Brazing is a highly versatile metal-joining process, distinguished by the method used to apply heat. The primary types include torch brazing, furnace brazing, induction brazing, dip brazing, and resistance brazing. The optimal choice is not based on a single "best" method, but on a careful evaluation of production volume, material types, joint complexity, and cost requirements.

Choosing the right brazing method is fundamentally about selecting the most effective heating technique. The goal is to match the method's characteristics—speed, precision, volume capacity, and cost—to the specific demands of your application.

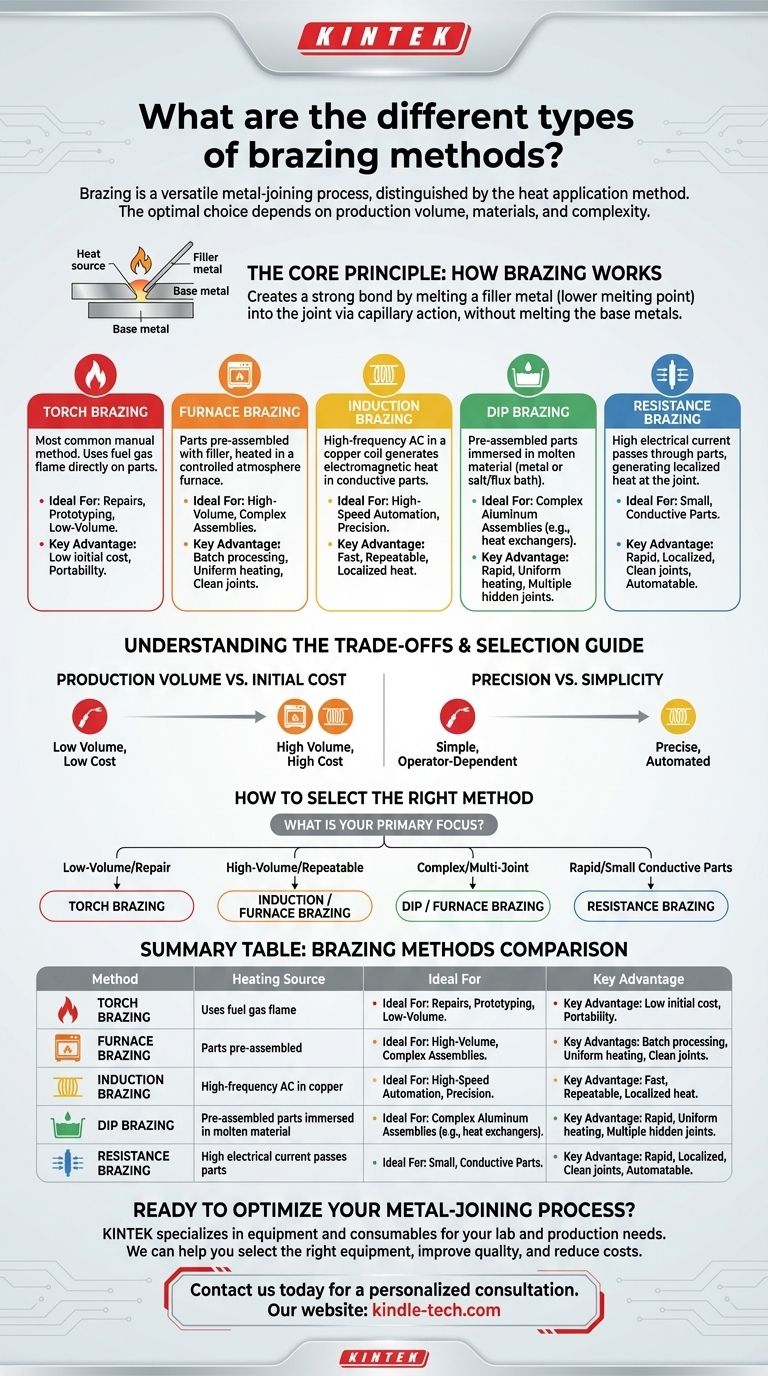

The Core Principle: How Brazing Works

Brazing creates a strong, permanent bond between two or more metal parts by melting a filler metal and drawing it into the joint through capillary action. The key is that the filler metal has a lower melting point than the base metals being joined. The base metals are heated to a temperature sufficient to melt the filler, but not themselves.

Different brazing methods are simply different ways of delivering this required heat to the assembly. Each method has a distinct profile of how it heats the parts, which makes it suitable for different situations.

Common Brazing Methods: A Detailed Comparison

Understanding the mechanics and ideal use cases for each heating method is critical for process selection.

Torch Brazing

This is the most common manual brazing method. A fuel gas (like acetylene or propane) mixed with oxygen or air is used to create a flame that is applied directly to the parts near the joint.

Torch brazing is highly portable and requires a relatively low initial investment. It is ideal for repairs, prototyping, and low-volume production where automation is not practical. However, it is highly dependent on operator skill for quality and consistency.

