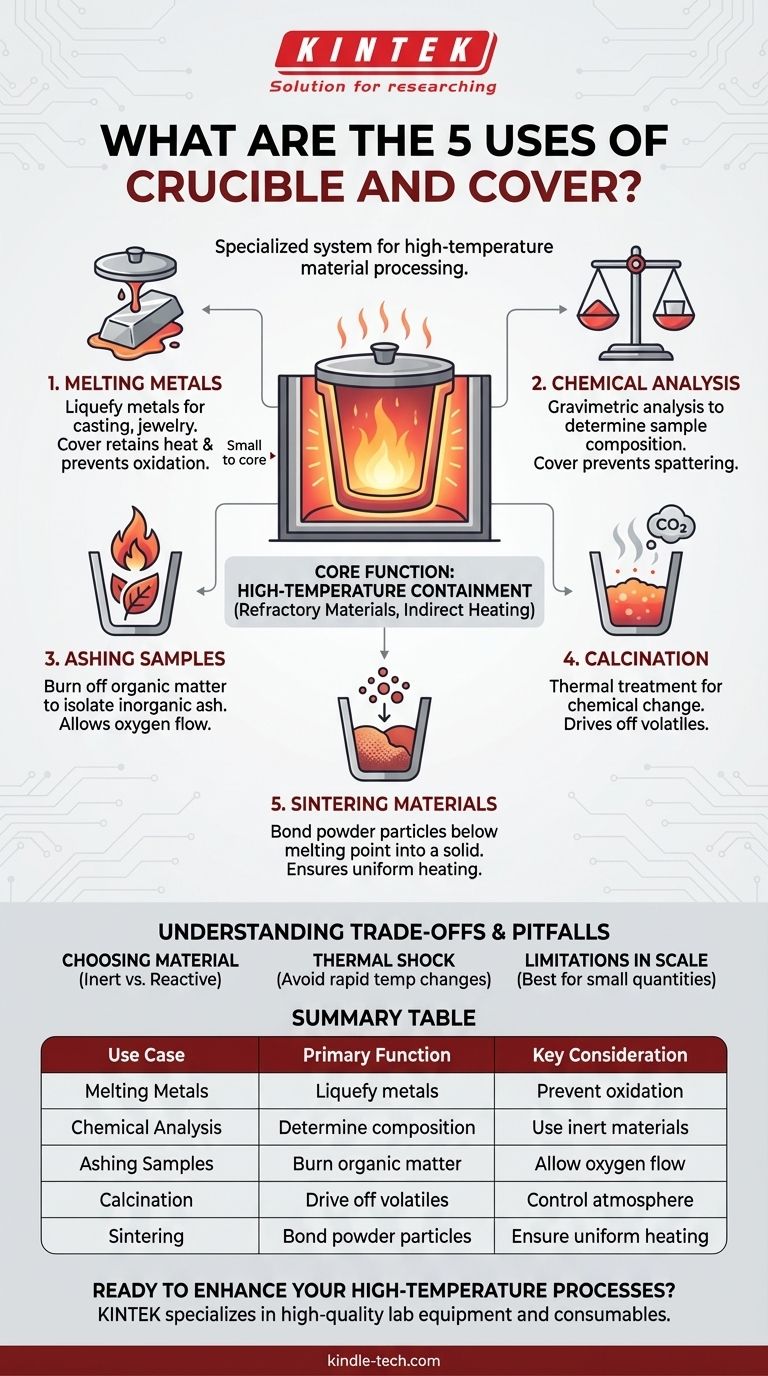

At its core, a crucible and cover is a specialized container system designed to withstand extreme temperatures for processing materials. The five primary uses are melting metals, performing chemical analysis, ashing samples of organic material, carrying out calcination reactions, and sintering powdered materials into a solid mass.

A crucible's fundamental purpose is to act as a stable, non-reactive vessel for containing substances during high-temperature heating, while its cover serves to protect the contents, control the internal atmosphere, and conserve heat.

The Core Function: High-Temperature Containment

A crucible is not just any container. Its defining characteristic is its construction from refractory materials—typically ceramics like porcelain or alumina, graphite, or certain metals like platinum.

What "Refractory" Means

A refractory material is one that can endure extremely high temperatures without melting, deforming, or breaking down. This property is what allows a crucible to be placed directly in a furnace or over a powerful flame.

The Principle of Indirect Heating

In most applications, heat is applied to the outside of the crucible. The crucible's walls then conduct this thermal energy to the material inside, ensuring a controlled and uniform heating process.

A Detailed Look at the Primary Applications

Each use case for a crucible and cover leverages its high-temperature stability for a specific material transformation.

1. Melting Metals

This is the most well-known use, common in metallurgy, foundries, and jewelry making. A metal or alloy is placed in the crucible and heated until it becomes molten.

