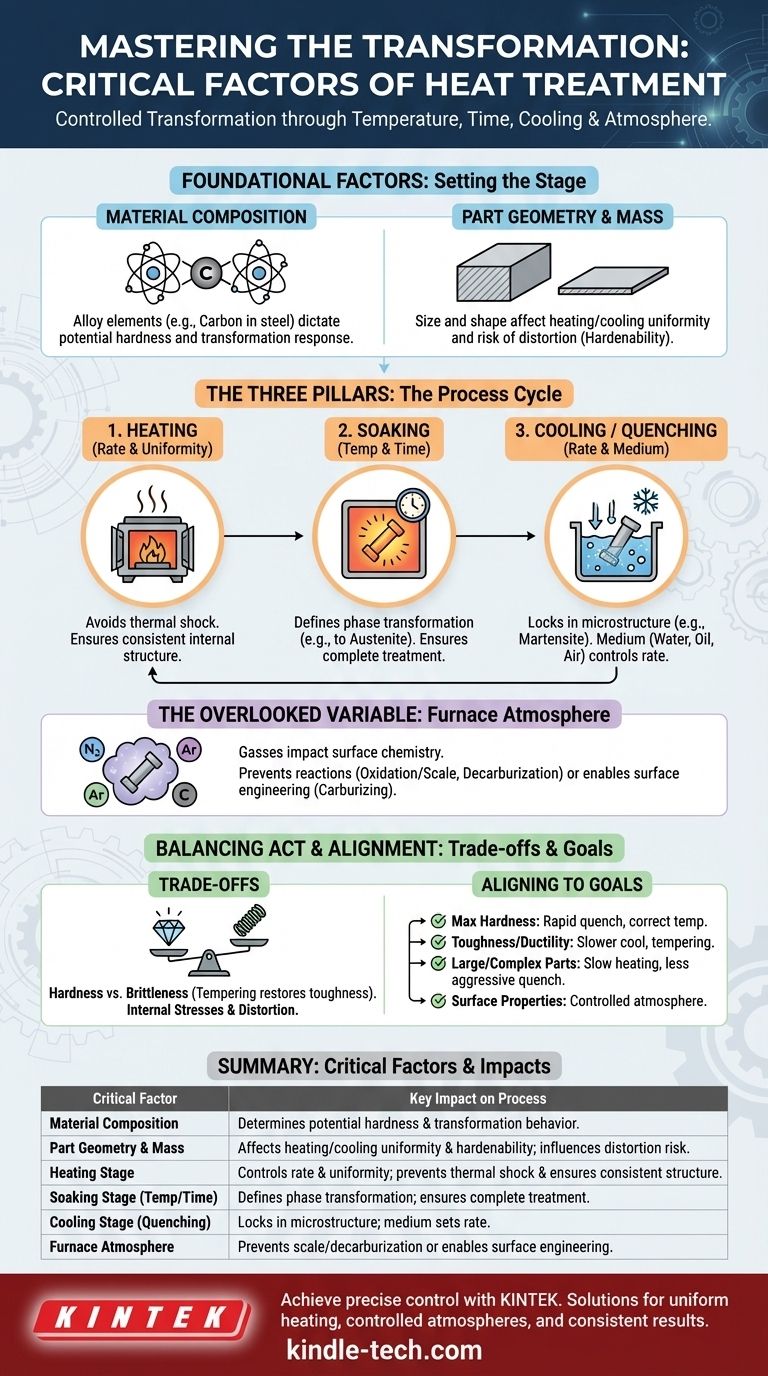

Ultimately, heat treatment is a process of controlled transformation. The final properties of a metal component are determined by four critical factors: the temperature it is heated to, the amount of time it is held at that temperature, the rate at which it is cooled, and the atmosphere surrounding it during the process. These variables are not independent; their interplay is dictated by the material's composition and the part's physical size.

Heat treatment is not about following a static recipe; it is the deliberate manipulation of a metal's internal crystalline structure. Mastering the relationship between time, temperature, and cooling is the key to unlocking a specific, desired performance characteristic, from extreme hardness to high ductility.

Foundational Factors: Material and Geometry

Before the process even begins, two factors set the stage for the outcome. They define the material's potential and its physical limitations.

Material Composition

The specific alloy being treated is the most fundamental factor. Different elements within the metal dictate how it responds to heat.

For example, the carbon content in steel is the primary driver of its potential hardness. Other alloying elements like chromium, molybdenum, and nickel change the timing and temperatures of transformations, influencing properties like corrosion resistance, high-temperature strength, and toughness.

Part Geometry and Mass

The size and shape of the component have a profound impact on the process. A thick, massive part heats and cools far more slowly than a thin one.

This variation means a thick section may not cool quickly enough to achieve the same hardness as a thin section, a concept known as hardenability. Complex geometries can also create internal stresses during rapid cooling, leading to distortion or even cracking.

The Three Pillars of the Heat Treatment Cycle

Every heat treatment process consists of three distinct stages. Control over each stage is essential for a predictable result.

The Heating Stage: Rate and Uniformity

The rate at which a part is brought to temperature is the first control point. Heating too quickly can cause thermal shock, especially in complex or brittle materials, leading to cracks.

