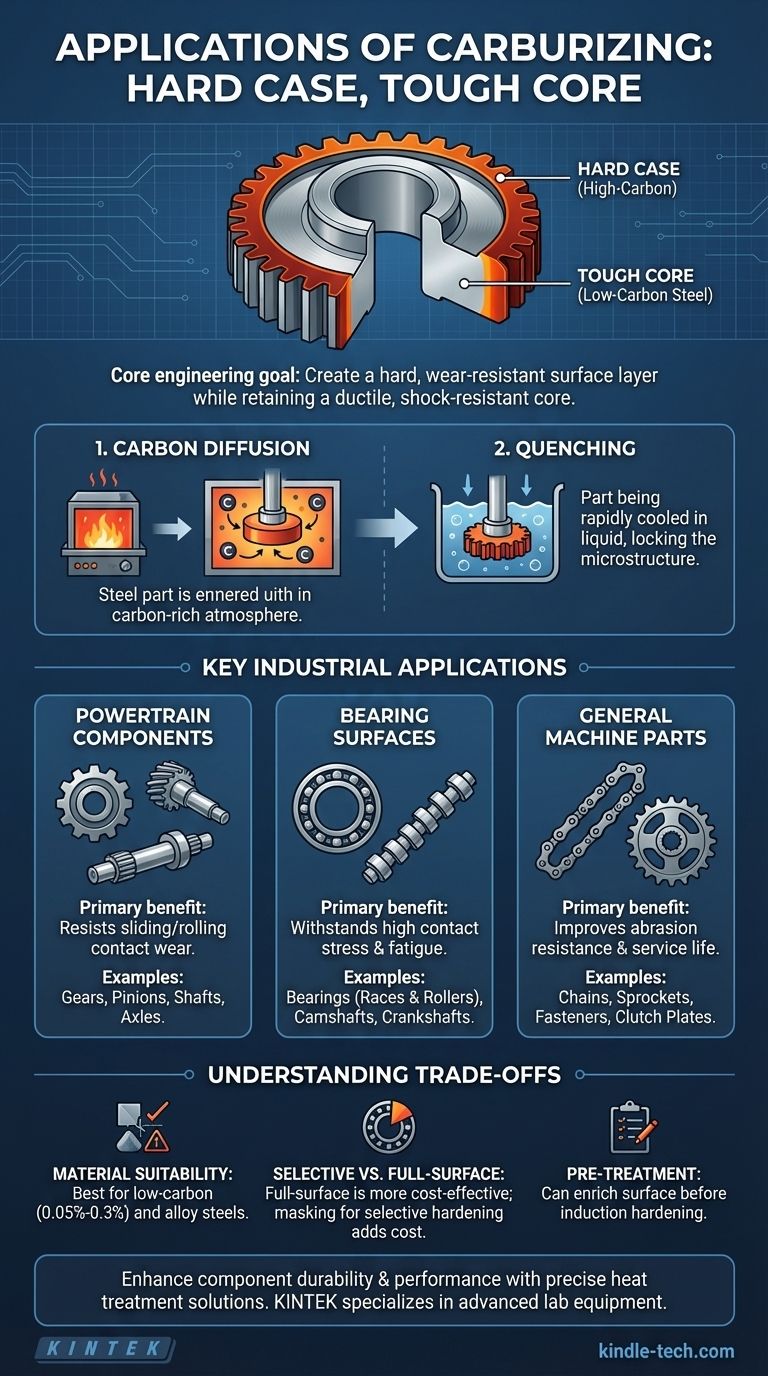

At its core, carburizing is a case-hardening process used to impart a hard, wear-resistant surface layer onto components made from tough, low-carbon steel. This technique is predominantly applied to parts that must withstand high surface pressure and friction while retaining a ductile, shock-resistant core. Common examples include gears, bearings, camshafts, and transmission shafts.

The primary application of carburizing is to create a composite-like component from a single piece of low-carbon steel: a hard, high-carbon "case" for wear resistance on the outside, and a soft, low-carbon "core" for toughness and ductility on the inside.

The Engineering Goal: A Hard Case and a Tough Core

The value of carburizing comes from its ability to create two distinct material properties within a single part, something that is critical for demanding mechanical applications.

