At its core, electron beam (e-beam) evaporation is a physical vapor deposition (PVD) technique prized for its ability to vaporize materials with extremely high melting points. By using a focused beam of high-energy electrons, it directly heats the source material, achieving temperatures and deposition rates that are often unattainable with simpler thermal methods. This makes it a powerful and versatile tool for creating high-purity, precision thin films.

E-beam evaporation offers superior deposition speed and material versatility, particularly for high-temperature materials. However, its effectiveness is defined by its line-of-sight nature, which is a key advantage for some applications and a significant limitation for others.

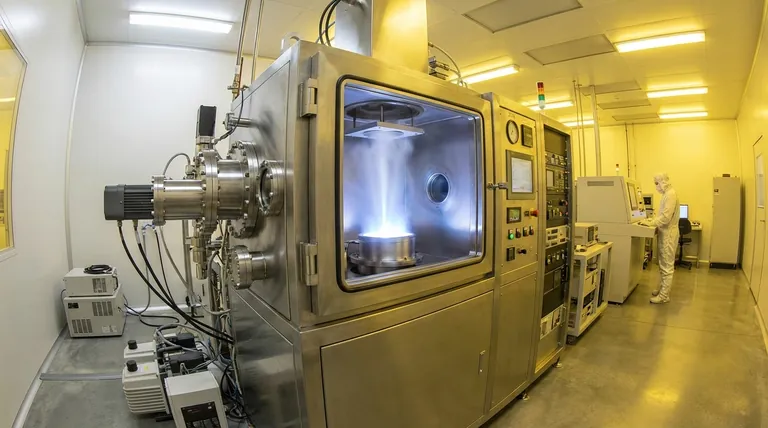

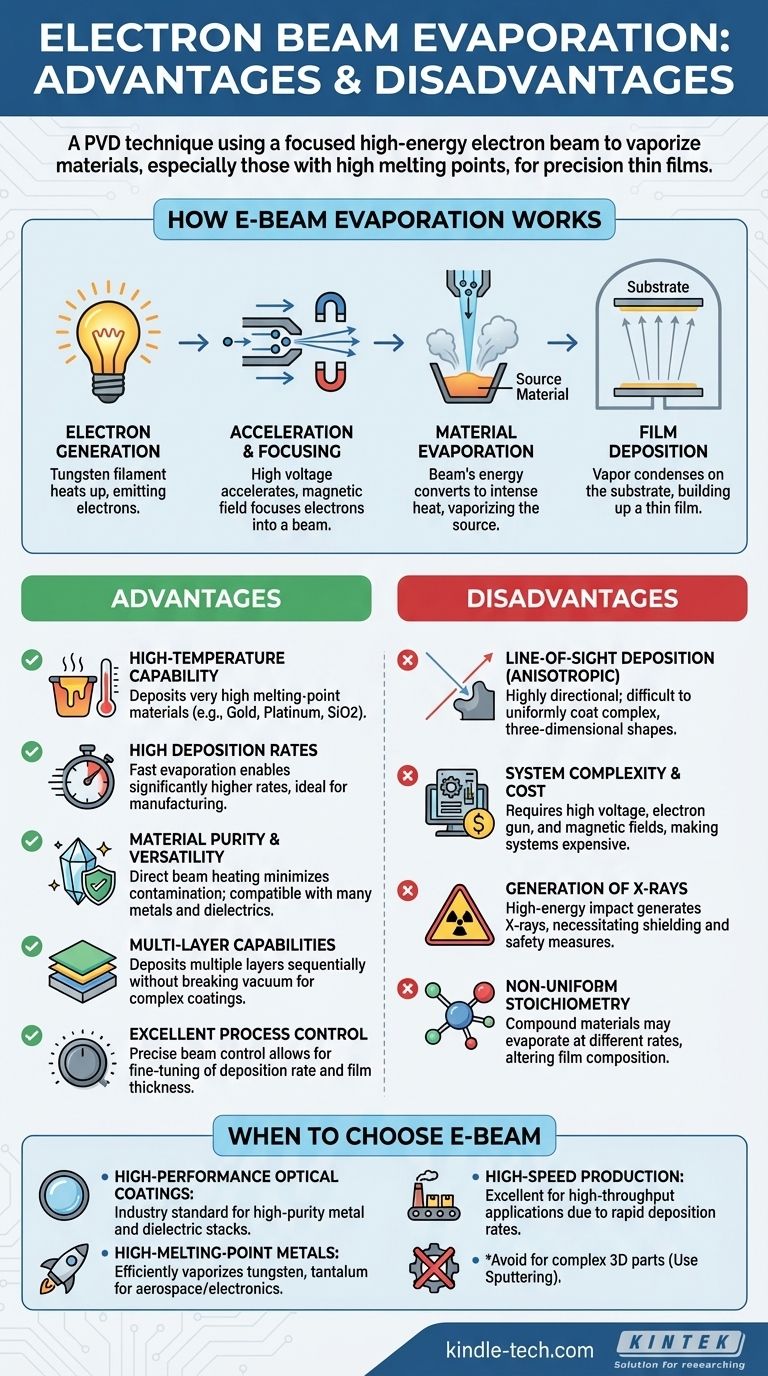

How E-Beam Evaporation Works

Understanding the mechanism of e-beam evaporation is key to appreciating its unique advantages and limitations. The process is a highly controlled transfer of energy.

