In essence, heat treatment is a powerful metallurgical process used to intentionally alter a material's physical and mechanical properties. By subjecting materials like steel to controlled heating and cooling cycles, you can enhance characteristics such as strength, hardness, and ductility, or relieve internal stresses to improve machinability. However, the specific method chosen introduces critical trade-offs in surface finish, cost, and process complexity.

Heat treatment allows you to unlock a material's peak performance potential. The central challenge is not if you should use it, but which process correctly balances the desired property enhancements against the inherent limitations and costs of the method.

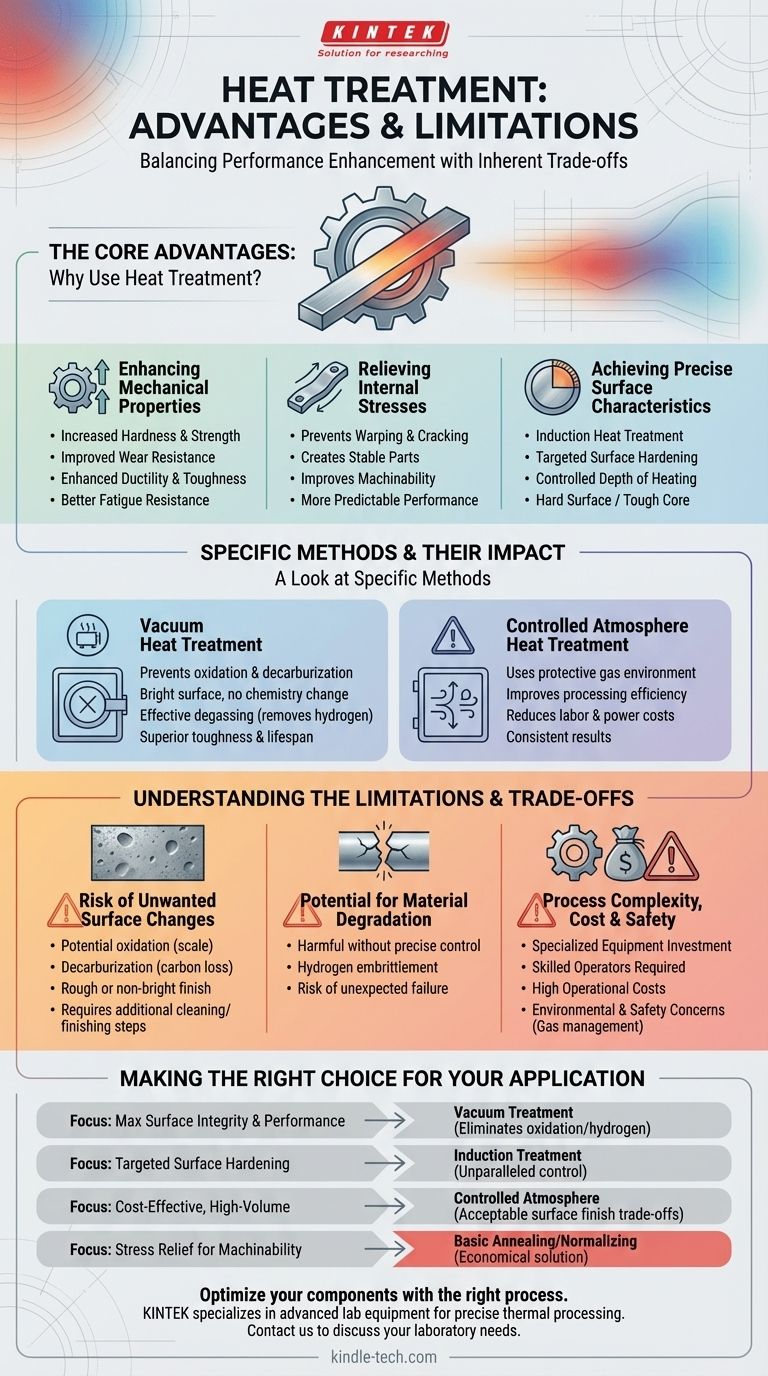

The Core Advantages: Why Use Heat Treatment?

Heat treatment is not a single process but a family of techniques, each designed to achieve a specific engineering goal. While not every component requires it, the benefits are substantial when performance is critical.

Enhancing Mechanical Properties

The most common reason for heat treatment is to improve a material's mechanical performance. This can involve increasing hardness and wear resistance for components subject to abrasion or contact stress.

Conversely, processes can be used to increase ductility and toughness, making a material less brittle and more resistant to fracture under impact.

Relieving Internal Stresses

Manufacturing processes like welding, casting, or hot forming can introduce significant internal stresses within a material.

These stresses can lead to warping, cracking, or premature failure. Heat treatment can relieve these stresses, creating a more stable and predictable part that is far easier to machine accurately.

Achieving Precise Surface Characteristics

Some applications require properties that are only needed on the surface of a part. Processes like induction heat treatment offer remarkable precision.

By adjusting the frequency of the electrical current, you can control the exact depth of heating. This allows you to create a hard, wear-resistant surface while maintaining a softer, tougher core, optimizing the part for its specific function.

A Look at Specific Heat Treatment Methods

The advantages and limitations become clearer when looking at distinct methods. The choice of process directly impacts the final outcome.

Vacuum Heat Treatment

This method is performed in a vacuum, which provides exceptional benefits. It completely prevents oxidation and decarburization, ensuring the part's surface remains bright and its chemistry unchanged.

Vacuum furnaces are also highly effective at degassing, removing trapped elements like hydrogen that can cause brittleness. This results in superior toughness, fatigue resistance, and overall component lifespan.

Controlled Atmosphere Heat treatment

This technique involves using a specific gas environment to protect the part during heating. It offers significant advantages in processing efficiency and can reduce labor costs compared to older methods.

By controlling the atmosphere, you can achieve consistent results with lower consumption of power and auxiliary materials, leading to a more cost-effective production cycle.

Understanding the Limitations and Trade-offs

Despite its benefits, heat treatment is not a universally perfect solution. Understanding the downsides is crucial for making an informed decision.

Risk of Unwanted Surface Changes

While vacuum treatment produces a clean surface, other methods can have the opposite effect. Controlled atmosphere heat treatment, for example, can result in a rough or non-bright surface.

This necessitates additional cleaning or finishing steps, which adds time and cost to the manufacturing process.

Potential for Material Degradation

If the process is not precisely controlled, heat treatment can harm the material. Without a protective atmosphere or vacuum, the surface can oxidize (scale) or decarburize (lose carbon), which degrades its hardness and fatigue life.

Furthermore, certain processes can introduce elements like hydrogen, leading to hydrogen embrittlement and a higher risk of unexpected failure.

Process Complexity and Cost

Advanced heat treatment methods require a significant investment in specialized equipment, such as vacuum furnaces, induction coils, or gas management systems.

These processes also demand skilled operators to manage the complex variables, adding to the overall operational cost. The benefits of enhanced properties must justify this added expense.

Environmental and Safety Concerns

Some methods, particularly controlled atmosphere treatments, involve complex challenges related to gas usage, storage, and recovery.

Managing these industrial gases safely and in an environmentally responsible manner adds another layer of operational complexity and regulatory compliance.

Making the Right Choice for Your Application

Selecting the correct heat treatment process requires aligning the technique's strengths with your primary engineering goal.

- If your primary focus is maximum surface integrity and mechanical performance: Vacuum heat treatment is the superior choice, as it eliminates oxidation and hydrogen embrittlement.

- If your primary focus is targeted surface hardening with high precision: Induction heat treatment offers unparalleled control over the depth and location of hardening.

- If your primary focus is cost-effective, high-volume production: Controlled atmosphere treatment can be a good option, provided you can accept the trade-offs in surface finish.

- If your primary focus is simply relieving stress for better machinability: A basic annealing or normalizing process is often sufficient and more economical than advanced methods.

Ultimately, understanding the advantages and limitations of each heat treatment process empowers you to make smarter, more effective engineering decisions.

Summary Table:

| Advantage | Limitation |

|---|---|

| Enhances hardness, strength, and wear resistance | Risk of surface oxidation/decarburization |

| Relieves internal stresses for stability | Potential for hydrogen embrittlement |

| Precise surface hardening (e.g., induction) | Requires specialized, costly equipment |

| Clean, bright surfaces with vacuum treatment | Added process complexity and operational cost |

| Improves fatigue resistance and part lifespan | Environmental/safety concerns with gas usage |

Optimize your components with the right heat treatment process. The choice between vacuum, induction, and controlled atmosphere methods is critical for balancing performance, cost, and surface quality. KINTEK specializes in advanced lab equipment and consumables for precise thermal processing. Our expertise ensures you achieve the desired material properties—whether it's maximum hardness, stress relief, or superior surface integrity. Contact us today to discuss your specific laboratory needs and discover how our solutions can enhance your results. [#ContactForm]

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is environmental control within a vacuum furnace important for diffusion bonding? Master Titanium Alloy Laminates

- What does a vacuum furnace do? Achieve High-Purity Heat Treatment for Superior Components

- What are the uses of vacuum furnace? Achieve Unmatched Material Purity and Performance

- What are vacuum furnace parts? A Guide to the Core Systems for Precision Heat Treatment

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost