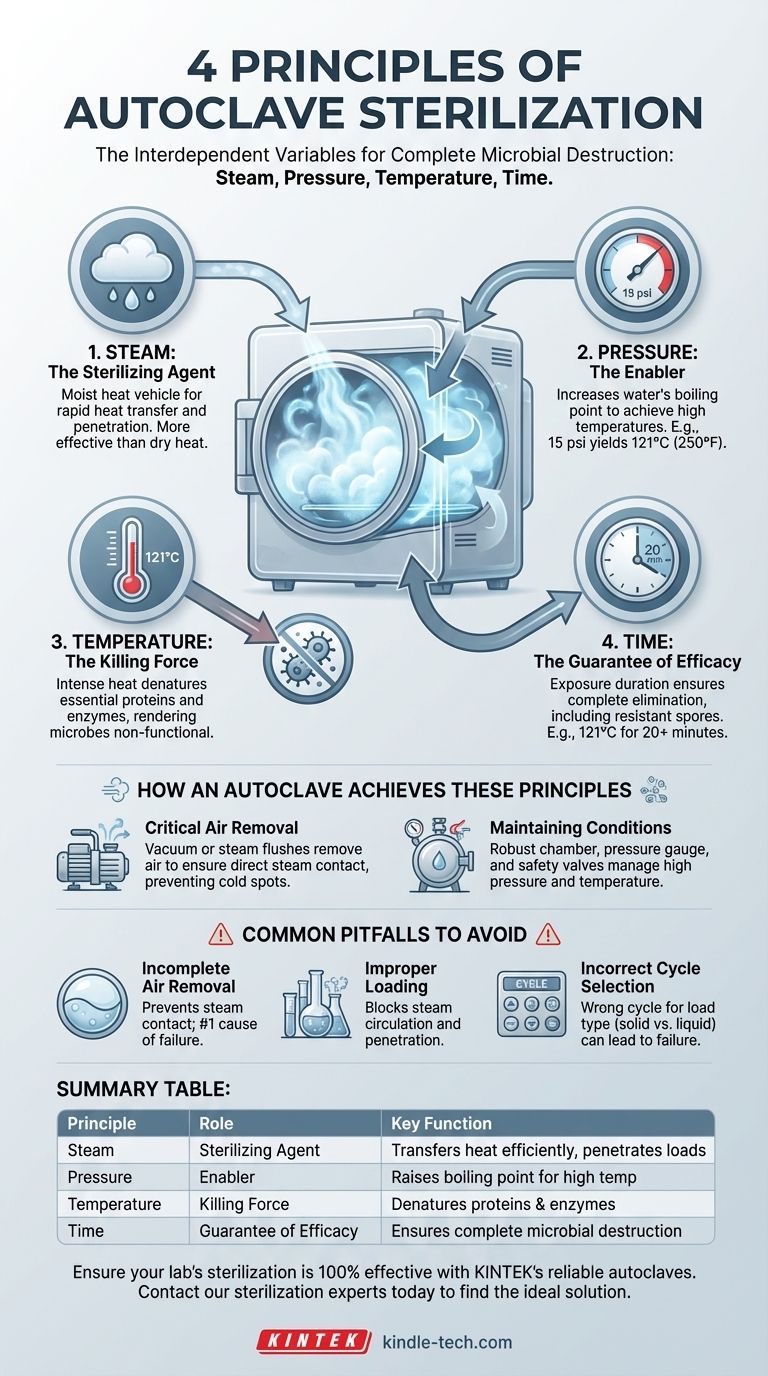

The four core principles of autoclaving are the interdependent variables of Steam, Pressure, Temperature, and Time. An autoclave does not simply heat items; it uses high-pressure steam as a medium to achieve lethal temperatures that, when held for a sufficient duration, guarantee the complete destruction of all microorganisms.

The central concept of autoclaving is that pressure is not the sterilizing agent itself. Instead, pressure is used to increase the boiling point of water, allowing the creation of high-temperature steam that can rapidly transfer lethal heat energy to every surface of the load.

The Core Principles of Steam Sterilization Explained

To achieve reliable sterilization, an autoclave must correctly manage four critical factors. The failure of any one principle will result in a failed sterilization cycle.

Principle 1: Steam as the Sterilizing Agent

Moist heat is significantly more effective at killing microbes than dry heat.

Steam is the vehicle that transfers this moist heat. It can hold and transfer thermal energy much more efficiently than air, allowing it to rapidly heat and penetrate the items being sterilized.

Principle 2: Pressure as the Enabler

Under normal atmospheric pressure, water boils at 100°C (212°F). This temperature is not sufficient for rapid sterilization.

