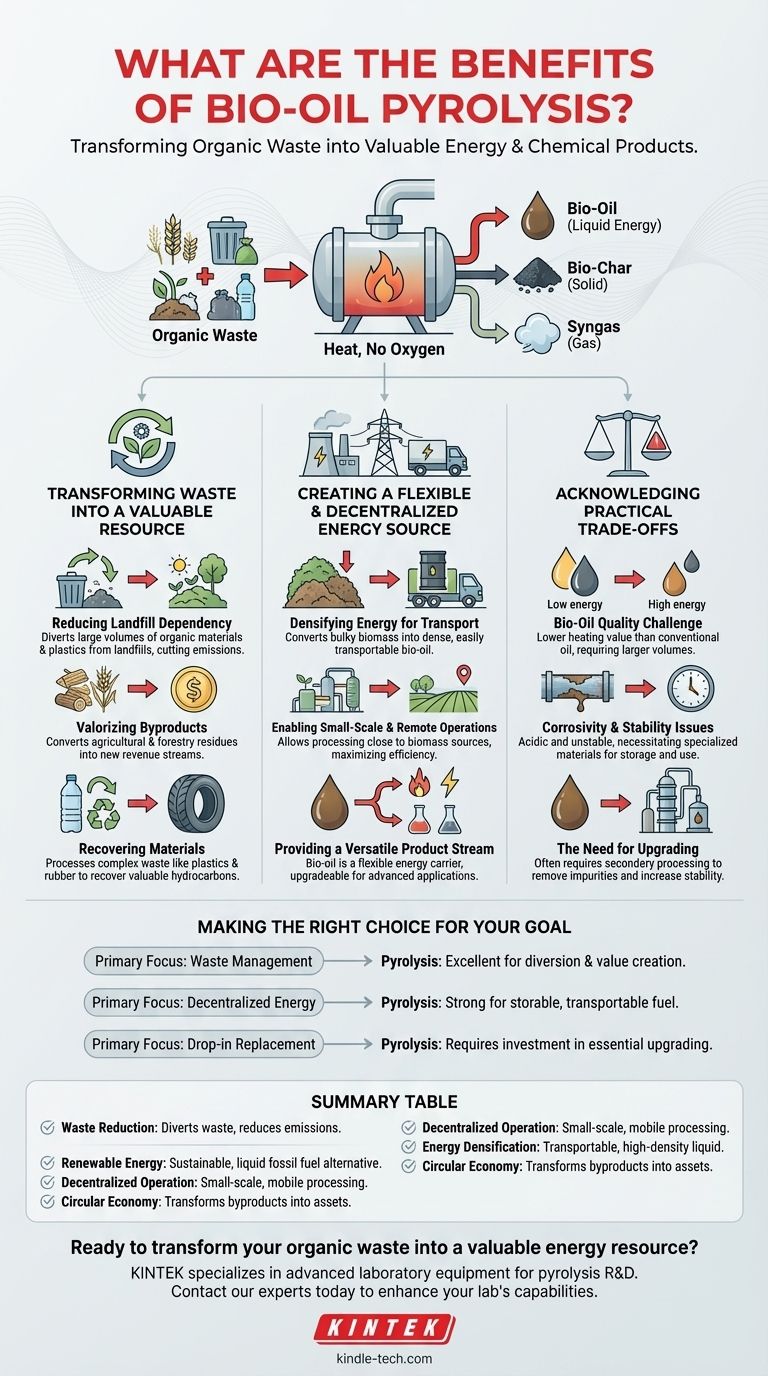

At its core, bio-oil pyrolysis is a thermochemical process that transforms organic waste into valuable energy and chemical products. Its primary benefits include significant waste reduction, the creation of a renewable alternative to fossil fuels, and the flexibility to operate in decentralized locations, turning low-value biomass into a high-density, transportable liquid fuel.

Pyrolysis should be viewed not just as a method for producing fuel, but as a strategic technology for building a circular economy. It fundamentally bridges the gap between waste management and sustainable energy production by converting liabilities like agricultural residue and municipal waste into assets.

Transforming Waste into a Valuable Resource

One of the most significant advantages of pyrolysis is its ability to reframe our concept of "waste." It is a powerful tool for waste valorization, the process of converting waste materials into more useful products.

