To properly use a laboratory freeze dryer, you must treat it as a controlled scientific process, not just a piece of equipment. The core principles involve ensuring your sample is completely frozen solid before applying a deep vacuum, diligently maintaining the vacuum system to enable sublimation, and monitoring the entire cycle to prevent sample melt-back or equipment damage.

The critical takeaway is that successful freeze-drying hinges on a delicate balance: the sample must remain frozen solid while a deep vacuum encourages water molecules to transition directly from a solid (ice) to a gas (vapor), bypassing the destructive liquid phase entirely. Every "do" supports this balance, and every "don't" threatens to disrupt it.

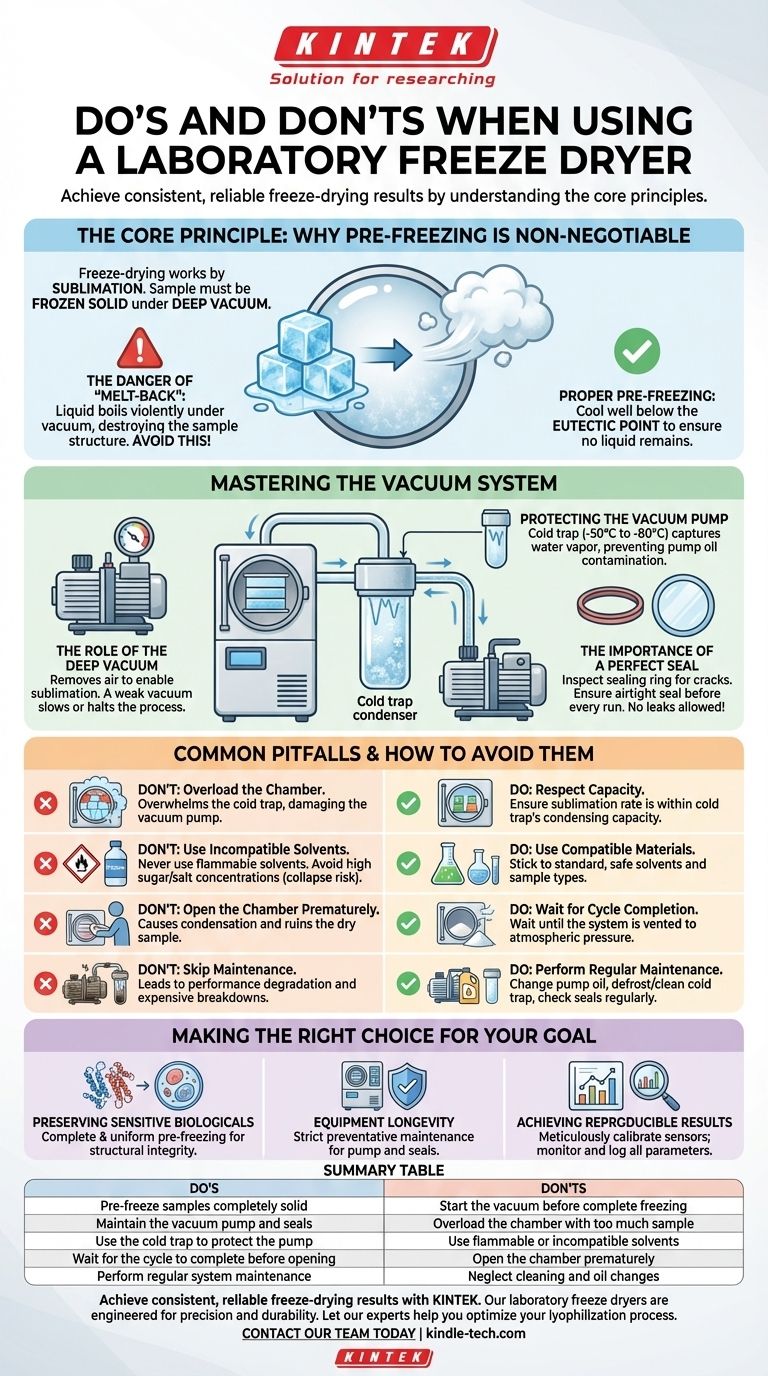

The Core Principle: Why Pre-Freezing is Non-Negotiable

The entire process of lyophilization, or freeze-drying, is built on a single physical principle. Understanding this is key to avoiding the most common and destructive errors.

Sublimation, Not Evaporation

Freeze-drying works by sublimation. It's the process where a substance, in this case, water, transitions directly from a solid to a gas without ever becoming a liquid.

This is only possible under very specific conditions of low temperature and low pressure (a deep vacuum).

The Danger of "Melt-Back"

If your sample is not frozen completely solid before you start the vacuum pump, disaster will strike.

