In materials science, the four fundamental heat treatment methods are annealing, hardening, quenching, and stress relieving. Each process involves a carefully controlled cycle of heating and cooling designed to intentionally alter a metal's internal structure, thereby changing its physical and mechanical properties to fit a specific application.

The core purpose of heat treatment is not simply to heat metal, but to precisely manipulate its microscopic crystal structure. By controlling temperature and cooling rates, you can engineer desirable properties like softness for machining, extreme hardness for durability, or internal stability to prevent distortion.

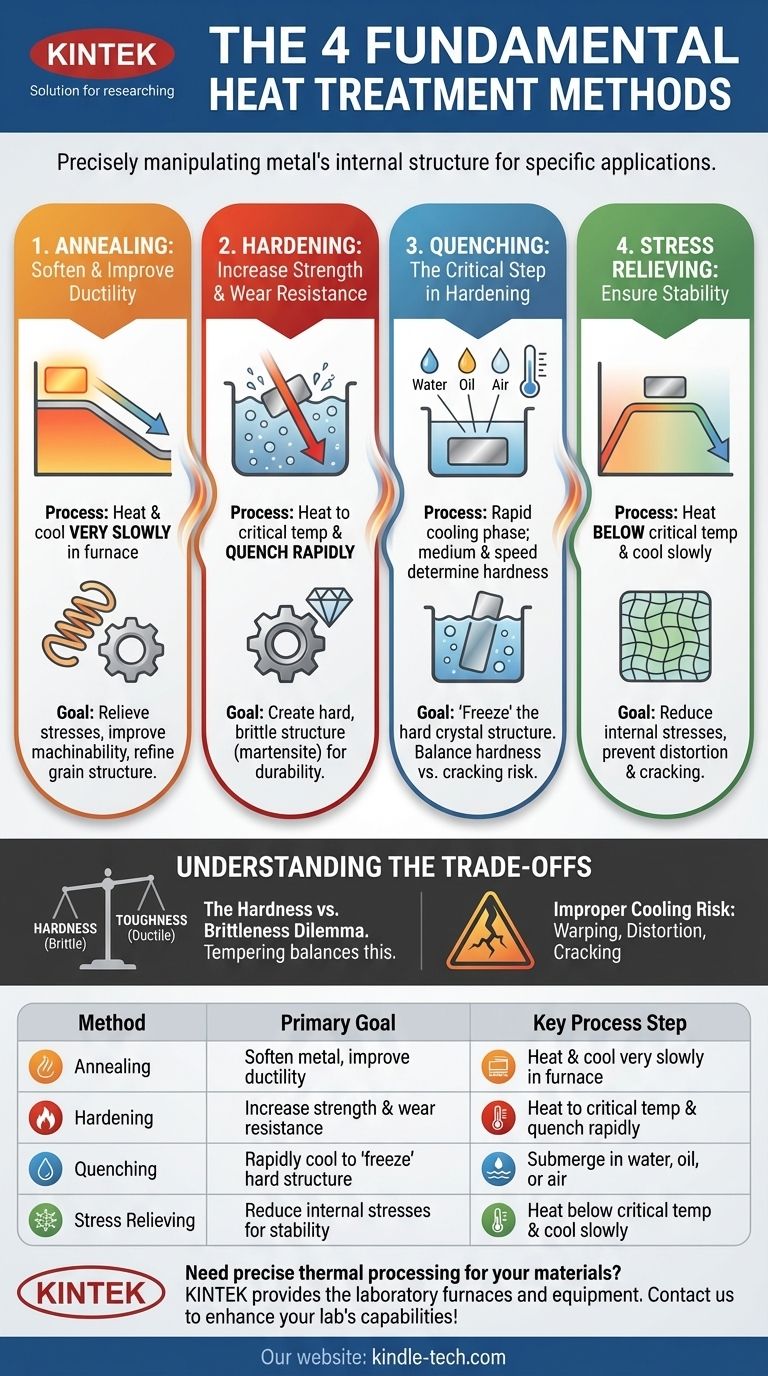

The Four Pillars of Heat Treatment

Each heat treatment method serves a distinct purpose. Understanding the goal of each is key to selecting the right one for your component. While there are many variations, they all derive from these core principles.

1. Annealing: To Soften and Improve Ductility

The primary goal of annealing is to make a metal as soft and ductile as possible. This is often done to relieve internal stresses, improve machinability, and refine the material's grain structure after it has been worked (e.g., bent or stamped).

The process involves heating the metal to a specific temperature, holding it there for a period, and then cooling it very slowly, often by leaving it in the furnace to cool down.

This slow cooling allows the material's internal crystals (grains) to reform into a uniform and stress-free state, resulting in a softer, more easily worked material.

2. Hardening: To Increase Strength and Wear Resistance

Hardening is performed to increase a material's strength, hardness, and resistance to wear. It is most commonly applied to medium and high-carbon steels.

The process involves heating the steel to a critical temperature where its crystal structure changes, and then cooling it rapidly.

This rapid cooling, known as quenching, freezes the crystal structure in a very hard, brittle state called martensite.

3. Quenching: The Critical Step in Hardening

While sometimes listed separately, quenching is the rapid cooling phase of the hardening process. The speed and medium of the quench are critical variables that determine the final hardness.

Common quenching mediums include water, brine, oil, and forced air. The choice depends on the type of steel and the desired balance between hardness and the risk of cracking.

A faster quench (e.g., in brine) produces a harder but more brittle part, while a slower quench (e.g., in oil) results in less hardness but also less internal stress and distortion.

4. Stress Relieving: To Ensure Stability

Stress relieving is used to reduce the internal stresses that may have been created during other manufacturing processes like welding, casting, or heavy machining.

These internal stresses can cause dimensional changes or cracking over time if not removed. The process involves heating the part to a temperature below its critical transformation point and holding it there.

After holding, the part is cooled slowly. This allows the internal stresses to relax without significantly changing the material's core hardness or structure, resulting in a stable and reliable component.

Understanding the Trade-offs

Heat treatment is a game of balancing properties. Improving one characteristic often comes at the expense of another.

The Hardness vs. Brittleness Dilemma

The most fundamental trade-off is between hardness and brittleness. A fully hardened steel is extremely strong and wear-resistant but is also very brittle, like glass.

This is why hardened parts are almost always tempered after quenching. Tempering is a secondary, lower-temperature heat treatment that reduces some of the brittleness at the cost of a small amount of hardness, achieving a tougher, more durable final part.

The Risk of Improper Cooling

The quenching phase is where most failures occur. If a part is cooled too quickly or unevenly, the immense internal stresses can cause it to warp, distort, or crack.

Choosing the correct quenching medium and ensuring proper agitation is critical for success, especially with complex geometries.

Time, Cost, and Necessity

Processes like annealing and stress relieving add time and cost to production. However, skipping them can lead to much more expensive problems later.

An un-annealed part might be too hard to machine efficiently, while a welded assembly that isn't stress-relieved could distort or fail in service.

Selecting the Right Process for Your Goal

Your choice of heat treatment must be directly tied to the intended function of the component.

- If your primary focus is improving machinability and ductility: Annealing is your required process to soften the material and make it easy to work with.

- If your primary focus is maximizing strength and wear resistance: Hardening, followed by tempering, is the necessary path to achieve a strong and tough final part.

- If your primary focus is ensuring dimensional stability after welding or machining: Stress relieving is a critical step to prevent future distortion or failure from internal stresses.

By understanding these fundamental processes, you can intentionally engineer materials to meet the precise demands of any application.

Summary Table:

| Method | Primary Goal | Key Process Step |

|---|---|---|

| Annealing | Soften metal, improve ductility | Heat & cool very slowly in furnace |

| Hardening | Increase strength & wear resistance | Heat to critical temp & quench rapidly |

| Quenching | Rapidly cool to 'freeze' hard structure | Submerge in water, oil, or air |

| Stress Relieving | Reduce internal stresses for stability | Heat below critical temp & cool slowly |

Need precise thermal processing for your materials? The right heat treatment is critical for achieving the desired hardness, strength, and stability in your components. KINTEK specializes in providing the laboratory furnaces and equipment necessary to execute these processes with precision and repeatability. Let our experts help you select the perfect solution for your annealing, hardening, or stress relieving needs. Contact us today to discuss how we can enhance your lab's capabilities!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the power rating of a muffle furnace? Choose the Right Voltage & Power for Your Lab

- What are the acceptance criteria for muffle furnace? Ensure Safety, Performance & Success

- How is a muffle furnace used for sample digestion? A Guide to Dry Ashing for Accurate Analysis

- How do you run a muffle furnace? Master the Step-by-Step Process for Safe, Precise Results

- How do you keep a sample in a muffle furnace? A Guide to Safe and Accurate Placement