Reducing Landfill Dependency

Pyrolysis directly diverts large volumes of organic materials, including agricultural residues and municipal solid waste, away from landfills. This reduces the environmental burden of landfilling, such as methane emissions and land use.

Valorizing Agricultural and Industrial Byproducts

Vast quantities of byproducts from forestry and agriculture, such as wood processing waste and crop residues, can be efficiently converted into bio-oil. This creates a new revenue stream from materials that would otherwise be considered waste.

Recovering Materials from Complex Waste

The technology is also capable of processing more complex waste streams, such as plastics and rubber. This enables the recovery of valuable hydrocarbons, reducing the environmental impact of plastic pollution and decreasing the need for virgin raw materials.

Creating a Flexible and Decentralized Energy Source

Beyond waste management, pyrolysis offers unique logistical and operational benefits that distinguish it from other renewable energy technologies. It excels at making biomass energy more practical and accessible.

Densifying Energy for Transport

Biomass is often bulky and has a low energy density, making it expensive to transport. Pyrolysis converts this solid biomass into a dense liquid bio-oil, which is far easier and cheaper to store and transport to a central refinery or power generation facility.

Enabling Small-Scale and Remote Operations

Pyrolysis reactors can be built on a relatively small, even mobile, scale. This allows for processing to occur close to the biomass source in remote locations, maximizing efficiency and minimizing handling costs.

Providing a Versatile Product Stream

The resulting bio-oil is a flexible energy carrier. It can be used directly for producing heat and power or be further upgraded into advanced biofuels and biochemicals, serving as a platform for a bio-based economy.

Acknowledging the Practical Trade-offs

To make an informed decision, it is critical to understand the challenges associated with raw bio-oil. While pyrolysis is effective, the direct output is not a "drop-in" replacement for petroleum without further treatment.

The Challenge of Bio-Oil Quality

The heating value of crude bio-oil is significantly lower than that of conventional heating oil, often by as much as 50%. This means a larger volume of bio-oil is needed to produce the same amount of energy.

Corrosivity and Stability Issues

Bio-oil is highly acidic and contains water, making it corrosive to common metals like steel. This necessitates the use of specialized, more expensive materials for storage tanks, pipes, and engine components. It can also be unstable over time.

The Need for Upgrading

Due to its corrosivity, lower energy content, and potential contaminants, bio-oil almost always requires an "upgrading" step. This secondary process adds complexity and cost to remove oxygen, increase its heating value, and improve its stability before it can effectively compete with fossil fuels.

Making the Right Choice for Your Goal

Pyrolysis offers a powerful set of benefits, but its suitability depends entirely on your specific objective. The decision to invest in this technology should be made with a clear understanding of its strengths and the necessary downstream processing.

- If your primary focus is waste management: Pyrolysis is an exceptional technology for diverting organic waste from landfills and creating value from agricultural or industrial byproducts.

- If your primary focus is decentralized energy production: It is a strong option for converting locally available biomass into a storable, transportable liquid fuel, especially in remote areas.

- If your primary focus is creating a drop-in fossil fuel replacement: Be prepared to invest in the essential upgrading processes required to overcome bio-oil's inherent quality and corrosivity challenges.

Ultimately, pyrolysis provides a robust and proven pathway to unlock the latent energy and value stored within organic waste streams.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Waste Reduction | Diverts organic & plastic waste from landfills, reducing methane emissions. |

| Renewable Energy | Creates a sustainable, liquid bio-oil alternative to fossil fuels. |

| Decentralized Operation | Enables small-scale, mobile processing close to biomass sources. |

| Energy Densification | Converts bulky biomass into a transportable, high-density liquid fuel. |

| Circular Economy | Transforms agricultural and industrial byproducts into valuable assets. |

Ready to transform your organic waste into a valuable energy resource?

KINTEK specializes in advanced laboratory equipment and consumables for pyrolysis research and development. Whether you are optimizing your pyrolysis process, analyzing bio-oil quality, or scaling up production, our precise and reliable solutions are designed to support your innovation in sustainable energy.

Contact our experts today to discuss how KINTEK can enhance your lab's capabilities and help you build a more sustainable future.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products