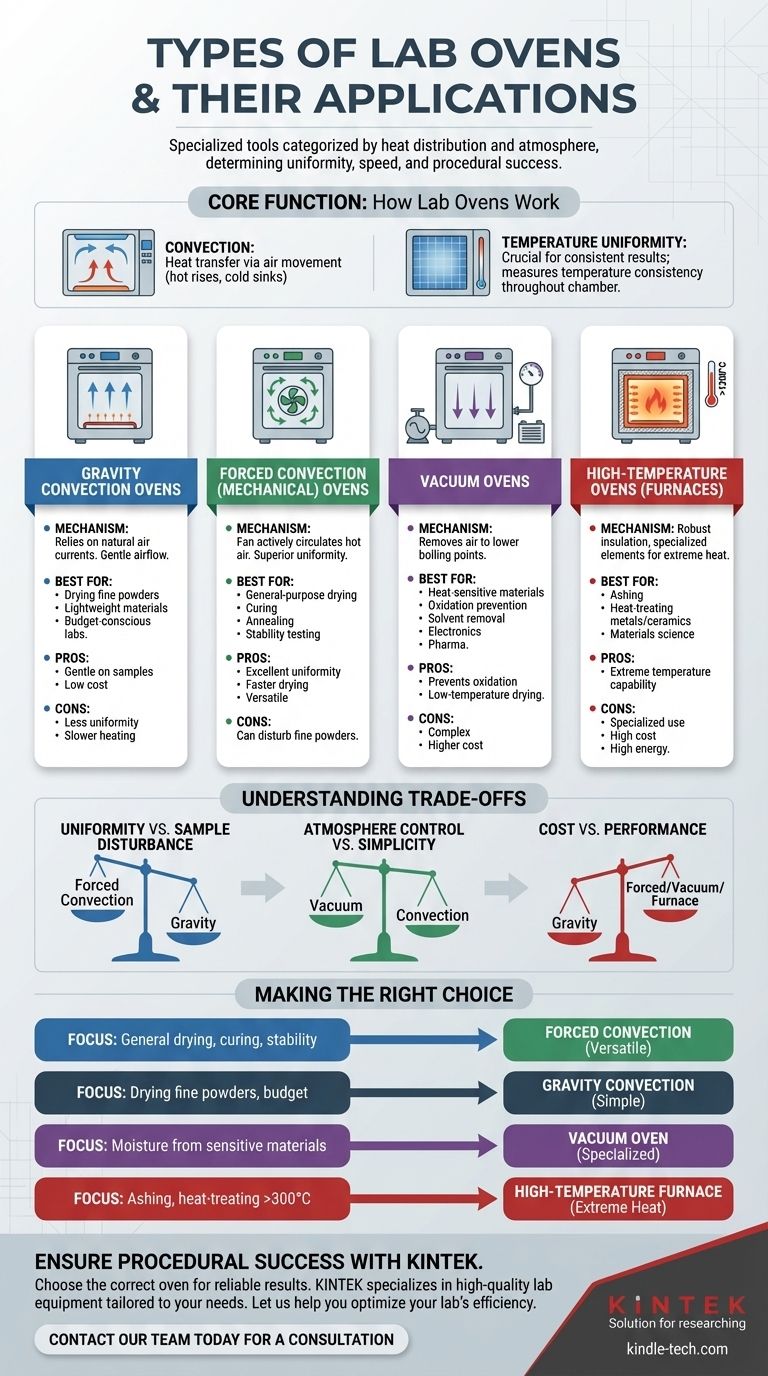

In a professional laboratory, ovens are not one-size-fits-all appliances but are specialized tools categorized by their method of heat distribution and intended atmosphere. The primary types are gravity convection, forced convection (also called mechanical), vacuum, and high-temperature ovens, each engineered for distinct applications requiring different levels of temperature uniformity and control.

The critical distinction between laboratory ovens lies in how they manage airflow. This single factor determines temperature uniformity, drying speed, and suitability for specific sample types, making the choice between forced convection, gravity convection, or vacuum a defining decision for procedural success.

The Core Function: How Lab Ovens Work

A laboratory oven is an insulated chamber that uses a thermostat to control a heating element. While simple in principle, the method used to circulate this heat is what differentiates one type from another and dictates its proper use.

H3: The Role of Convection

Convection is the transfer of heat through the movement of a fluid, in this case, air. As air near the heating element gets hot, it becomes less dense and rises. Cooler, denser air sinks to take its place, creating a natural current that distributes heat throughout the chamber.

H3: The Importance of Temperature Uniformity

For many scientific applications, such as stability testing or material curing, it is crucial that every part of a sample experiences the exact same temperature. Temperature uniformity is a measure of how consistent the temperature is throughout the oven's chamber. Poor uniformity can lead to inconsistent and unreliable results.

Key Oven Types and Their Ideal Applications

Choosing the correct oven requires understanding how its design impacts your specific process, from simple glassware drying to delicate outgassing of electronics.

H3: Gravity Convection Ovens

These are the simplest type of lab oven. They rely entirely on natural air currents for heat distribution. The heating elements are typically located at the bottom of the chamber, causing warm air to rise and cooler air to sink.

This gentle airflow makes them ideal for drying fine powders or lightweight materials that could be disturbed by a fan. However, this process results in less temperature uniformity and slower heat-up and recovery times.

H3: Mechanical (Forced Convection) Ovens

A mechanical convection oven adds a fan or blower to actively circulate hot air throughout the chamber. This forced movement of air eliminates the hot and cold spots common in gravity ovens.

The result is superior temperature uniformity and significantly faster drying and heating. This makes forced convection ovens the versatile workhorse for the vast majority of lab applications, including annealing, stability testing, and most drying protocols.

H3: Vacuum Ovens

A vacuum oven allows for drying samples under reduced pressure. By removing air from the chamber with a vacuum pump, the boiling point of water and other solvents is significantly lowered.

This is essential for drying materials that are heat-sensitive, easily oxidized, or contain solvents that are difficult to remove at atmospheric pressure. They are critical for applications in electronics, pharmaceuticals, and medical device manufacturing to prevent oxidation and ensure complete moisture removal.

H3: High-Temperature Ovens (Furnaces)

While standard lab ovens typically operate up to around 300°C (572°F), some processes require much higher heat. High-temperature ovens, often called muffle furnaces, are built with more robust insulation and specialized heating elements to reach temperatures of 1,200°C or higher.

Their primary use is for demanding applications like ashing, heat-treating metals or ceramics, and advanced materials science research.

Understanding the Trade-offs

The best oven is not the most powerful one, but the one whose characteristics best match the requirements of your sample and procedure.

H3: Uniformity vs. Sample Disturbance

The primary trade-off is between gravity and forced convection. The fan in a forced convection oven provides excellent uniformity but can blow around fine powders or disturb delicate samples. For these specific cases, the gentle airflow of a gravity oven is superior, despite its slower performance.

H3: Atmosphere Control vs. Simplicity

A standard convection oven is simple to operate. A vacuum oven offers unparalleled control over the chamber's atmosphere, preventing oxidation and enabling low-temperature drying. However, this comes with the added complexity and cost of a vacuum pump and more intricate controls.

H3: Cost vs. Performance

Gravity convection ovens are the most affordable option due to their simple design. Forced convection ovens represent a moderate investment for their significant increase in performance and versatility. Vacuum and high-temperature ovens are specialized, high-cost instruments reserved for applications where their unique capabilities are essential.

Making the Right Choice for Your Application

Selecting the correct oven is a crucial step in ensuring the accuracy and repeatability of your work. Consider your primary goal to make a clear decision.

- If your primary focus is general-purpose drying, curing, or stability testing: A mechanical (forced convection) oven is the most versatile and reliable choice for consistent results.

- If your primary focus is drying fine powders or budget is the main constraint: A gravity convection oven provides a simple and cost-effective solution for non-critical applications.

- If your primary focus is removing moisture from oxygen-sensitive or heat-sensitive materials: A vacuum oven is the only appropriate tool for the job.

- If your primary focus is ashing, heat-treating metals, or testing materials above 300°C: You need a specialized high-temperature furnace, not a standard laboratory oven.

By matching the oven's core heating mechanism to your specific scientific needs, you ensure your equipment is an asset, not a variable, in your results.

Summary Table:

| Oven Type | Key Feature | Best For |

|---|---|---|

| Gravity Convection | Natural airflow, gentle heating | Drying fine powders, budget-friendly applications |

| Forced Convection | Fan-forced air, superior uniformity | General-purpose drying, curing, annealing, stability testing |

| Vacuum Oven | Reduced pressure, lowers boiling points | Heat-sensitive materials, oxidation prevention, solvent removal |

| High-Temperature | Extreme heat (up to 1200°C+) | Ashing, heat-treating metals/ceramics, materials science |

Ensure procedural success with the right lab oven from KINTEK.

Choosing the correct oven is critical for temperature uniformity, sample integrity, and reliable results. KINTEK specializes in high-quality laboratory equipment, including a full range of ovens tailored to diverse research and industrial needs. Our experts can help you select the perfect model for your application—whether you need the gentle drying of a gravity oven, the rapid uniformity of a forced convection model, the precise atmosphere control of a vacuum oven, or the extreme heat of a furnace.

Let us help you optimize your lab's efficiency and accuracy. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

- Large Vertical Graphite Vacuum Graphitization Furnace

People Also Ask

- Which type of furnace can create high temperature? Choose Between Tube and Box Furnaces

- What is the primary purpose of using vacuum-sealed quartz tubes? Ensure High-Purity Battery Material Synthesis

- Why use quartz tubes and vacuum sealing for sulfide solid-state electrolytes? Ensure Purity & Stoichiometry

- What is the role of a HPHT tube furnace in HTGR simulation? Achieve Precise Nuclear Environment Replications

- What environmental conditions does a vacuum tube furnace provide for copper sintering? Ensure High-Purity Results