamber or an aggressive heating profile can easily exceed the condenser's rated capacity or the vacuum pump's ability to maintain pressure, leading to system overload.

How to Ensure a Successful Cycle

A successful outcome depends on carefully balancing the sublimation rate with your product's thermal sensitivity and your system's performance.

- If your primary focus is product quality: Prioritize keeping the product temperature well below its eutectic or collapse point, even if this significantly extends the cycle time.

- If your primary focus is process efficiency: Ensure your batch size and heating profile do not generate vapor at a rate that exceeds your condenser's capacity or causes vapor choking.

- If you are developing a new process: First, determine your product's critical temperature to establish a safe operating limit before you attempt a full-scale run.

By treating freeze drying as a controlled and balanced energy transfer, you can consistently achieve perfectly preserved results.

Summary Table:

| Problem | Cause | Consequence | Prevention |

|---|---|---|---|

| Product Collapse (Melt-Back) | Heating product above its critical temperature (eutectic point). | Irreversible structural damage, trapped moisture, poor reconstitution. | Know your product's eutectic point; apply heat slowly and carefully. |

| System Overload | Vapor production rate exceeds condenser capacity or causes choking. | Loss of vacuum, halted process, failed batch. | Respect equipment limits; avoid overloading the chamber or aggressive heating. |

| Vapor Choking | Vapor flow bottleneck at the chamber-condenser port. | Rising chamber pressure, slowed/stopped sublimation. | Optimize batch size and heating profile to match port size. |

Achieve Perfect Freeze Drying Results with KINTEK

Struggling with product collapse or system overload? Your success hinges on the delicate balance between your product's properties and your equipment's capabilities. KINTEK specializes in providing reliable lab freeze dryers and expert support tailored to your specific laboratory needs.

We offer:

- High-Capacity Condensers: Designed to handle high vapor loads efficiently, preventing system overload.

- Precise Temperature Control: Ensure your product never exceeds its critical eutectic point.

- Expert Consultation: Our team can help you determine your product's critical parameters and optimize your lyophilization cycle for maximum quality and efficiency.

Don't let common pitfalls ruin your batch. Contact our experts today to find the perfect freeze drying solution for your lab!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why is a freeze dryer preferred for drying nickel nanoparticle precursors? Prevent Hard Agglomeration Now

- What is the function of Freeze-thaw Equipment in Au-(PNiPAAm/PVA) hydrogel? Achieve High-Speed Photothermal Actuation

- What is the function of a freeze dryer in the ice-templating process? Preserving Aligned Pore Scaffolds for LAGP

- What role does a laboratory freeze dryer play in the synthesis of graphene-based electrocatalysts? Preserve 3D Structures

- What are the advantages of using freeze drying for phase change materials with biopolymer shells? Optimize Stability