Step 1: Electron Generation

A current is passed through a tungsten filament, causing it to heat up and emit electrons. This is the source of the "beam."

Step 2: Acceleration and Focusing

A high voltage is applied to accelerate the liberated electrons toward the source material. A powerful magnetic field is then used to precisely guide and focus these electrons into a tight beam, concentrating their energy onto a small spot.

Step 3: Material Evaporation

When the high-energy electron beam strikes the source material held in a crucible, its kinetic energy is instantly converted to thermal energy. This intense, localized heating causes the material to evaporate (or sublimate), creating a vapor cloud within the vacuum chamber.

Step 4: Film Deposition

The vaporized atoms travel in a straight line from the source to the substrate, which is positioned above. Upon arrival, the atoms condense on the cooler substrate surface, gradually building up a thin film.

Key Advantages of E-Beam Evaporation

The unique energy delivery mechanism of e-beam gives it several distinct advantages over other deposition methods.

High-Temperature Capability

The direct energy transfer allows e-beam systems to reach temperatures far exceeding those of standard resistive thermal evaporators. This enables the deposition of materials with very high melting points, such as gold, platinum, and silicon dioxide (SiO2).

High Deposition Rates

Because the energy is so efficiently concentrated on the source material, evaporation happens quickly. E-beam evaporation provides significantly higher deposition rates compared to methods like sputtering or resistive thermal evaporation, which is ideal for manufacturing environments.

Material Purity and Versatility

The electron beam heats only the source material, not the crucible holding it. This minimizes contamination and results in high-purity films. The process is compatible with a wide range of metals and dielectric materials.

Multi-Layer Capabilities

Modern e-beam systems can hold multiple crucibles, each with a different material. This allows for the deposition of multiple thin film layers onto a single substrate in sequence without having to break the vacuum, which is critical for creating complex optical coatings.

Excellent Process Control

The intensity of the electron beam can be precisely controlled, which allows for fine-tuning of the deposition rate and film thickness. This control is crucial for creating repeatable, high-performance films with specific properties.

Understanding the Trade-offs and Limitations

No technology is without its drawbacks. The power and precision of e-beam evaporation introduce specific challenges and limitations.

Line-of-Sight Deposition

The evaporated material travels in a straight line from the source to the substrate. This results in a highly directional, or anisotropic, coating. While this is beneficial for certain applications like "lift-off" patterning, it makes it very difficult to coat complex, three-dimensional shapes uniformly.

System Complexity and Cost

The need for a high-voltage power supply, an electron gun, and powerful magnetic fields makes e-beam systems significantly more complex and expensive than simpler thermal evaporation setups.

Generation of X-rays

The impact of high-energy electrons on the source material can generate X-rays as a byproduct. This requires proper shielding to ensure operator safety and can potentially damage sensitive electronic components or substrates.

Non-Uniform Stoichiometry

When evaporating a compound material (e.g., an oxide), the different elements within the compound may have different vapor pressures. This can lead to the film having a slightly different chemical ratio (stoichiometry) than the source material, which can alter its properties.

When to Choose Electron Beam Evaporation

Selecting the right deposition technique depends entirely on your material requirements and application goals.

- If your primary focus is high-performance optical coatings: E-beam is the industry standard due to its ability to deposit high-purity layers of metals and dielectrics (like SiO2 and TiO2) in complex stacks.

- If your primary focus is depositing refractory or high-melting-point metals: E-beam is one of the few methods that can efficiently vaporize materials like tungsten, tantalum, or platinum for coatings in aerospace or high-temperature electronics.

- If your primary focus is coating complex 3D parts: E-beam is a poor choice due to its line-of-sight nature; a technique like sputtering would provide much better conformal coverage.

- If your primary focus is high-speed, high-volume production: The high deposition rates of e-beam make it an excellent choice for applications where throughput is a critical factor.

Ultimately, electron beam evaporation is a high-performance tool designed for applications where material purity, deposition speed, and the ability to handle challenging materials are non-negotiable.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Temperature Capability | Can vaporize materials with extremely high melting points (e.g., gold, SiO2). | - |

| Deposition Rate | High deposition rates, ideal for manufacturing. | - |

| Material Purity | High-purity films due to minimal contamination. | May alter stoichiometry of compound materials. |

| Coating Uniformity | - | Line-of-sight deposition limits coating of complex 3D shapes. |

| System Complexity | - | More complex and expensive than simpler thermal evaporation. |

| Safety | - | Generates X-rays, requiring shielding and safety measures. |

Ready to elevate your thin film deposition process? Electron beam evaporation is a powerful solution for applications demanding high purity, high melting-point materials, and rapid deposition rates. At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your laboratory's unique needs. Whether you're working on optical coatings, aerospace components, or high-temperature electronics, our expertise ensures you get the right tools for superior results. Contact us today to discuss how our e-beam evaporation solutions can enhance your research and production efficiency!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition