For preserving a sample's fundamental integrity, a laboratory freeze dryer, or lyophilizer, is unequivocally superior to conventional drying methods like ovens. While heat-based drying forcibly evaporates water and degrades the material, freeze-drying gently removes water via sublimation, perfectly preserving the sample's original structure, chemical composition, and biological activity. This makes it the gold standard for sensitive biologicals, pharmaceuticals, and high-value foods.

The decision between freeze-drying and conventional drying is a strategic choice between two different goals: maximum quality versus maximum speed. Freeze-drying prioritizes the complete preservation of the material, while conventional methods prioritize the rapid removal of water, often at the cost of the sample's integrity.

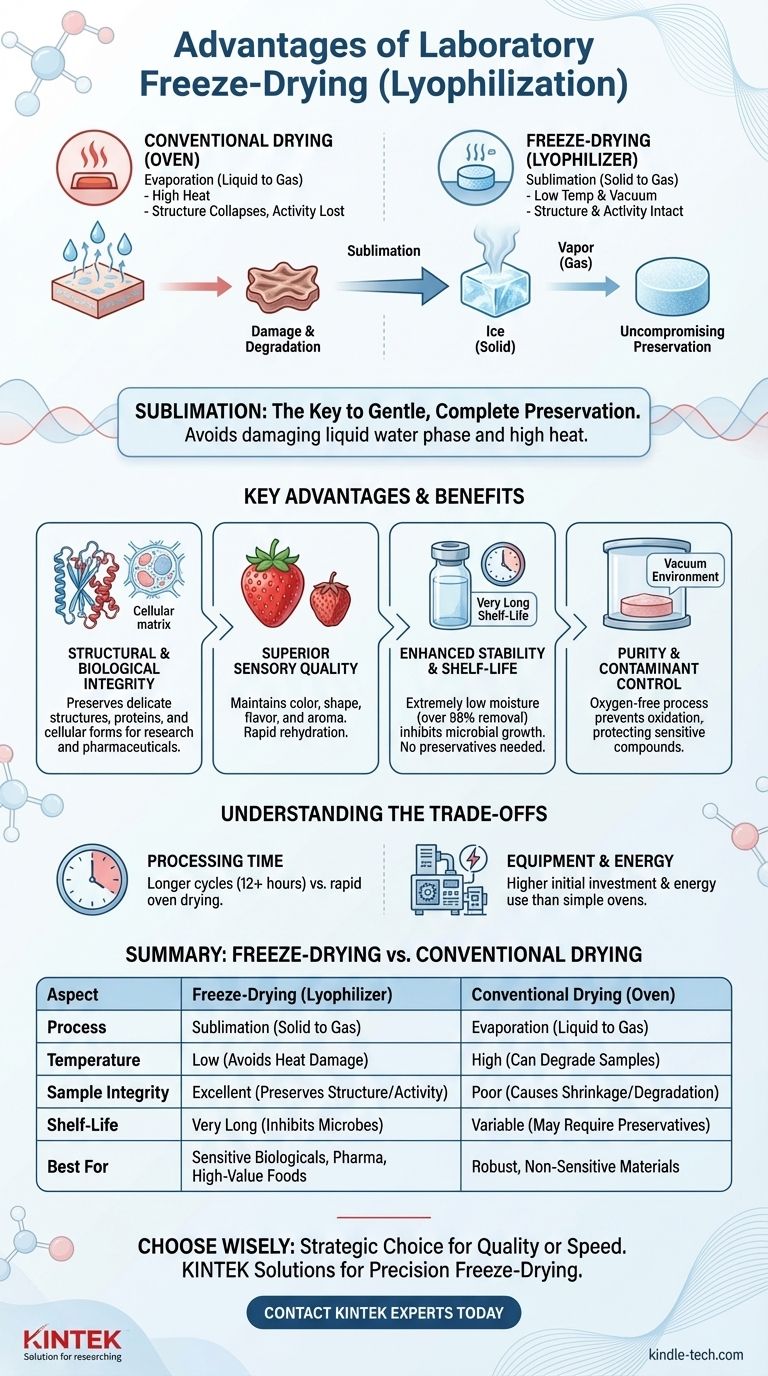

The Core Principle: Sublimation vs. Evaporation

The distinct advantages of freeze-drying stem from one fundamental difference in physics: how water is removed from the sample.

How Conventional Drying Works (and Causes Damage)

Conventional ovens and vacuum ovens use heat to give water molecules enough energy to turn into steam and evaporate.

This process is aggressive. The high temperatures can denature proteins, destroy vitamins, and alter chemical compounds. Furthermore, as liquid water moves to the surface to evaporate, it creates surface tension that collapses the material's internal structure, causing shrinkage, toughness, and irreversible damage.

How Freeze-Drying Works (The Preservation Advantage)

Freeze-drying, or lyophilization, is a three-step process that completely avoids the damaging liquid water phase.

- Freezing: The material is frozen solid, locking its structure and all its components in place.

