At its core, a crucible furnace provides a combination of operational simplicity, material versatility, and cost-effectiveness. Its primary advantages are its ability to melt a wide range of materials from metals to glass, its compact size suitable for small-scale work, its precise temperature control, and its relatively low initial investment and operating costs.

A crucible furnace excels in applications where flexibility and control over small-to-medium batches are more critical than mass production. It is the definitive choice for labs, artists, and specialized workshops, but its value is defined by understanding its inherent trade-offs between batch size and material purity.

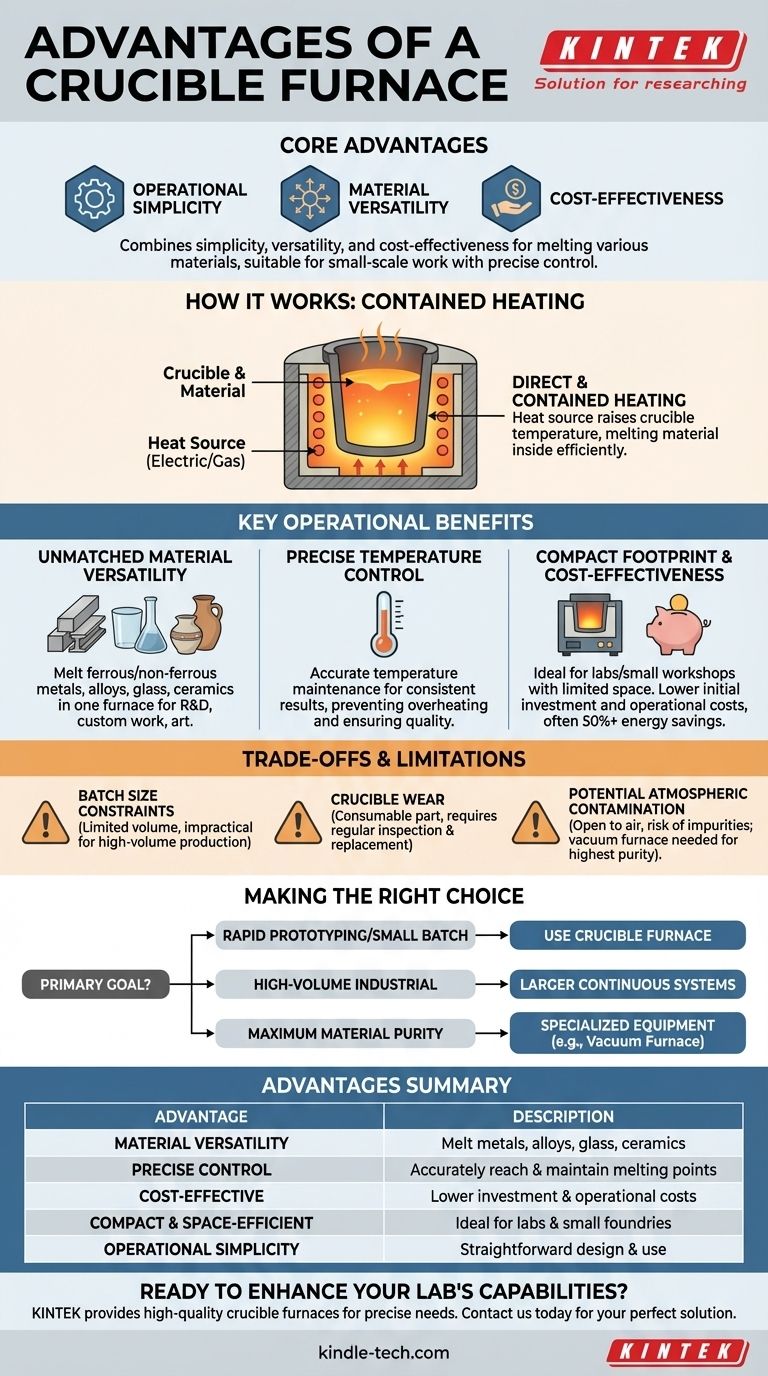

How a Crucible Furnace Works

To understand its advantages, you must first understand its fundamental design. A crucible furnace operates on a straightforward principle of contained heating.

The Core Components: Crucible and Heat Source

A crucible furnace has two main parts. The crucible is a container made from a material that can withstand extreme temperatures, such as graphite or silicon carbide, which holds the material to be melted.

The second part is the heat source, which surrounds the crucible. This is typically powered by electric resistance elements or a gas burner.

The Heating Process: Direct and Contained

The heat source raises the temperature of the crucible through direct transfer. The crucible, in turn, heats the material inside until it reaches its melting point.

This simple, contained system is the source of many of the furnace's key benefits, as it allows for efficient heat transfer and a relatively controlled environment without complex machinery.

Key Operational Benefits Breakdown

The simple design of a crucible furnace translates directly into several powerful operational advantages.

Unmatched Material Versatility

Because the material is melted inside an inert container, a single furnace can be used to melt a vast range of materials. This includes ferrous and non-ferrous metals, precious metals, alloys, glass, and even some ceramics.

This flexibility makes it an invaluable tool for research and development, custom fabrication, and artistic applications where material needs can change from one day to the next.

Precise Temperature Control

Modern crucible furnaces, especially electric models, offer excellent temperature control. This allows operators to precisely hit the specific melting point of a given alloy without overheating it, which is critical for maintaining the metal's desired properties.

This level of control ensures consistency and quality in the final cast product.

Compact Footprint and Cost-Effectiveness

Compared to industrial-scale induction or arc furnaces, crucible furnaces are significantly smaller and more affordable. Their compact size makes them a perfect fit for laboratories, small foundries, and workshops with limited space.

Furthermore, their operational efficiency, often saving over 50% in energy compared to older technologies, and straightforward maintenance keep running costs low.

Understanding the Trade-offs and Limitations

No tool is perfect for every job. The advantages of a crucible furnace come with clear, definable limitations that are crucial to understand.

Inherent Batch Size Constraints

The most significant limitation is scale. The volume of a crucible furnace is defined by the size of the crucible itself. This makes it impractical for high-volume industrial production where tons of metal must be melted continuously.

Crucible Wear and Replacement

The crucible is a consumable component. It is subjected to extreme thermal stress and chemical interaction with molten materials, causing it to degrade over time.

This wear requires regular inspection and eventual replacement, which is an ongoing operational cost that must be factored into any project.

Potential for Atmospheric Contamination

While some designs are very clean, a standard crucible furnace is open to the atmosphere. This means reactive metals like aluminum or titanium can be exposed to oxygen and other gases during melting, which can create impurities (oxides) in the final product.

For applications requiring the absolute highest purity, a specialized system like a vacuum furnace, which removes the atmosphere entirely, is a more appropriate choice.

Making the Right Choice for Your Goal

Selecting a furnace requires aligning its capabilities with your primary objective.

- If your primary focus is rapid prototyping or small-batch artistic work: The crucible furnace's blend of versatility, cost-effectiveness, and precise control makes it the ideal choice.

- If your primary focus is high-volume industrial melting: You will need to look beyond a crucible furnace to larger, continuous-process systems designed for mass production.

- If your primary focus is achieving maximum material purity: You should consider specialized equipment like vacuum or induction furnaces to eliminate the risk of atmospheric contamination.

By understanding its core strengths and limitations, you can leverage the crucible furnace as a powerful and efficient tool for your specific application.

Summary Table:

| Advantage | Description |

|---|---|

| Material Versatility | Melt a wide range of metals, alloys, glass, and ceramics in a single furnace. |

| Precise Temperature Control | Accurately reach and maintain specific melting points for consistent results. |

| Cost-Effectiveness | Lower initial investment and operational costs compared to larger industrial furnaces. |

| Compact & Space-Efficient | Ideal for laboratories, small foundries, and workshops with limited space. |

| Operational Simplicity | Straightforward design allows for easy use and maintenance. |

Ready to enhance your lab's capabilities with a crucible furnace?

KINTEK specializes in providing high-quality lab equipment, including crucible furnaces, to meet the precise needs of laboratories, workshops, and research facilities. Our furnaces deliver the material versatility, precise control, and cost-efficiency your projects demand.

Contact us today to find the perfect crucible furnace solution for your application!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control