At its core, low-temperature vacuum processing is a method of heating materials in a highly controlled, oxygen-free environment. A vacuum is first created to remove reactive gases, and then an inert gas is introduced before a precise heating and cooling cycle begins. This technique is used for thermal processes that require pristine surface quality and prevention of oxidation at temperatures lower than those used for hardening or brazing.

The term "low-temperature vacuum" can be misleading. It does not refer to a cold process, but rather to precise, gentle heating in an environment where oxygen and other contaminants have been completely removed to protect the integrity of the material.

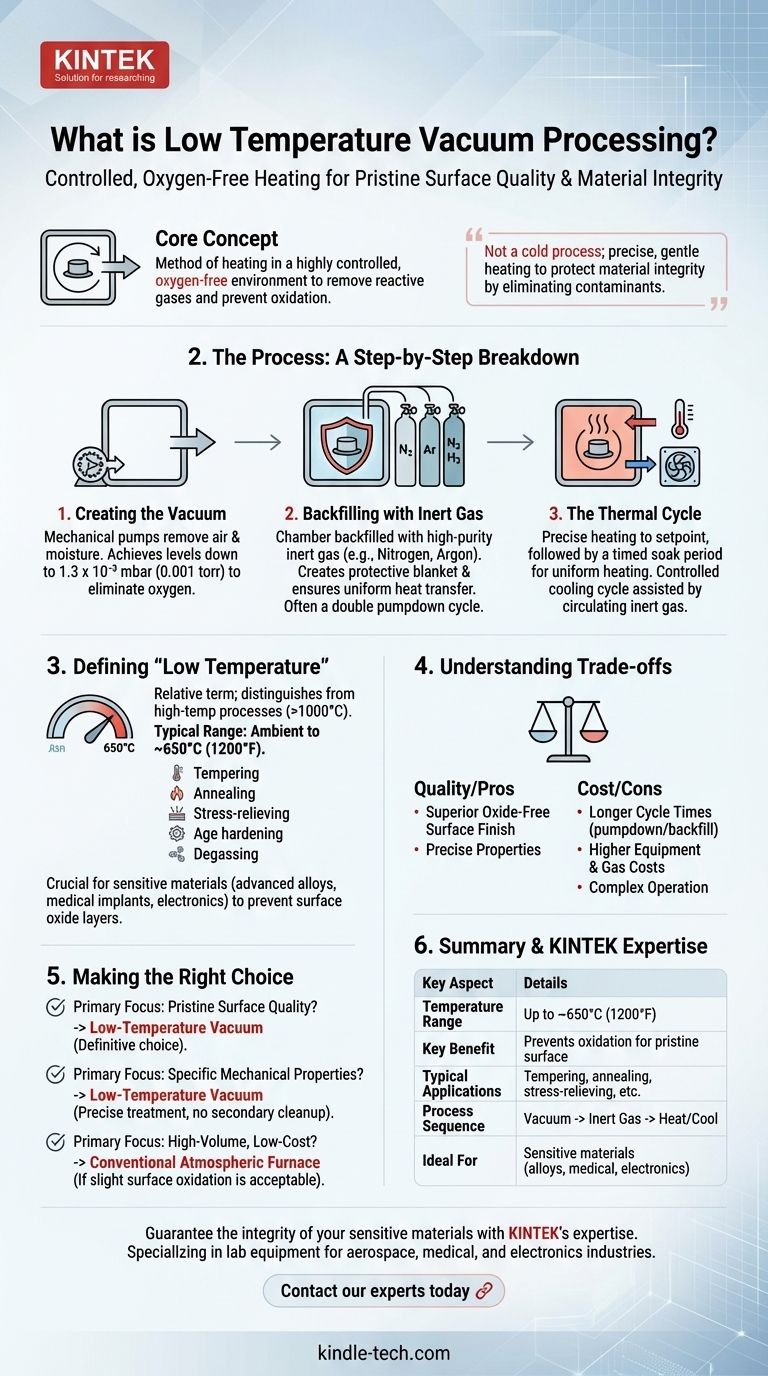

How the Process Works: A Step-by-Step Breakdown

A low-temperature vacuum process follows a precise sequence to ensure the material being treated is never exposed to a reactive atmosphere during heating. Each step is critical for the final outcome.

Step 1: Creating the Vacuum

The cycle begins by placing parts inside a sealed furnace chamber. Mechanical vacuum pumps are then activated to remove the air and moisture.

This pumpdown typically reaches vacuum levels down to 1.3 x 10⁻³ mbar (0.001 torr), which is sufficient to eliminate virtually all oxygen and other reactive gases that could tarnish or oxidize the material's surface.

Step 2: Backfilling with Inert Gas

Once the target vacuum level is achieved, the chamber is backfilled with a high-purity inert gas. This gas serves two purposes: it creates a protective, non-reactive "blanket" around the parts and provides a medium for uniform heat transfer.

Common gases include nitrogen, argon, or a nitrogen/hydrogen mixture, depending on the specific material and process requirements. To ensure maximum purity, this pumpdown and backfill cycle is often performed twice (double pumpdown).

Step 3: The Thermal Cycle

With the protective atmosphere established, the furnace begins to heat the chamber to the desired setpoint. The process includes a precisely timed soak period, where the material is held at temperature to ensure it is heated uniformly throughout.

After the soak is complete, a controlled cooling cycle begins, often aided by circulating the inert gas through a heat exchanger to bring the parts back to a safe handling temperature.

The Critical Role of "Low Temperature"

The term "low temperature" is relative in the world of thermal processing. It doesn't mean cold; it simply distinguishes these processes from high-temperature operations like brazing, sintering, or hardening, which can exceed 1000°C.

Defining the Temperature Range

Low-temperature vacuum processes typically operate anywhere from just above ambient temperature up to around 650°C (1200°F).

This range is ideal for applications like tempering, annealing, stress-relieving, age hardening, and degassing of sensitive materials that would be damaged by higher heat.

Why It's Necessary

Many advanced alloys, medical implants, and electronic components require thermal treatment to achieve their desired mechanical properties. However, even moderate heating in the presence of oxygen can create an undesirable oxide layer on the surface.

The vacuum environment ensures that these treatments can be performed without compromising surface finish, cleanliness, or material purity.

Understanding the Trade-offs

While powerful, low-temperature vacuum processing is not a universal solution. It involves specific trade-offs related to cost, complexity, and speed that must be considered.

Cycle Time vs. Quality

The pumpdown and backfill cycles add time to the overall process compared to simply heating parts in an atmospheric oven. This trade-off of longer cycle times is made to achieve a superior, oxide-free surface finish.

Equipment and Operational Costs

Vacuum furnaces are inherently more complex and expensive than their atmospheric counterparts. They require robust seals, pumping systems, and sophisticated controls, leading to higher initial investment and maintenance costs.

Furthermore, the continuous consumption of high-purity inert gas is a recurring operational expense.

Making the Right Choice for Your Goal

Deciding whether to use this process requires a clear understanding of your material's needs and your final quality requirements.

- If your primary focus is pristine surface quality: A low-temperature vacuum process is the definitive choice for preventing any oxidation on sensitive materials.

- If your primary focus is achieving specific mechanical properties: This method allows for precise tempering or annealing without the secondary cleanup costs associated with removing scale or discoloration.

- If your primary focus is high-volume, low-cost processing: A conventional atmospheric furnace may be more suitable, provided that a slight amount of surface oxidation is acceptable for the application.

Ultimately, choosing a low-temperature vacuum process is a strategic decision to guarantee superior material integrity when a clean, uncompromised surface is non-negotiable.

Summary Table:

| Key Aspect | Details |

|---|---|

| Temperature Range | Up to ~650°C (1200°F) |

| Key Benefit | Prevents oxidation for pristine surface quality |

| Typical Applications | Tempering, annealing, stress-relieving, age hardening, degassing |

| Process Sequence | Vacuum creation → Inert gas backfill → Precise heating/cooling |

| Ideal For | Sensitive materials like advanced alloys, medical implants, and electronics |

Guarantee the integrity of your sensitive materials with KINTEK's expertise.

If your application in aerospace, medical device manufacturing, or electronics requires a thermal process that delivers pristine, oxide-free surfaces and precise mechanical properties, our low-temperature vacuum solutions are engineered for your success. KINTEK specializes in the lab equipment and consumables that laboratories like yours depend on for precision and reliability.

Contact our experts today to discuss how we can support your specific thermal processing challenges and ensure superior results.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is quench annealing? A Specialized Heat Treatment for Corrosion Resistance and Strength

- What are the applications of sintering process? Fabricate Complex Parts with High-Performance Materials

- What type of furnace is used for metal casting? Choose the Right Furnace for Your Process

- What materials can be tempered? Unlock the Key to Hardness and Toughness in Steel

- What are the three heat treatment processes? Hardening, Annealing, and Tempering Explained

- What is the principle of sintering process? Transforming Powder into High-Performance Solids

- Can you braze thick aluminum? Yes, with the right heat and atmosphere control for strong joints.

- What is the application of vacuum brazing? Achieve Unmatched Joint Integrity for Critical Components