How It Achieves This Duality

Carburizing involves heating a low-carbon steel part in a carbon-rich atmosphere. Carbon atoms diffuse into the surface of the steel, significantly increasing the carbon content of the outer layer.

After this diffusion stage, the part is quenched (rapidly cooled). This final step locks the new carbon-rich microstructure into place, creating a very hard surface layer known as the "case," while the untouched interior remains the "core."

The Resulting Advantage

The final component has a hard case that can resist wear, abrasion, and surface fatigue. Simultaneously, the tough core remains ductile and able to absorb shock and impact loads without fracturing.

Key Industrial Applications

This unique dual-property nature makes carburizing essential for manufacturing critical components across various industries, especially in automotive and aerospace.

High-Wear Powertrain Components

Components that transmit power through direct metal-to-metal contact rely heavily on carburizing. The process provides the necessary surface durability to prevent premature failure from friction.

Examples include:

- Gears and Pinions: Resist the constant sliding and rolling contact of gear teeth.

- Shafts and Axles: Withstand torsional stress while resisting wear at bearing and seal contact points.

High-Impact Bearing Surfaces

Parts subjected to high contact stress and rolling friction are ideal candidates for carburizing. The hard case prevents surface indentation and fatigue.

Examples include:

- Bearings (Races and Rollers): Endure immense, repetitive loads without deforming.

- Camshafts and Crankshafts: Resist wear from lifters, followers, and connecting rods.

General Machine Components

Carburizing is also used for a wide range of other machine parts where surface durability is a primary concern.

Examples include:

- Chains and Sprockets: Resist abrasion and friction.

- Clutch Plates and Fasteners: Improve fatigue life and wear characteristics.

Understanding the Trade-offs

While powerful, carburizing is not a universal solution. Its application is governed by specific material and design constraints.

Material Suitability is Not Universal

Carburizing is specifically designed for low-carbon steels and alloy steels, typically with a carbon content between 0.05% and 0.3%. It is ineffective on medium or high-carbon steels, which already have sufficient carbon for through-hardening.

Selective vs. Full-Surface Hardening

The process is most cost-effective when hardening the entire surface of a component. While specific areas can be masked with a "stop-off" paint to prevent carbon diffusion, this adds significant labor and cost to the process.

A Pre-Treatment Step

In some applications, carburizing is not the final step. It can be used to enrich a part's surface with carbon before a more localized hardening process, such as induction hardening, is performed.

Making the Right Choice for Your Application

Selecting a heat treatment process requires matching the method to the engineering goal.

- If your primary focus is exceptional wear and fatigue resistance on a shock-loaded part: Carburizing is an ideal choice for creating the necessary hard case and tough core in low-carbon steel components like gears.

- If your primary focus is cost-effective hardening of high-volume parts: Carburizing is highly automatable and well-understood, making it an excellent option for treating entire batches of components.

- If your primary focus is highly selective or localized hardening: Consider if carburizing the entire surface is acceptable; otherwise, masking can be costly, and alternative methods may be more efficient.

Understanding the principles of carburizing allows you to design and manufacture components with superior longevity and performance.

Summary Table:

| Application Category | Key Examples | Primary Benefit |

|---|---|---|

| Powertrain Components | Gears, Pinions, Axles | Resists sliding/rolling contact wear |

| Bearing Surfaces | Bearings, Camshafts, Crankshafts | Withstands high contact stress & fatigue |

| General Machine Parts | Chains, Sprockets, Fasteners | Improves abrasion resistance & service life |

Need to enhance the durability and performance of your components?

At KINTEK, we specialize in providing the advanced lab equipment and consumables necessary for precise heat treatment processes like carburizing. Whether you are developing gears, bearings, or other critical parts, our solutions help you achieve the perfect balance of a hard, wear-resistant case and a tough, ductile core.

Let's discuss how we can support your laboratory's needs. Contact our experts today to find the right equipment for your application!

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- How do you make an inert atmosphere? Master Safe, Pure Processes with Inerting

- Can nitrogen be used for brazing? Key Conditions and Applications Explained

- How does an atmosphere furnace facilitate the post-treatment of nickel-plated carbon fibers? Ensure Peak Bonding

- What is the role of an atmosphere-controlled tube furnace in Cu-Mo sintering? Achieve High-Purity Densification

- What provides an inert atmosphere? Achieve Safety and Purity with Nitrogen, Argon, or CO2