Any liquid water will boil violently under the vacuum. This process, known as melt-back or collapse, will destroy the delicate structure of your sample, rendering the entire run a failure.

Proper Pre-Freezing Technique

Your sample must be cooled well below its eutectic point—the lowest possible melting temperature for its mixture of solutes.

This ensures no pockets of liquid remain that could boil and ruin the sample's structural integrity during the primary drying phase.

Mastering the Vacuum System

The vacuum pump and its associated components are the heart of the freeze dryer. Their proper function is essential for creating the low-pressure environment needed for sublimation.

The Role of the Deep Vacuum

The vacuum pump removes air molecules from the chamber. This low-pressure environment makes it much easier for the frozen water molecules to escape the sample as vapor.

A weak vacuum will significantly slow down or completely halt the drying process.

Protecting the Vacuum Pump

The cold trap (or condenser) is the most important component for protecting the pump. It is a surface cooled to a very low temperature (e.g., -50°C to -80°C) that sits between the sample chamber and the vacuum pump.

Water vapor sublimating from the sample freezes onto the cold trap, preventing it from entering and contaminating the vacuum pump oil, which would quickly degrade the pump's performance.

The Importance of a Perfect Seal

Even a minor leak will prevent the system from reaching the necessary deep vacuum.

Before every run, visually inspect the main rubber sealing ring for cracks or debris. Ensure the plexiglass cover sits cleanly and evenly to create an airtight seal.

Common Pitfalls and How to Avoid Them

Beyond the core principles, several common operational mistakes can lead to failed runs or equipment damage. Adhering to these guidelines is crucial for consistent success.

Do Not Overload the Chamber

Placing too much sample volume in the dryer at once can overwhelm the cold trap.

If the rate of sublimation is higher than the cold trap's capacity to condense the vapor, this moisture "passes through" and enters the vacuum pump, causing significant damage.

Do Not Use Incompatible Solvents

Never use flammable solvents like ethanol or acetone in a standard freeze dryer. The combination of a sealed chamber and electrical components creates a serious explosion risk.

Additionally, materials with high concentrations of sugars or salts can be difficult to freeze-dry, as they lower the melting point and can lead to a glassy, sticky collapse rather than a dry powder.

Do Not Open the Chamber Prematurely

Wait for the cycle to complete and for the system to be properly vented back to atmospheric pressure before attempting to open the chamber.

Opening the system while under vacuum or while samples are still cold will cause ambient, moisture-laden air to rush in, instantly condensing on your now-perfectly-dry sample.

Do Not Skip Maintenance

A freeze dryer requires regular attention. This includes changing the vacuum pump oil, defrosting and cleaning the cold trap after every run, and ensuring all valves and seals are in good working order.

Neglecting maintenance is the fastest way to degrade performance and cause expensive breakdowns.

Making the Right Choice for Your Goal

Your operational focus should align with your primary objective for using the freeze dryer.

- If your primary focus is preserving sensitive biologicals: Complete and uniform pre-freezing is the most critical step to maintain the structural integrity of proteins, cells, or tissues.

- If your primary focus is equipment longevity: A strict, preventative maintenance schedule for the vacuum pump and chamber seals is your best investment.

- If your primary focus is achieving reproducible results: Meticulously calibrate your temperature and pressure sensors and carefully monitor and log the parameters for every single run.

By understanding the principles behind the rules, you transform the procedure from a checklist of steps into a powerful and reliable scientific tool.

Summary Table:

| Do's | Don'ts |

|---|---|

| Pre-freeze samples completely solid | Start the vacuum before complete freezing |

| Maintain the vacuum pump and seals | Overload the chamber with too much sample |

| Use the cold trap to protect the pump | Use flammable or incompatible solvents |

| Wait for the cycle to complete before opening | Open the chamber prematurely |

| Perform regular system maintenance | Neglect cleaning and oil changes |

Achieve consistent, reliable freeze-drying results with KINTEK.

Our laboratory freeze dryers are engineered for precision and durability, ensuring your sensitive samples are preserved perfectly. From pharmaceuticals to biological research, KINTEK provides the equipment and expert support your lab needs.

Let our experts help you optimize your lyophilization process. Contact our team today to find the perfect freeze-drying solution for your laboratory.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why is a laboratory freeze-drying system essential for fermentation biomass? Preserve Sample Integrity for Analysis

- What is the function of Freeze-thaw Equipment in Au-(PNiPAAm/PVA) hydrogel? Achieve High-Speed Photothermal Actuation

- What is the function of a freeze dryer in the ice-templating process? Preserving Aligned Pore Scaffolds for LAGP

- Why is a laboratory vacuum freeze dryer essential for plant extracts? Preserve Bioactivity & Structure

- What is the purpose of an evaporator? The Key Component That Creates Cooling