To achieve high temperatures for material processing, the primary options are specialized electric furnaces, most commonly tube furnaces and box furnaces. These are designed for applications like annealing, sintering, and melting, with some models capable of reaching temperatures as high as 1600 °C (2912 °F) or more, depending on their construction and heating elements.

Choosing the right high-temperature furnace is not just about hitting a peak temperature. The critical decision lies in matching the furnace’s design—its shape, atmosphere control, and processing scale—to the specific requirements of your material and process.

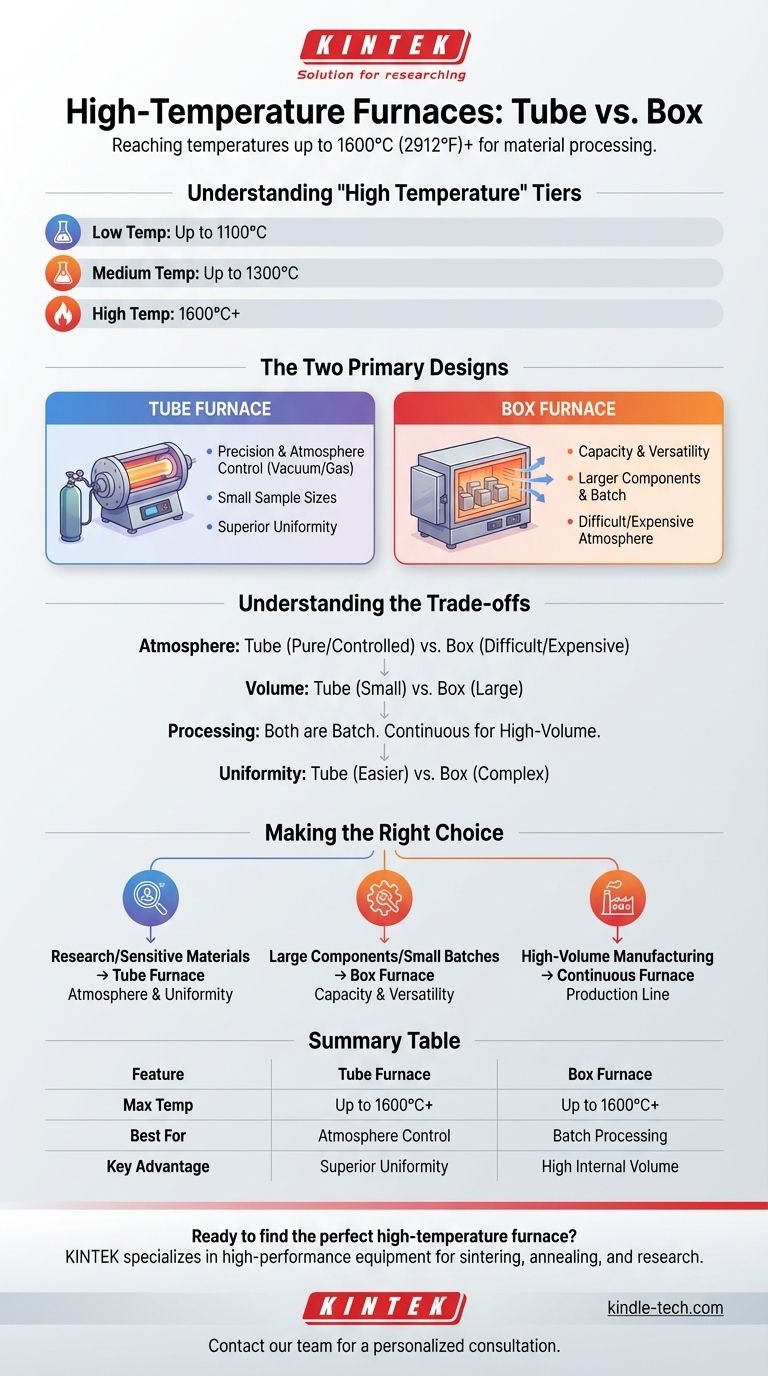

Understanding "High Temperature" in Furnaces

The term "high temperature" is relative, but in the context of laboratory and industrial furnaces, it follows a generally accepted classification. Understanding these tiers is the first step in selecting the correct equipment.

The Common Temperature Tiers

Most manufacturers categorize their furnaces by maximum operating temperature. While models vary, the tiers often look like this:

- Low Temperature: Up to 1100 °C (2012 °F)

- Medium Temperature: Up to 1300 °C (2372 °F)

- High Temperature: 1600 °C (2912 °F) and above

Furnaces in the "high temperature" category are required for demanding processes like sintering advanced ceramics or melting certain metals and alloys.

Why High Temperatures Are Necessary

The need for extreme heat is driven by the material's transformation point. Processes like sintering require high temperatures to bond powder particles into a solid mass without melting them, while annealing uses heat to relieve internal stresses in metals. Each application has a specific thermal profile that dictates the required furnace capability.

The Two Primary High-Temperature Furnace Designs

Beyond temperature, the most fundamental choice is between a tube and a box furnace. Their physical design dictates what they can do and how they do it.

The Tube Furnace: Precision and Atmosphere Control

A tube furnace uses a cylindrical ceramic tube surrounded by heating elements. The material to be heated is placed inside this tube.

This design is prized for its ability to create a highly uniform temperature zone and, most importantly, for enabling precise atmosphere control. The tube can be easily sealed, allowing it to be evacuated to a vacuum or filled with a specific gas (like argon or nitrogen) to prevent oxidation.

The Box Furnace: Capacity and Versatility

A box furnace, also known as a chamber or muffle furnace, has a rectangular chamber where materials are placed. Its design is simpler and offers a much larger internal volume.

This makes it the go-to choice for heat-treating larger components, multiple parts at once (batch processing), or processes like binder burnout where airflow and larger capacity are more important than a perfectly sealed atmosphere.

Understanding the Trade-offs

Selecting a furnace involves balancing competing priorities. The ideal choice for one application is often unsuitable for another.

Atmosphere vs. Volume

A tube furnace excels at creating a pure, controlled environment but is limited to smaller sample sizes that can fit within the tube's diameter.

A box furnace offers a large processing volume but makes achieving a high-purity vacuum or a perfectly controlled gas atmosphere significantly more difficult and expensive.

Batch vs. Continuous Processing

Most tube and box furnaces are batch furnaces. You load the material, run a heating cycle, and unload it. This is ideal for research, development, and low-volume production.

For medium- or high-volume manufacturing, a continuous furnace is used. Materials move through different heat zones on a conveyor belt, a fundamentally different design built for production lines.

Temperature Uniformity vs. Cost

Achieving excellent temperature uniformity—ensuring the entire sample is at the same temperature—is easier in the confined space of a tube furnace. While larger box furnaces can be designed for good uniformity, it often adds complexity and cost.

Making the Right Choice for Your Application

Your final decision should be guided by the primary goal of your heat treatment process.

- If your primary focus is research or processing sensitive materials: Choose a tube furnace for its superior atmosphere control and temperature uniformity.

- If your primary focus is heat-treating larger components or running small production batches: A box furnace provides the necessary capacity and versatility.

- If your primary focus is high-volume, automated manufacturing: You must look beyond standard batch equipment and investigate custom or continuous furnace systems.

Ultimately, defining your core requirements for atmosphere, volume, and scale will lead you to the correct furnace far more effectively than focusing on temperature alone.

Summary Table:

| Feature | Tube Furnace | Box Furnace |

|---|---|---|

| Max Temperature | Up to 1600°C+ | Up to 1600°C+ |

| Best For | Precise atmosphere control (vacuum, gas) | Batch processing, larger components |

| Key Advantage | Superior temperature uniformity | High internal volume & versatility |

Ready to find the perfect high-temperature furnace for your lab?

KINTEK specializes in high-performance lab equipment, including tube and box furnaces designed for demanding applications like sintering, annealing, and material research. Our experts can help you select the right furnace based on your specific requirements for temperature, atmosphere, and capacity.

Contact our team today for a personalized consultation and discover how KINTEK can enhance your laboratory's capabilities.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- Vertical Laboratory Tube Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the functions of a vacuum high-temperature furnace? Master Diffusion Bonding for Titanium Alloys

- What is plasma torch gasification as a method to dispose hazardous waste? Convert Hazardous Waste into Clean Energy & Inert Slag

- How does the drying step in a laboratory oven affect the quality of Fe@C nanotubes? Optimize Your Nanomaterial Synthesis

- What type of furnace is most efficient? Find the Best Heating Solution for Your Home and Budget

- How are pyrolysis reactors heated? Choosing the Right Method for Your Process

- What is the temperature range required for pyrolysis? A Guide to Optimizing Biochar, Bio-Oil, and Syngas

- What are the methods used in leak hunting in the vacuum system? Find & Fix Leaks Efficiently

- What is the primary role of vacuum heating equipment in halide solid electrolyte synthesis? Achieve High Conductivity