The goal is to achieve a uniform temperature throughout the part's cross-section. Uneven heating leads to an inconsistent internal structure and, therefore, inconsistent final properties.

The Soaking Stage: Temperature and Time

Once at the target temperature, the part is "soaked" for a specific duration. This is arguably the most critical stage.

The soaking temperature determines which phase transformation occurs. In steel, this means heating to a temperature high enough to transform the microstructure into austenite.

The soaking time ensures this transformation is complete through the entire volume of the part. Insufficient time, especially in thick sections, will result in a soft core and an incompletely treated component.

The Cooling Stage (Quenching): Rate and Medium

The rate of cooling dictates the final microstructure and thus the material's final properties. This is where the transformation achieved during soaking is locked into place.

A very fast cool, or quench, traps carbon in steel to form a hard, brittle structure called martensite. A slower cool allows for the formation of softer, more ductile structures like pearlite or bainite.

The cooling rate is controlled by the quenching medium. Water provides a very fast quench, oil is less severe, and forced air or still air is slowest.

The Overlooked Variable: Furnace Atmosphere

The gasses surrounding the part during heating have a significant chemical effect on its surface.

Preventing Surface Reactions

In a normal air atmosphere, the oxygen will react with the hot metal surface, causing oxidation (scale). The carbon at the surface can also be burned away, a highly undesirable effect known as decarburization, which leaves the surface soft.

To prevent this, processes are often run in a vacuum or in a controlled, inert atmosphere (like nitrogen or argon).

Active Atmospheres for Surface Engineering

Conversely, some processes deliberately use an active atmosphere to change the surface chemistry. In carburizing, a carbon-rich atmosphere is used to diffuse additional carbon into the surface of a low-carbon steel part, allowing it to be hardened.

Understanding the Trade-offs

Choosing heat treatment parameters is always an exercise in balancing competing properties.

Hardness vs. Brittleness

The primary trade-off in hardening steel is between hardness and brittleness. A fully quenched, martensitic steel is extremely hard but too brittle for most applications. This is why a secondary heat treatment, tempering, is almost always performed to restore some ductility and toughness at the expense of some hardness.

Internal Stresses and Distortion

Rapid or non-uniform cooling creates immense internal stresses within a part. These stresses can relieve themselves by causing the part to warp or distort. In severe cases, the stress can exceed the material's strength, causing quench cracking.

Through-Hardening vs. Case-Hardening

It is difficult to achieve full hardness throughout the cross-section of a very thick component because the core cannot cool fast enough. This is a limitation of the material's hardenability. For such cases, case-hardening (like carburizing) is used to create a hard, wear-resistant surface while leaving a softer, tougher core.

Aligning Process to Performance Goals

The correct parameters are determined entirely by your desired outcome. Use these principles to guide your decisions.

- If your primary focus is maximum hardness: Prioritize achieving the correct austenitizing temperature and employ a rapid quench medium appropriate for the alloy.

- If your primary focus is toughness and ductility: Utilize slower cooling rates or follow your quench with a carefully controlled tempering cycle.

- If you are working with large or complex parts: Emphasize slow, uniform heating and consider a less aggressive quench (e.g., oil instead of water) to minimize distortion and the risk of cracking.

- If surface properties are critical: You must control the furnace atmosphere to prevent decarburization or actively use it for a case-hardening process.

By understanding these factors not as independent variables but as an interconnected system, you gain precise control over the final performance of your material.

Summary Table:

| Critical Factor | Key Impact on Process |

|---|---|

| Material Composition | Determines potential hardness and transformation behavior (e.g., carbon content in steel). |

| Part Geometry & Mass | Affects heating/cooling uniformity and hardenability; influences risk of distortion. |

| Heating Stage | Controls rate and uniformity; prevents thermal shock and ensures consistent structure. |

| Soaking Stage (Temp/Time) | Defines phase transformation (e.g., austenite in steel); ensures complete treatment. |

| Cooling Stage (Quenching) | Locks in microstructure (e.g., martensite for hardness); medium (water, oil, air) sets rate. |

| Furnace Atmosphere | Prevents scale/decarburization or enables surface engineering (e.g., carburizing). |

Achieve precise control over your heat treatment outcomes with KINTEK. Whether you need maximum hardness, superior toughness, or minimized distortion for complex parts, our lab equipment and consumables are engineered for reliability and repeatability. We specialize in serving laboratory needs with solutions that ensure uniform heating, controlled atmospheres, and consistent results. Ready to optimize your process? Contact our experts today to discuss your specific requirements and discover how KINTEK can enhance your lab's capabilities.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the purpose of the specific loading arrangement in a high-temperature furnace during the Exo-Melt process?

- What is the temperature range for sintering? A Guide to the 0.6-0.8 Tm Rule for Stronger Materials

- What is the VAR melting process? The Ultimate Guide to Vacuum Arc Remelting

- Can you heat treat metal twice? Correct Flaws and Adapt Parts with Multiple Cycles

- What does quenching do in heat treatment? Control Cooling Rates to Achieve Desired Material Properties

- Is sintering better than melting? Choosing the Right Process for Your Materials

- What temperature is a hardening furnace? Achieve Precise Heat Treatment for Superior Metal Hardness

- What are the benefits of heat treatment? Enhance Material Strength, Durability, and Performance