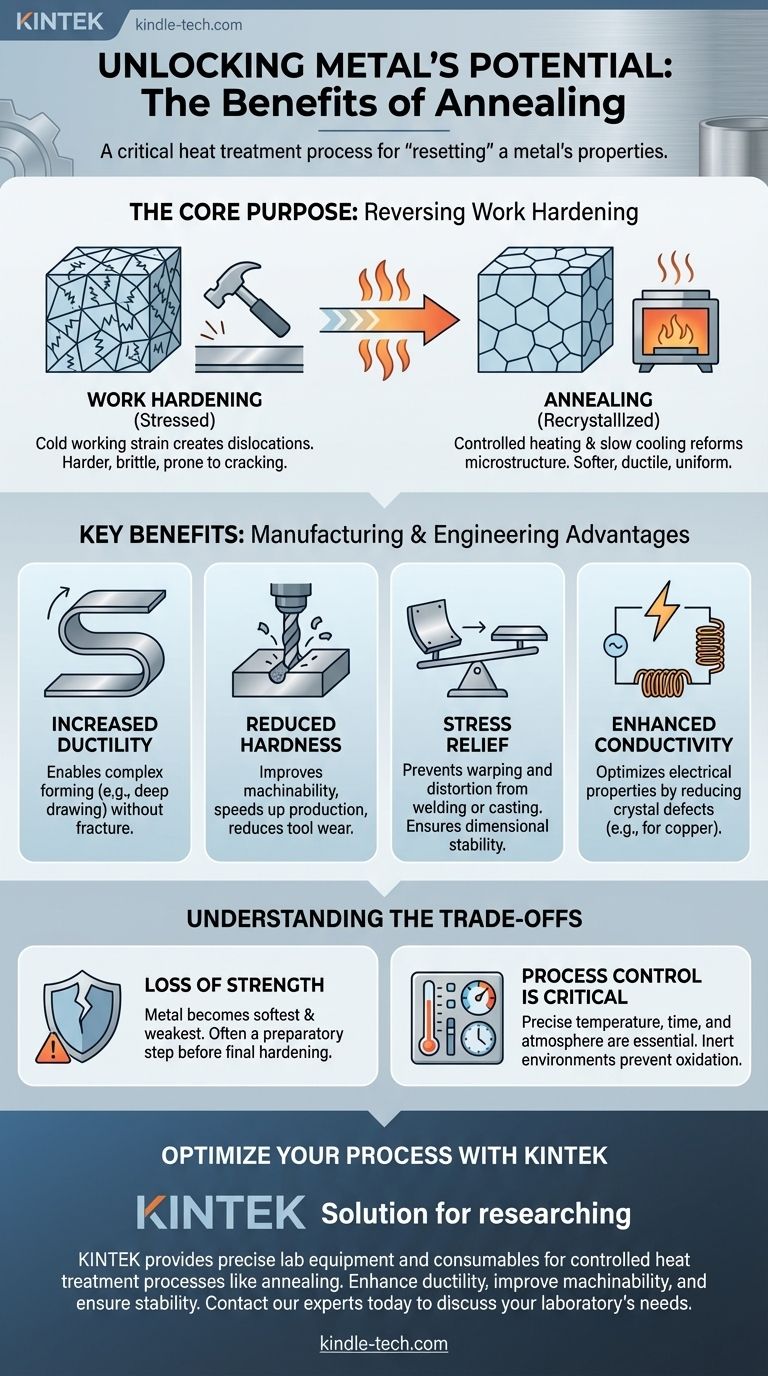

The primary benefits of annealing metal are to reduce its hardness, increase its ductility, and relieve internal stresses. This heat treatment process fundamentally alters the metal's internal microstructure, making it significantly easier to shape, machine, or form without fracturing. It also refines the grain structure, which can improve electrical properties.

Annealing should be understood not just as a softening process, but as a critical tool for "resetting" a metal's properties. It prepares the material for subsequent manufacturing steps by making its behavior more predictable and cooperative.

The Core Purpose of Annealing: Reversing Work Hardening

To understand the benefits of annealing, we must first understand the problem it solves: work hardening.

What is Work Hardening?

When a metal is bent, hammered, or otherwise deformed at room temperature (a process called cold working), its internal crystal structure becomes strained and filled with defects known as dislocations.

This process, called work hardening, makes the metal stronger and harder, but also significantly more brittle and difficult to work with. Continued cold working will eventually lead to cracking.

How Annealing Works

Annealing reverses this process through a controlled cycle of heating and cooling.

The metal is heated to a specific annealing temperature, where its crystalline structure becomes more fluid, though the metal remains solid. It is held at this temperature (a step called soaking) to allow the microstructure to reform.

Finally, it is cooled at a very slow, controlled rate. This slow cooling is crucial for producing a soft, uniform, and stress-free internal structure.

The Microstructural Change

At the annealing temperature, new, strain-free crystals form and grow within the metal in a process called recrystallization.

This process effectively repairs the defects and eliminates the dislocations caused by work hardening, resulting in a more ductile and uniform grain structure.

Key Benefits in Manufacturing and Engineering

The microstructural changes from annealing provide several distinct advantages in a practical setting.

Increased Ductility and Formability

The most significant benefit is a dramatic increase in ductility. An annealed metal can be bent, stretched, or drawn into complex shapes without cracking.

This makes it essential for processes like deep drawing (forming sheet metal into cups) or wire drawing.

Reduced Hardness and Improved Machinability

Annealing softens the metal, which drastically improves its machinability.

A softer material is easier to cut, drill, and mill. This not only speeds up manufacturing processes but also significantly reduces wear and tear on cutting tools, lowering operational costs.

Relief of Internal Stresses

Processes like welding, casting, or heavy machining can introduce significant internal stresses into a material. These hidden stresses can cause the part to warp, distort, or even fail unexpectedly over time.

Annealing relieves these stresses by allowing the microstructure to settle into a stable, low-energy state, ensuring dimensional stability in the final product.

Enhanced Electrical Conductivity

For certain materials, particularly copper, a uniform and defect-free crystal structure improves electrical conductivity.

By reducing the dislocations that can impede the flow of electrons, annealing can optimize a metal for electrical applications.

Understanding the Trade-offs

While powerful, annealing is a process with specific outcomes and limitations that must be considered.

Loss of Strength and Hardness

The primary trade-off is that annealing produces a metal in its softest, weakest, and most ductile state.

While ideal for forming, this is often not desirable for the final application where strength and hardness are required. Therefore, annealing is frequently a preparatory step, followed by other heat treatments to achieve final strength.

Process Control is Critical

The annealing process requires precise control. The temperature, soaking time, and especially the cooling rate must be carefully managed for the specific alloy.

Furthermore, heating metal can cause surface oxidation. To prevent this, annealing is often performed in a controlled, inert atmosphere, such as a nitrogen gas mixture.

How to Apply This to Your Project

Choosing to anneal depends entirely on the material's current state and your next objective.

- If your primary focus is extensive shaping or forming: Annealing is essential to prevent fracture and allow for deep draws or complex bends.

- If your primary focus is improving machinability: Annealing will reduce tool wear and make cutting operations smoother, faster, and more cost-effective.

- If your primary focus is stabilizing a part after welding or casting: Annealing is the correct process for relieving internal stresses to prevent future distortion or failure.

- If your primary focus is maximizing final strength: View annealing as an intermediate step to make fabrication possible before a final hardening treatment.

Ultimately, annealing gives you deliberate control over a metal's internal structure, transforming a brittle, stressed material into a predictable and workable asset.

Summary Table:

| Benefit | Key Outcome |

|---|---|

| Increased Ductility | Enables complex shaping without cracking |

| Reduced Hardness | Improves machinability and reduces tool wear |

| Stress Relief | Prevents warping and ensures dimensional stability |

| Improved Conductivity | Optimizes electrical properties for materials like copper |

Ready to optimize your metalworking process?

Annealing is a critical step for achieving predictable and high-quality results. KINTEK specializes in providing the precise lab equipment and consumables needed for controlled heat treatment processes, including annealing.

Whether you are involved in R&D, quality control, or manufacturing, our solutions help you enhance ductility, improve machinability, and ensure material stability.

Contact our experts today to discuss how we can support your laboratory's specific metal annealing needs.

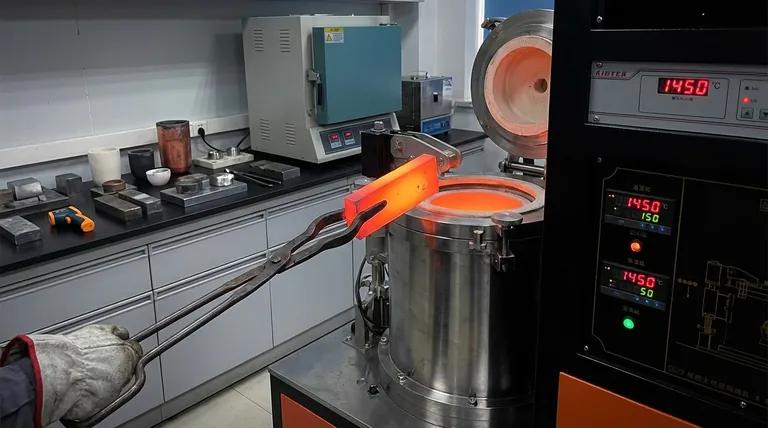

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vertical Laboratory Tube Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is the process of vacuum carburizing? Achieve Superior Case Hardening with Precision

- What are the problems with brazing? Managing Heat, Cleanliness, and Material Integrity

- What are the important safety precautions for heat treatment? Protect Your Team from Extreme Heat and Invisible Hazards

- What is brazing temperature for Aluminium? Master the Narrow Window for Strong Joints

- Why steam is added in pyrolysis furnace? Enhance Product Quality & Control Reaction Pathways

- What is the importance of using a vacuum drying oven in DMC catalyst prep? Unlock Peak Activity & Stability

- How does a high-temperature furnace with oxygen flow control ensure the quality of SiO2 layers? Achieve Precision Growth

- What are the benefits of vacuum annealing? Achieve Pristine, Oxide-Free Parts with Superior Material Properties