In essence, Physical Vapor Deposition (PVD) is an advanced coating process that offers an unmatched combination of performance, precision, and versatility. It is a vacuum deposition method used to produce extremely thin, high-performance films on a wide variety of substrates, enhancing their durability, functionality, and appearance in ways that other coating methods cannot.

PVD's primary advantage is its ability to deposit highly durable, functional, and aesthetically pleasing thin-film coatings onto an extensive range of materials—including those sensitive to heat—with exceptional precision and minimal environmental impact.

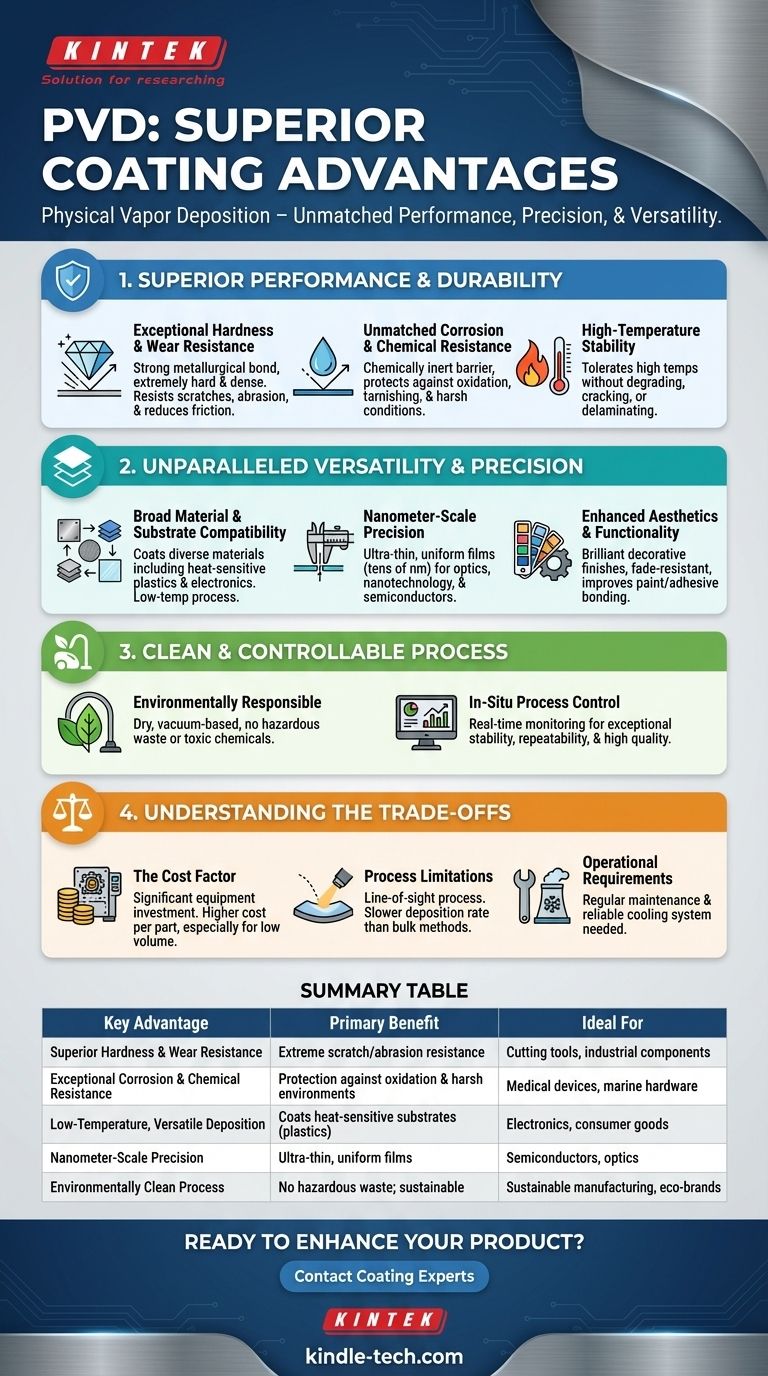

Superior Performance and Durability

A core reason for selecting PVD is the significant enhancement in a product's physical properties. The process creates a strong metallurgical bond between the coating and the substrate, resulting in a finish that is part of the object itself, not just a superficial layer.

Exceptional Hardness and Wear Resistance

PVD coatings are extremely hard and dense, providing a powerful barrier against damage. This significantly increases a product's resistance to scratches, abrasion, and general wear.

The coatings also reduce the coefficient of friction, creating a lubricious surface that enhances performance and longevity in moving parts.

Unmatched Corrosion and Chemical Resistance

The deposited film acts as a chemically inert barrier, protecting the underlying substrate from oxidation, tarnishing, and corrosion. This makes PVD ideal for components exposed to harsh environmental or chemical conditions.

High-Temperature Stability

PVD coatings are capable of tolerating high temperatures without degrading, cracking, or delaminating. This stability is critical for applications in high-performance engines, cutting tools, and aerospace components.

Unparalleled Versatility and Precision

PVD is not a single process but a family of techniques, giving it incredible flexibility. It goes far beyond what traditional methods like electroplating can achieve.

Broad Material and Substrate Compatibility

The process can deposit a vast array of materials, including pure metals, alloys, carbides, nitrides, and oxides.

Crucially, PVD is a low-temperature process. This allows it to coat substrates that cannot withstand the high heat of other methods, such as plastics, sensitive electronics, and bio-compatible materials.

Nanometer-Scale Precision

PVD enables the deposition of films that are exceptionally thin—often just a few tens of nanometers—while maintaining perfect uniformity and dimensional accuracy.

This precision is essential for modern applications in nanotechnology, optics (e.g., anti-reflective coatings), photovoltaics, and semiconductors.

Enhanced Aesthetics and Functionality

Beyond protection, PVD provides brilliant decorative finishes in a wide spectrum of colors that are resistant to chipping and fading. It can also improve a surface for better paint or adhesive bonding.

A Clean and Controllable Process

The operational characteristics of PVD provide significant advantages in both quality control and environmental responsibility, setting it apart from older, chemical-based processes.

Environmentally Responsible

PVD is a dry, vacuum-based process that produces no hazardous waste and uses no toxic chemicals. This clean operation eliminates the environmental and safety risks associated with methods like chemical plating.

In-Situ Process Control

Modern PVD systems allow for real-time, in-situ monitoring and control. This ensures exceptional stability, repeatability, and feedback during deposition, leading to consistently high-quality outcomes.

Understanding the Trade-offs

While PVD offers powerful advantages, it is essential to recognize its limitations to determine if it is the right solution for your application.

The Cost Factor

PVD equipment represents a significant capital investment. The complexity of the process can make it more expensive per part than some traditional coating methods, especially for low-volume production.

Process Limitations

PVD is a line-of-sight process, which can make it challenging to coat complex internal geometries uniformly. It also tends to have a slower deposition rate or yield compared to bulk processes like electroplating.

Operational Requirements

The vacuum chambers and associated equipment require regular maintenance to ensure consistent performance. A reliable and often substantial cooling system is also a critical operational requirement.

Making the Right Choice for Your Goal

PVD is a superior choice when performance and precision are non-negotiable. To decide if it fits your project, consider your primary objective.

- If your primary focus is maximizing product lifespan and durability: PVD provides unparalleled resistance to wear, corrosion, and heat, making it the definitive choice for high-performance parts.

- If your primary focus is coating sensitive or non-traditional materials: PVD's low-temperature application makes it one of the only viable methods for coating plastics, electronics, or biomedical substrates without causing damage.

- If your primary focus is achieving specific aesthetic or optical properties: PVD offers precise control over color, finish, and film thickness, creating durable, brilliant aesthetics or exact optical functions that other methods cannot replicate.

- If your primary focus is environmental sustainability and process control: PVD is an inherently clean and highly controllable process, eliminating hazardous waste and ensuring repeatable, high-quality results.

Ultimately, choosing PVD is an investment in superior performance, precision, and longevity for your product.

Summary Table:

| Key Advantage | Primary Benefit | Ideal For |

|---|---|---|

| Superior Hardness & Wear Resistance | Extreme scratch/abrasion resistance & reduced friction | Cutting tools, industrial components, moving parts |

| Exceptional Corrosion & Chemical Resistance | Protection against oxidation, tarnishing, and harsh environments | Medical devices, marine hardware, chemical processing parts |

| Low-Temperature, Versatile Deposition | Coats heat-sensitive substrates like plastics & electronics | Electronics, consumer goods, biomedical components |

| Nanometer-Scale Precision | Ultra-thin, uniform films for exacting applications | Semiconductors, optics, nanotechnology |

| Environmentally Clean Process | No hazardous waste; a dry, vacuum-based method | Sustainable manufacturing, eco-conscious brands |

Ready to enhance your product's performance and lifespan with PVD coating?

KINTEK specializes in advanced lab equipment and coating solutions, including PVD systems tailored to your specific needs. Whether you're developing high-performance industrial components, sensitive electronic devices, or durable consumer products, our expertise ensures you achieve superior durability, precision, and eco-friendly results.

Contact our coating experts today to discuss how PVD can solve your material challenges and add value to your manufacturing process!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition