In essence, pelletizing biomass transforms it into a superior material. The process provides significant benefits in handling, transportation, and performance by converting inconsistent raw biomass into a dense, uniform, and flowable commodity.

The core value of pelletization is one of transformation. It takes a low-value, difficult-to-manage raw material and upgrades it into a standardized, predictable, and economically viable fuel or product.

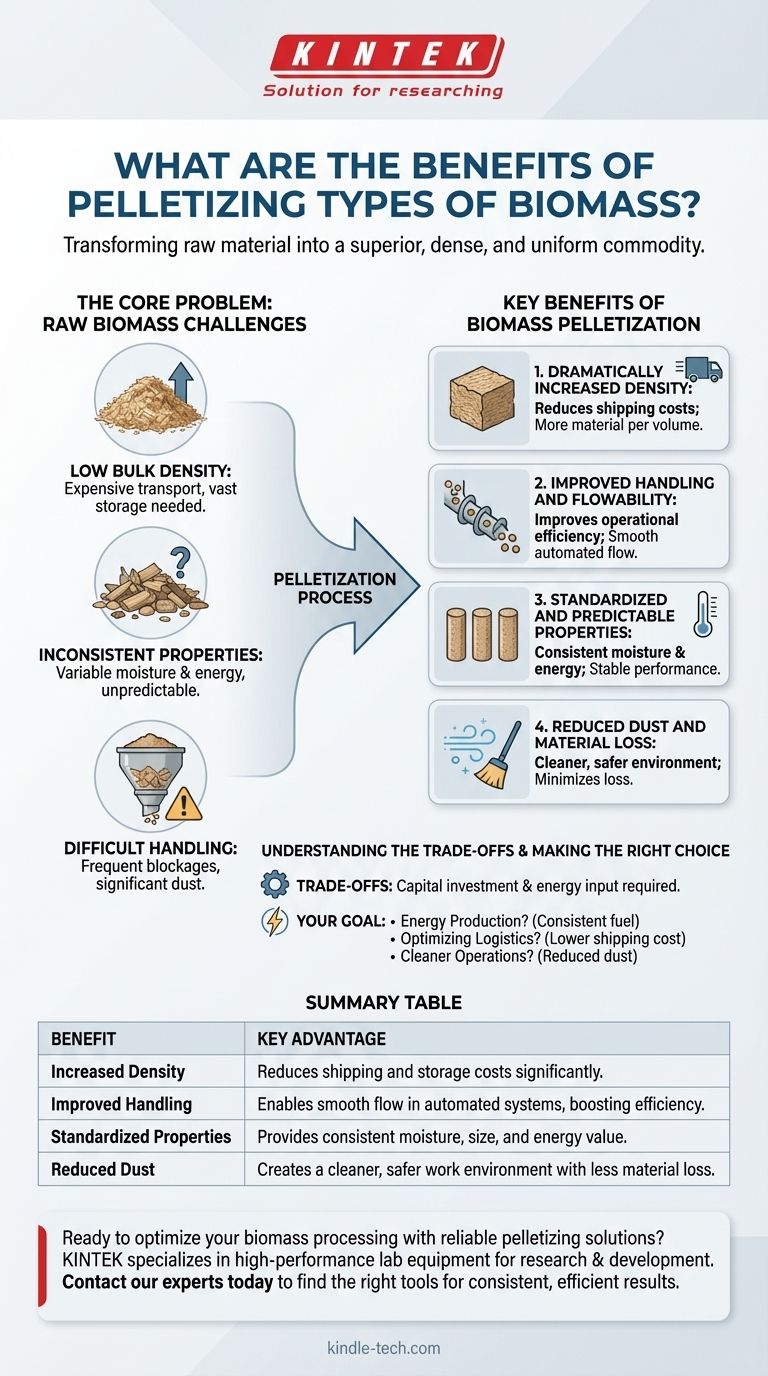

The Core Problem: Raw Biomass Challenges

Before understanding the benefits, it's crucial to recognize the inherent difficulties of working with raw biomass, such as wood chips, sawdust, or agricultural residues.

Low Bulk Density

Raw biomass is often light and fluffy. This low density makes it expensive to transport and requires vast areas for storage, creating significant logistical and economic hurdles.

Inconsistent Properties

Moisture content, particle size, and energy value can vary dramatically in raw biomass. This inconsistency makes it extremely difficult to use in automated systems and leads to unpredictable performance.

Difficult Handling

The irregular shapes and sizes of raw biomass cause frequent blockages in feeding systems. It also generates significant dust, creating health, safety, and operational challenges.

Key Benefits of Biomass Pelletization

Pelletizing directly addresses the fundamental challenges of raw biomass, unlocking its potential as a reliable resource.

Benefit 1: Dramatically Increased Density

By compressing the material, pelletization significantly increases its bulk density. This is arguably the most important economic advantage.

A higher density means more material can be stored in a given volume and, critically, more fuel can be transported in a single truckload, drastically reducing shipping costs.

Benefit 2: Improved Handling and Flowability

Pellets have a uniform, cylindrical shape and a smooth surface. This allows them to flow like a liquid through automated augers, conveyors, and feeding systems.

This improves operational efficiency, reduces manual intervention, and enables precise metering of the material into combustion or production processes.

Benefit 3: Standardized and Predictable Properties

The pelletizing process dries and homogenizes the biomass. The final pellets have a consistent moisture content, size, and energy value.

This standardization ensures predictable and stable performance, whether the pellets are used for heat generation or other industrial applications.

Benefit 4: Reduced Dust and Material Loss

The compression process binds fine particles together, minimizing dust during transport and handling.

This not only creates a cleaner and safer working environment but also reduces material loss, ensuring that more of the biomass you procure ends up serving its intended purpose.

Understanding the Trade-offs

While highly beneficial, pelletization is not a cost-free process. A clear understanding of the downsides is essential for a complete picture.

The Cost of Production

Pelletizing is an industrial process that requires a significant capital investment in machinery like grinders, dryers, and pellet mills. These machines also have ongoing operational and maintenance costs.

Required Energy Input

The process of drying and compressing biomass consumes a notable amount of energy. This energy expenditure must be factored into the net energy balance and overall cost-effectiveness of the final product.

Making the Right Choice for Your Goal

The decision to use pelletized biomass depends entirely on your operational priorities.

- If your primary focus is large-scale energy production: The consistent moisture and energy content of pellets provide the fuel standardization needed for efficient, automated combustion.

- If your primary focus is optimizing logistics and transport: The dramatic increase in bulk density is the key benefit, as it directly translates to lower shipping and storage costs per unit of energy.

- If your primary focus is cleaner, safer operations: The reduction of dust and the excellent flowability of pellets will be the most impactful advantages for your facility.

Ultimately, pelletizing is the critical value-adding step that makes biomass a functional and competitive commodity in the modern economy.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Increased Density | Reduces shipping and storage costs significantly. |

| Improved Handling | Enables smooth flow in automated systems, boosting efficiency. |

| Standardized Properties | Provides consistent moisture, size, and energy value. |

| Reduced Dust | Creates a cleaner, safer work environment with less material loss. |

Ready to optimize your biomass processing with reliable pelletizing solutions? KINTEK specializes in high-performance lab equipment and consumables for biomass research and development. Whether you're testing pellet quality, analyzing moisture content, or scaling up production, our tools help you achieve consistent, efficient results. Contact our experts today to find the right equipment for your laboratory needs and take the first step toward superior biomass handling!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What are the different parts of a single punch tablet machine? The Core Components Explained

- Are wood pellets made from sawdust? Unlock the Secret to High-Performance Fuel

- What are the steps of tablet production by direct compression? Streamline Your Manufacturing Process

- What components of a tablet press define the size and shape of the tablets? Mastering Die and Punch Tooling

- What is the process of pelleting biomass? Transform Raw Biomass into High-Value, Energy-Dense Fuel

- What are pill presses used for? Transforming Powders into Precise Tablets for Medicine, Supplements, and More

- What are pill presses called? The Correct Term is Tablet Press for Pharmaceutical Manufacturing

- What is the principle of a single punch tablet press machine? A Guide to Precision Lab-Scale Production