- Primary Drying (Sublimation): The frozen sample is placed under a deep vacuum. This allows the ice to turn directly into water vapor without ever melting—a process called sublimation.

- Secondary Drying: A slight temperature increase removes any remaining, unfrozen water molecules, resulting in a final product with extremely low moisture content.

By removing water as a gas from a solid, the original structure is left behind perfectly intact, like a flawless skeleton.

Key Advantages of Laboratory Freeze-Drying

This gentle process of sublimation delivers benefits that no other drying method can match.

Unmatched Structural and Biological Preservation

Because it avoids high heat and the destructive forces of liquid water, freeze-drying is the only method that can reliably preserve delicate structures.

This is critical for pharmaceuticals like vaccines and antibodies, where the protein's shape is directly tied to its function. It is also essential for preserving the cellular structure of scientific specimens for microscopy.

Superior Sensory and Aesthetic Quality

For food products, freeze-drying maintains the original color, shape, flavor, and aroma.

The resulting porous structure allows for rapid rehydration. A freeze-dried strawberry, for example, looks and tastes almost identical to a fresh one once rehydrated, whereas an oven-dried strawberry becomes a shrunken, leathery version of its former self.

Enhanced Stability and Long-Term Shelf-Life

Freeze-drying can remove over 98% of a sample's water content without using high heat.

This extremely low moisture level dramatically inhibits microbial growth and oxidative reactions, giving products an exceptionally long shelf-life at room temperature without the need for preservatives.

Purity and Contaminant Control

The process occurs in a sealed, oxygen-free vacuum environment. This prevents oxidation, which is a major cause of degradation for sensitive fats, oils, and pigments. This is a level of protection that a conventional oven, which circulates hot air, cannot offer.

Understanding the Trade-offs

While its results are superior, freeze-drying is not the optimal solution for every scenario. Understanding its limitations is key to making an informed decision.

Processing Time: Quality Requires Patience

True lyophilization is a slow, deliberate process. A typical cycle can take anywhere from 12 hours to several days to complete, depending on the sample size and type. In contrast, a hot-air oven can dry a simple sample in a few hours.

Equipment Cost and Energy Use

Laboratory freeze dryers are complex, precision instruments involving refrigeration systems and powerful vacuum pumps. They represent a significantly higher initial investment than a simple lab oven.

While some modern vacuum systems can be energy-efficient, a full, deep-freeze lyophilization cycle is generally an energy-intensive process compared to simple oven heating.

Solvent and Material Compatibility

Freeze-drying is designed for water-based (aqueous) samples. While possible with certain organic solvents, it requires specialized equipment and careful protocol development. Additionally, materials that do not freeze well or contain high concentrations of sugar or salt can present challenges.

Making the Right Choice for Your Goal

The best drying method depends entirely on the value of your sample and your desired outcome.

- If your primary focus is preserving biological activity, delicate structure, or sensory qualities: A laboratory freeze dryer (lyophilizer) is the only suitable choice.

- If your primary focus is the rapid removal of water from robust, non-sensitive materials: A conventional oven or a vacuum oven is a far more time- and cost-effective solution.

- If your primary focus is removing trace solvents from a heat-sensitive chemical compound: A low-temperature vacuum oven offers a good balance of speed and protection against thermal degradation.

Ultimately, choosing the right drying technology is an investment in the quality of your final result.

Summary Table:

| Aspect | Freeze-Drying (Lyophilizer) | Conventional Drying (Oven) |

|---|---|---|

| Process | Sublimation (solid to gas) | Evaporation (liquid to gas) |

| Temperature | Low (avoids heat damage) | High (can degrade samples) |

| Sample Integrity | Excellent (preserves structure/activity) | Poor (causes shrinkage/degradation) |

| Shelf-Life | Very Long (low moisture inhibits microbes) | Variable (may require preservatives) |

| Best For | Sensitive biologicals, pharmaceuticals, high-value foods | Robust, non-sensitive materials |

Ready to Preserve Your Most Valuable Samples with Uncompromising Quality?

Choosing the right drying technology is an investment in your results. At KINTEK, we specialize in providing precision laboratory freeze dryers (lyophilizers) designed to meet the exacting demands of pharmaceutical, biotech, and food science laboratories. Our equipment ensures the complete preservation of your sample's structural integrity, biological activity, and sensory qualities.

Don't compromise on quality. Contact our experts today to discuss how a KINTEK freeze dryer can enhance your research, improve product stability, and deliver superior long-term outcomes for your sensitive materials.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What is the function of Freeze-thaw Equipment in Au-(PNiPAAm/PVA) hydrogel? Achieve High-Speed Photothermal Actuation

- Why is a laboratory vacuum freeze dryer essential for plant extracts? Preserve Bioactivity & Structure

- Why is a freeze dryer preferred for drying nickel nanoparticle precursors? Prevent Hard Agglomeration Now

- What role does a laboratory freeze dryer play in the synthesis of graphene-based electrocatalysts? Preserve 3D Structures

- Why is a freeze dryer preferred over thermal drying for Fe-ZTA cermets? Ensure Pure, Homogeneous Slurry Processing