In short, PVD (Physical Vapor Deposition) coatings are available in a wide spectrum of colors, including popular metallic shades like gold, rose gold, bronze, chrome, and gunmetal, as well as non-metallic colors such as black, blue, purple, and green. The final color is not a paint or dye but is determined by the specific material deposited and the precise parameters of the coating process.

The key to understanding PVD color is realizing it’s a function of physics, not pigment. The color you see is the result of a microscopically thin layer of ceramic or metal material manipulating light, which offers incredible durability but also introduces unique considerations for color matching.

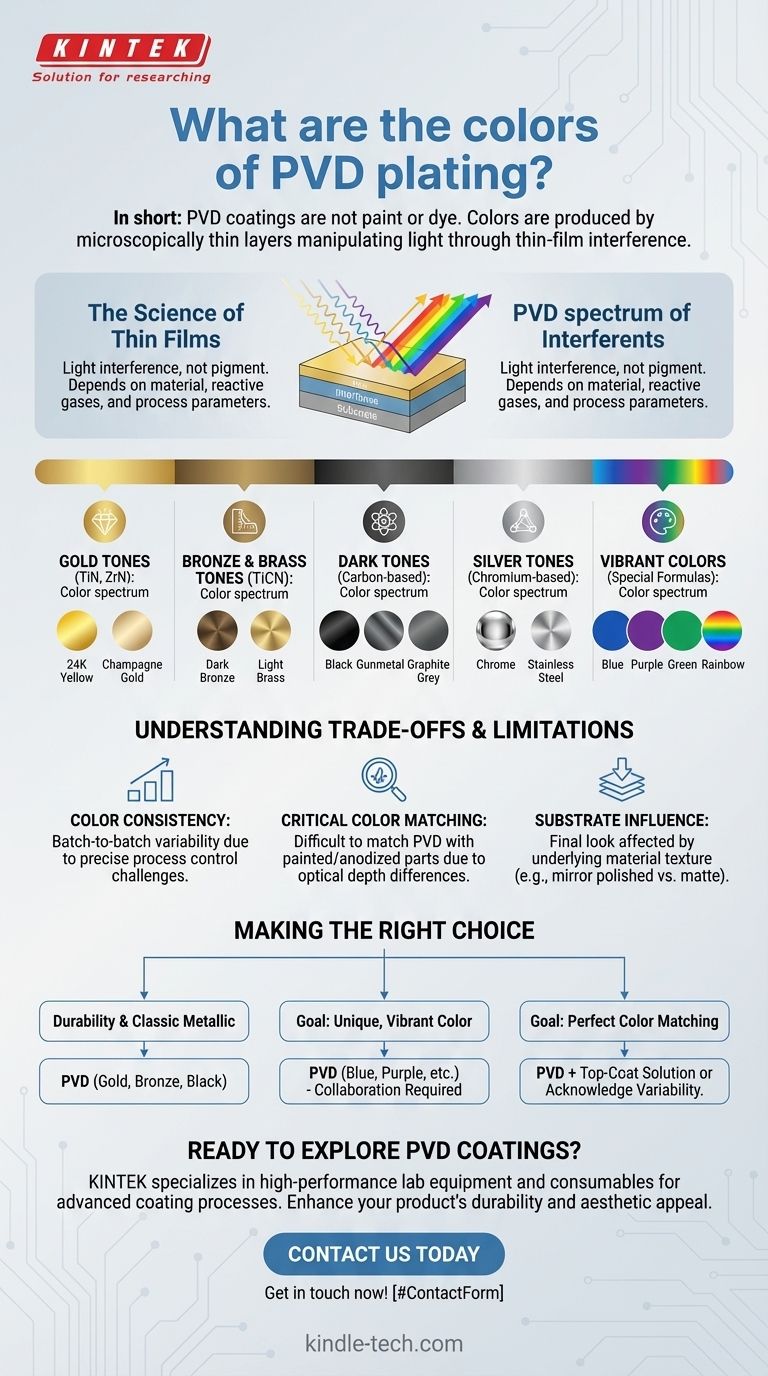

How PVD Creates Color: The Science of Thin Films

To select the right PVD color, you must first understand that the process is fundamentally different from painting or plating. It is a vacuum deposition method that produces a thin, bonded, hard coating on the surface of a part.

It's Not a Paint, It's Light Interference

PVD color is achieved through a phenomenon called thin-film interference. The coating is so thin—often just a few hundred nanometers—that it selectively reflects and cancels out certain wavelengths of light.

What you perceive as color is the light that is reflected back to your eye. This is the same principle that gives soap bubbles or a drop of oil on water their rainbow-like shimmer.

The Role of Material and Process

The specific color is dictated by the material being deposited and the reactive gases used in the vacuum chamber.

For example, Titanium Nitride (TiN) produces a classic gold color. By introducing carbon, it becomes Titanium Carbonitride (TiCN), which appears as a shade of brass or bronze. Using a different base material, like Zirconium Nitride (ZrN), yields a pale gold or champagne color. More exotic colors like blue and purple are also achieved with specific compound formulas.

The Spectrum of Available Finishes

This process unlocks a rich palette that can be applied to metals and even some plastics. Common colors include:

- Gold Tones: Ranging from 24K yellow gold to lighter champagne golds.

- Bronze & Brass Tones: From dark, oil-rubbed bronze to lighter brass shades.

- Dark Tones: Rich black, gunmetal, and graphite grey.

- Silver Tones: Bright chrome and stainless steel looks.

- Vibrant Colors: Blues, purples, greens, and rainbow effects are possible with specific material compositions.

Understanding the Trade-offs and Limitations

While PVD is a superior coating technology, it is not without its specific constraints. Understanding these is critical for successful product design and manufacturing.

Color Consistency Across Batches

Because PVD color depends on precise control of vacuum pressure, temperature, and gas composition, achieving a 100% identical color match from one batch to the next is a significant technical challenge.

Reputable providers have stringent process controls to minimize this variability, but minor shifts can occur. This is a known factor in high-volume production.

The Challenge of Critical Color Matching

If your goal is to perfectly match a PVD-coated component to a painted or anodized part, you will face difficulty. PVD colors have a different optical depth and "life" to them because they are not based on pigments.

For applications requiring absolute color uniformity across different materials and parts, a secondary protective or colored layer may need to be applied over the PVD coating.

Substrate Influence on Final Appearance

The final look is a combination of the PVD color and the texture of the underlying material, or substrate.

A gold PVD coating applied over a mirror-polished part will look bright and reflective. The exact same coating applied over a bead-blasted or brushed surface will appear matte or satin. This must be accounted for in the design phase.

Making the Right Choice for Your Application

Your final decision should be guided by your primary goal for the finish.

- If your primary focus is durability with a classic metallic look: PVD is the premier choice for achieving authentic and wear-resistant gold, bronze, or black finishes.

- If your primary focus is a unique, vibrant color: PVD can create stunning blues, purples, and other shades, but be prepared to work closely with your vendor to define the exact material compound needed.

- If your primary focus is perfect color matching across a product line: Acknowledge that PVD has inherent variability and plan your quality control process accordingly, or explore a combined PVD and top-coat solution.

Ultimately, leveraging PVD color successfully comes from treating it as an integral part of the engineering process, not just a final decorative step.

Summary Table:

| Color Category | Common Examples | Key Material/Process |

|---|---|---|

| Gold Tones | 24K Yellow Gold, Champagne Gold | Titanium Nitride (TiN), Zirconium Nitride (ZrN) |

| Bronze & Brass Tones | Dark Bronze, Light Brass | Titanium Carbonitride (TiCN) |

| Dark Tones | Black, Gunmetal, Graphite Grey | Various carbon-based compounds |

| Silver Tones | Chrome, Stainless Steel Looks | Chromium-based coatings |

| Vibrant Colors | Blue, Purple, Green, Rainbow | Specialized compound formulas |

Ready to explore the perfect PVD coating for your application?

At KINTEK, we specialize in providing high-performance lab equipment and consumables for advanced coating processes. Whether you're in manufacturing, jewelry, or electronics, our expertise ensures you achieve the durable, vibrant finish your products deserve.

Contact us today to discuss your PVD coating needs and discover how our solutions can enhance your product's durability and aesthetic appeal. Get in touch now!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Quartz Tube Furnace Tubular RTP Heating Furnace

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

People Also Ask

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application