The cover is crucial here for retaining heat, which speeds up the melting process and saves energy. It also prevents oxidation by limiting the liquid metal's exposure to oxygen in the air.

2. Chemical Analysis

In analytical chemistry, particularly gravimetric analysis, crucibles are indispensable. A sample is placed in a pre-weighed crucible and heated to drive off water or other volatile components.

By weighing the crucible and its contents before and after heating, an analyst can precisely determine the composition of the original sample. The cover prevents spattering and loss of the sample during vigorous heating.

3. Ashing Samples

Ashing is the process of burning away all organic matter from a sample to isolate the inorganic, non-combustible components (the ash). This is common in food science and environmental testing.

A sample is heated to several hundred degrees in a crucible, often with the cover slightly ajar to allow oxygen to enter and facilitate complete combustion.

4. Calcination

Calcination is a specific thermal treatment process used to induce a chemical change. It involves heating a solid material to a high temperature to drive off a specific component.

A classic example is heating limestone (calcium carbonate) in a crucible to produce lime (calcium oxide) by driving off carbon dioxide gas.

5. Sintering Materials

Sintering is a process used in powder metallurgy and ceramics manufacturing. It involves heating a compacted powder to a temperature below its melting point until its particles bond together.

This transforms the loose powder into a solid, coherent object. The crucible contains the powder and ensures it is heated uniformly throughout this delicate process.

Understanding the Trade-offs and Common Pitfalls

While incredibly useful, crucibles require proper handling and selection to be effective and safe.

Choosing the Right Material

The crucible must be chemically inert to the substance it holds. A graphite crucible is excellent for melting non-ferrous metals like aluminum or gold, but a porcelain crucible is better suited for chemical analysis where contamination is a primary concern.

Using the wrong material can lead to the crucible degrading or reacting with your sample, ruining the result.

The Danger of Thermal Shock

Ceramic crucibles are particularly vulnerable to thermal shock. Heating or cooling them too rapidly can cause them to crack or shatter.

It is standard practice to heat crucibles gradually and allow them to cool slowly inside the furnace or on a heat-resistant surface to prevent this from happening.

Limitations in Scale

As noted, crucible-based processes are typically used for smaller quantities, from a few grams in a lab to a few kilograms in a small foundry.

For large-scale industrial production, other types of furnaces are more efficient and practical.

Making the Right Choice for Your Goal

Your application dictates how you should select and use a crucible and cover.

- If your primary focus is metal casting or jewelry: Choose a crucible material (like graphite or silicon carbide) appropriate for your specific metal and always preheat it to drive off moisture before adding your charge.

- If your primary focus is precise chemical analysis: Use a clean, porcelain crucible and ensure you heat it to a constant weight both before and after adding your sample for accurate results.

- If your primary focus is general high-temperature reactions: Always prioritize safety by handling the crucible with proper tongs, being mindful of thermal shock, and ensuring it is placed on a stable, heat-proof surface.

Ultimately, the crucible and cover is a simple yet powerful tool for harnessing heat to transform materials with precision and control.

Summary Table:

| Use Case | Primary Function | Key Consideration |

|---|---|---|

| Melting Metals | Liquefy metals for casting | Prevent oxidation with cover |

| Chemical Analysis | Determine sample composition | Use inert materials like porcelain |

| Ashing Samples | Burn off organic matter | Allow oxygen flow for combustion |

| Calcination | Drive off volatile components | Control atmosphere for reaction |

| Sintering | Bond powder particles | Ensure uniform heating |

Ready to enhance your high-temperature processes? The right crucible is critical for achieving precise results in melting, analysis, and sintering. KINTEK specializes in high-quality lab equipment and consumables, including a wide range of crucibles and covers made from materials like porcelain, alumina, and graphite to suit your specific application—whether you're in metallurgy, chemistry, or materials science.

Our experts can help you select the perfect crucible to ensure safety, prevent contamination, and improve efficiency in your lab. Contact KINTEK today to discuss your needs and get a personalized recommendation!

Visual Guide

Related Products

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

People Also Ask

- How does the choice between graphite and metal-lined crucibles affect molten salt corrosion? Find the Right Research Tool

- Why are corrosion-resistant alloy crucibles required? Ensure Purity in Molten Salt Electrodeposition

- What role do high-temperature ceramic crucibles play in the synthesis of Na2Ni2TeO6 and Na2Zn2TeO6 at 850 Celsius?

- What material is crucible best made of? Match the Material to Your Metal and Process

- What is the best type of crucible? The Answer Depends on Your Application's Needs

- What is the primary function of high-alumina crucibles in pretreatment? Ensure Safe & Pure Phosphate Glass Synthesis

- Why use a lidded crucible and mother powder for LLZTO sintering? Essential Techniques for Lithium Stability

- What are crucibles used for? A Guide to High-Temperature Containers for Melting & Analysis