By increasing the pressure inside a sealed chamber, an autoclave raises the boiling point of water. For example, at a pressure of 15 pounds per square inch (psi) above atmospheric pressure, the temperature of steam reaches 121°C (250°F).

Principle 3: Temperature as the Killing Force

The high temperature achieved is what actually kills microorganisms.

This intense heat destroys essential proteins and enzymes within bacteria, viruses, and spores, a process known as denaturation. This damage is irreversible and renders the microbes non-functional and unable to reproduce.

Principle 4: Time as the Guarantee of Efficacy

Sterilization is not instantaneous. The load must be exposed to the target temperature for a specific duration to ensure all microorganisms, including highly resistant bacterial spores, are eliminated.

A typical cycle for general laboratory equipment is 121°C for at least 20 minutes, but this time can vary depending on the size and type of the load.

How an Autoclave Achieves These Principles

The design of an autoclave is entirely focused on creating and maintaining the conditions dictated by these four principles. Key components from the references, like the pressure chamber, steam generator, and safety valves, all play a role.

The Critical Role of Air Removal

For steam to be effective, it must make direct contact with every surface. Air trapped within the chamber acts as an insulator, creating "cold spots" that will not reach the target sterilization temperature.

Modern autoclaves use a vacuum generator or a series of steam flushes to remove all air from the chamber before the sterilization phase begins. This ensures that the chamber is filled with pure, saturated steam.

Maintaining and Monitoring Conditions

The autoclave's pressure chamber is a robust vessel, typically made of stainless steel, designed to safely contain the high-pressure steam.

A pressure gauge allows for monitoring, while safety valves and whistles are critical safety features that prevent over-pressurization. An electrical heater or external steam source generates the necessary steam.

Common Pitfalls to Avoid

Understanding the core principles helps diagnose why a sterilization cycle might fail. The most common errors directly violate one or more of these foundational concepts.

Incomplete Air Removal

This is the single most common cause of sterilization failure. If air is not fully evacuated, the steam cannot make direct contact with the entire load, leaving some areas unsterilized.

Improper Loading

Packing items too densely within the chamber prevents steam from circulating and penetrating the load. This violates the principle of direct steam contact and creates insulated zones that do not reach the required temperature.

Incorrect Cycle Selection

Different materials require different cycles. A cycle designed for solid glassware will not work for a large flask of liquid media, as it will not provide enough time for the liquid's core to reach the target temperature. Likewise, a liquid cycle's slow exhaust is necessary to prevent boiling over.

Applying These Principles for Successful Sterilization

By keeping the four principles in mind, you can ensure your sterilization process is both effective and reliable.

- If your primary focus is sterilizing solid items (glassware, instruments): Ensure the load is packed loosely to allow for complete steam penetration and that an effective air removal cycle is run.

- If your primary focus is sterilizing liquids (media, buffers): Use a dedicated liquid cycle with a slower temperature ramp-up and exhaust to ensure the core of the liquid reaches temperature without boiling over.

- If your primary focus is validating your process: Use biological indicators containing resistant spores to confirm that the combination of steam, pressure, temperature, and time was sufficient to achieve a complete kill.

Mastering these fundamental principles transforms the autoclave from a simple machine into a precise and dependable scientific instrument.

Summary Table:

| Principle | Role in Sterilization | Key Function |

|---|---|---|

| Steam | Sterilizing Agent | Transfers heat efficiently, penetrates loads |

| Pressure | Enabler | Raises water's boiling point to achieve high temperatures |

| Temperature | Killing Force | Denatures proteins and enzymes in microorganisms |

| Time | Guarantee of Efficacy | Ensures complete destruction of all microbes |

Ensure your lab's sterilization is 100% effective with KINTEK's reliable autoclaves.

As specialists in laboratory equipment, we understand that proper sterilization is non-negotiable for research integrity and safety. KINTEK autoclaves are engineered to perfectly balance the four critical principles of steam, pressure, temperature, and time, guaranteeing complete microbial destruction for all your lab needs—from glassware and instruments to liquid media.

Contact our sterilization experts today to find the ideal autoclave solution for your specific laboratory applications.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What to look for when buying an autoclave? A Guide to Selecting the Right Sterilization Technology

- Which factors contribute to successful sterilization using an autoclave? Master the 3 Keys to Sterility

- How do you sterilize glassware by autoclave? Master the 3-Step Process for Reliable Sterility

- What are the sizes of autoclaves? A Guide to Choosing the Right Capacity for Your Lab

- What are the requirements for an autoclave machine? Achieve Sterile Confidence for Your Lab