Furnace Brazing

In furnace brazing, the parts are pre-assembled with the filler metal placed at the joints. The entire assembly is then loaded into a furnace and heated to the brazing temperature in a controlled environment.

This method is perfect for high-volume production and complex assemblies with multiple or inaccessible joints. The controlled atmosphere (either a vacuum or a specific gas mixture) prevents oxidation, often resulting in clean, high-quality joints that require no post-braze cleaning.

Induction Brazing

This method uses a high-frequency alternating current passed through a copper coil. The coil, which does not touch the part, generates an electromagnetic field that rapidly heats the conductive metal parts placed within it.

Induction brazing is exceptionally fast, precise, and repeatable, making it ideal for high-speed automated production lines. Heat can be localized to a very specific area, minimizing distortion and protecting sensitive components.

Dip Brazing

Dip brazing involves immersing the pre-assembled parts into a bath of molten material. There are two primary types: molten metal dip brazing and molten salt (or flux) dip brazing.

This technique provides rapid, uniform heating and is especially effective for complex aluminum assemblies like heat exchangers with many hidden joints. The bath provides both heat and, in the case of a salt bath, fluxing action to clean the parts.

Resistance Brazing

Similar to resistance welding, this method passes a high electrical current through the parts being joined. The inherent resistance of the materials at the joint interface generates intense, localized heat to melt the filler metal.

Resistance brazing is useful for joining small, electrically conductive components where heat must be applied very quickly and locally. It is a clean process well-suited for automation.

Understanding the Trade-offs

No single method is universally superior. The right choice always involves balancing competing priorities.

Production Volume vs. Initial Cost

Torch brazing has the lowest capital cost but the highest per-unit labor cost, making it suitable for small runs. Furnace and induction brazing require significant initial investment but offer the lowest per-unit cost at high volumes due to automation and batch processing.

Precision vs. Simplicity

Induction brazing offers the highest degree of precision and control, allowing for exact, repeatable heating cycles. Torch brazing is simpler in terms of equipment but relies entirely on operator skill to control heat input, which can lead to inconsistency.

Joint Complexity and Accessibility

For parts with intricate designs or multiple joints that are hard to reach, furnace and dip brazing are superior. They heat the entire assembly uniformly, ensuring that all joints, even internal ones, reach the proper temperature for the filler metal to flow.

How to Select the Right Method for Your Application

Use your primary goal as the starting point for narrowing down the best process.

- If your primary focus is low-volume production or repair work: Torch brazing offers the lowest initial investment and greatest flexibility for one-off jobs.

- If your primary focus is high-volume, repeatable manufacturing: Induction brazing provides unmatched speed and precision, while furnace brazing is ideal for processing many complex parts in a single batch.

- If your primary focus is joining complex, multi-joint assemblies like heat exchangers: Dip brazing or furnace brazing are superior for ensuring uniform heating and complete joint penetration.

- If your primary focus is rapid, localized joining of small conductive parts: Resistance brazing offers a highly efficient and targeted heating solution.

By understanding these core methods and their trade-offs, you can confidently select the process that delivers the strength, quality, and efficiency your project demands.

Summary Table:

| Brazing Method | Heating Source | Ideal For | Key Advantage |

|---|---|---|---|

| Torch Brazing | Gas Flame | Repairs, Prototyping, Low Volume | Low initial cost, Portability |

| Furnace Brazing | Controlled Oven | High Volume, Complex Assemblies | Batch processing, Uniform heating |

| Induction Brazing | Electromagnetic Field | High-Speed Automation, Precision | Fast, repeatable, localized heat |

| Dip Brazing | Molten Bath | Complex Aluminum Assemblies | Uniform heating, multiple hidden joints |

| Resistance Brazing | Electrical Current | Small Conductive Parts | Rapid, localized, clean joints |

Ready to Optimize Your Metal-Joining Process?

Choosing the right brazing method is critical for achieving strong, reliable joints while maximizing efficiency and controlling costs. The experts at KINTEK are here to help. We specialize in providing the ideal lab equipment and consumables for your brazing applications, whether you're in R&D, prototyping, or full-scale production.

We can help you:

- Select the right brazing equipment for your specific materials and production volume.

- Improve joint quality and consistency.

- Increase throughput and reduce operational costs.

Contact us today for a personalized consultation and let KINTEK be your partner in precision metal-joining. Get in touch via our contact form to discuss your project needs!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the safety precautions when using a test tube? Essential Lab Safety Guidelines

- How hot can a metal surface get in the sun? The Surprising Science Behind Extreme Heat

- How does heat treatment affect strength? Tailor Material Properties for Maximum Performance

- Which furnace is generally more efficient? Match the Right Furnace to Your Heating Goals

- What is sintering effect? Transform Powder into Durable, High-Performance Parts

- Why is sintering needed? Create High-Performance Components Without Melting

- Are electric arc furnaces efficient? Unlocking Modern Steelmaking's Power and Flexibility

- Which metal is harder to melt? Tungsten Leads with the Highest Melting Point