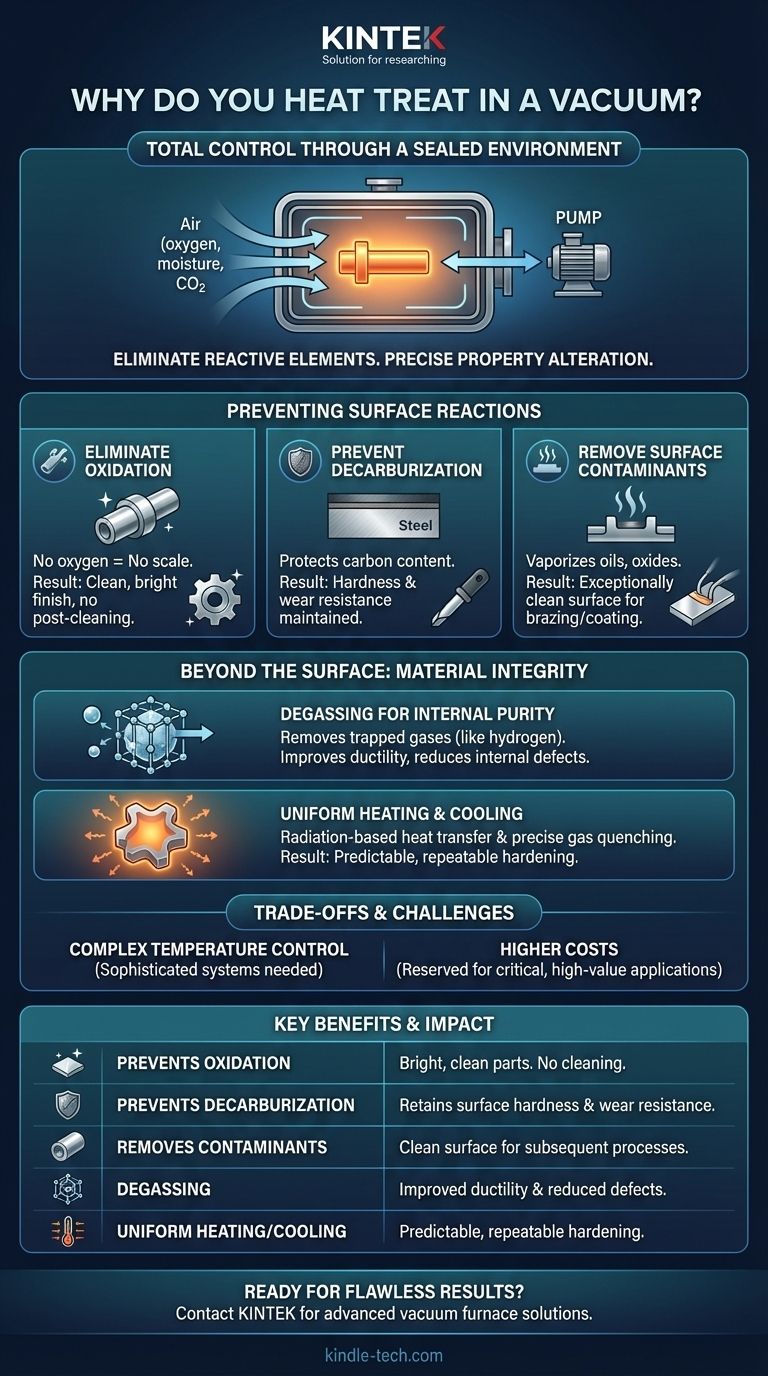

At its core, vacuum heat treating is about total control. This process is performed inside a sealed furnace where the air has been removed to create a vacuum. By eliminating atmospheric gases like oxygen, moisture, and carbon dioxide, you prevent them from reacting with the metal's surface at high temperatures. This ensures the material's properties are altered precisely as intended, without undesirable side effects like oxidation or decarburization.

The essential purpose of a vacuum furnace is to create a perfectly neutral environment. The goal isn't the vacuum itself, but the elimination of reactive elements to produce a perfectly clean, bright, and dimensionally stable component that often requires no post-treatment cleaning.

The Primary Goal: Preventing Surface Reactions

Heat treating relies on high temperatures to change a metal's microstructure. However, these same high temperatures dramatically accelerate chemical reactions between the metal and any gases present. A vacuum effectively removes the fuel for these unwanted reactions.

Eliminating Oxidation

At high temperatures, oxygen aggressively bonds with most metals to form a layer of oxide, commonly known as scale.

A vacuum environment is virtually free of oxygen, which prevents scale from forming. The result is a clean, bright surface finish straight out of the furnace, eliminating the need for subsequent cleaning operations like sandblasting or acid pickling.

Preventing Decarburization

Decarburization is the loss of carbon from the surface of steel. It is caused by oxygen and carbon dioxide reacting with the carbon in the alloy at high temperatures.

This loss of carbon creates a softer "skin" on the component, which compromises its surface hardness, wear resistance, and fatigue life. Vacuum heat treating protects the carbon content, ensuring the material's surface properties meet engineering specifications.

Removing Surface Contaminants

The combination of heat and vacuum can also have a cleaning effect on the parts themselves.

Trace amounts of residual oils, lubricants, and pre-existing thin oxide films can be vaporized and pulled away by the vacuum system. This leads to an exceptionally clean surface, ideal for subsequent processes like brazing or coating.

Beyond the Surface: Improving Material Integrity

The benefits of a vacuum environment extend deeper than just the surface of the metal, influencing its internal structure and overall performance.

Degassing for Internal Purity

Metals can contain dissolved gases, such as hydrogen, trapped within their crystalline structure during manufacturing.

Under vacuum, these dissolved gases can be pulled out of the metal, a process known as degassing. Removing them improves the material's ductility and reduces the risk of internal defects and hydrogen embrittlement.

Achieving Uniform Heating and Cooling

In a vacuum, heat transfer occurs primarily through radiation, not convection or conduction. This allows for exceptionally uniform heating of the entire workload, even for complex shapes.

This controlled environment also enables precise and often rapid quenching (cooling) using high-pressure inert gas. This combination of uniform heating and controlled cooling results in predictable, repeatable hardening and extends the life of the component.

Understanding the Trade-offs and Challenges

While powerful, vacuum heat treating is not a universal solution. It involves specific complexities and costs that make it better suited for certain applications over others.

The Complexity of Temperature Control

Heat transfer characteristics change dramatically as a furnace transitions from atmospheric pressure to a deep vacuum. The shift from convection to pure radiation requires highly sophisticated temperature control systems.

Even minor temperature overshoots are often unacceptable for high-performance alloys, demanding precise programming and soak guarantees to ensure the process stays within its tight operational window.

Higher Equipment and Process Costs

Vacuum furnaces are inherently more complex and expensive to build, operate, and maintain than standard atmospheric furnaces. This translates to a higher cost per part.

The process is therefore typically reserved for materials where the cost is justified by the performance requirements, such as high-alloy tool steels, aerospace components, and medical implants.

Making the Right Choice for Your Application

Selecting the right heat treatment process depends entirely on the material, the component's end-use, and your budget.

- If your primary focus is a perfect surface finish: Vacuum treating is ideal, as it eliminates oxidation and the need for post-process cleaning, delivering a bright, clean part.

- If your primary focus is maximum material hardness and performance: Vacuum treating prevents decarburization, ensuring the surface retains its full intended strength and wear resistance.

- If your primary focus is cost-effectiveness for general-purpose parts: A traditional atmospheric furnace may be sufficient if a perfect surface and absolute prevention of surface reactions are not critical.

Ultimately, choosing vacuum heat treatment is an investment in precision, purity, and predictable performance for your most critical components.

Summary Table:

| Key Benefit | Impact on the Component |

|---|---|

| Prevents Oxidation | Eliminates scale formation; parts come out bright and clean, often with no post-treatment cleaning needed. |

| Prevents Decarburization | Protects surface carbon content, ensuring hardness, wear resistance, and fatigue life meet specifications. |

| Removes Contaminants | Vaporizes oils and thin oxides for an exceptionally clean surface, ideal for brazing or coating. |

| Degassing | Removes dissolved gases like hydrogen, improving ductility and reducing internal defects. |

| Uniform Heating/Cooling | Enables precise, repeatable hardening through radiation-based heat transfer and controlled gas quenching. |

Ready to achieve flawless results for your critical components?

Vacuum heat treating is essential for achieving the precision, purity, and performance required by high-value industries like aerospace, medical, and tooling. KINTEK specializes in advanced lab equipment and consumables, providing the reliable vacuum furnace solutions your laboratory needs to ensure material integrity and superior surface finishes.

Contact our experts today to discuss how our vacuum furnaces can enhance your heat treatment processes and deliver predictable, high-quality results for your most demanding applications.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the different types of heat treatment process for steel? Tailor Strength, Hardness & Toughness

- How does heat treatment process work? Tailor Material Properties for Your Application

- What are the parts of a vacuum furnace? A Guide to the 5 Core Systems

- What are the three main heat treatments? Mastering Annealing, Hardening & Tempering

- What is a vacuum heat treatment furnace? The Ultimate Guide to Controlled Atmosphere Processing