The fundamental reason to use a vacuum furnace is to achieve absolute control over the heat-treating environment. By removing air and other gases, a vacuum furnace eliminates the variables of oxidation and contamination, enabling metallurgical processes and material outcomes that are simply not possible in a traditional atmospheric furnace.

A vacuum furnace is not just a tool for heating; it is a precision instrument for material transformation. Its core purpose is to create an ultra-clean, highly controlled environment that protects parts from unwanted reactions, ensuring the highest possible quality, purity, and repeatability in the final product.

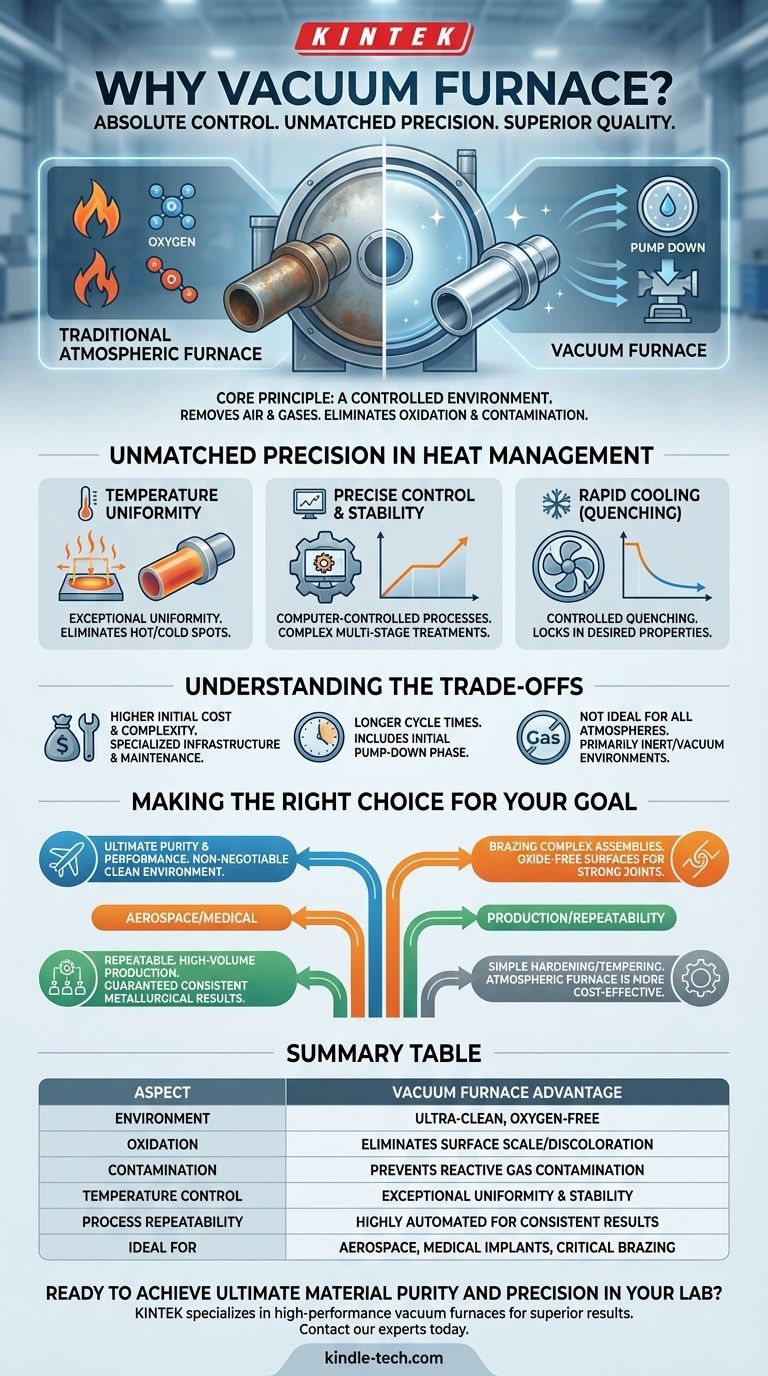

The Core Principle: A Controlled Environment

The primary advantage of a vacuum furnace stems from creating a near-perfect void. Removing the atmosphere fundamentally changes how heat treatment works.

Preventing Oxidation and Contamination

In a standard furnace, the oxygen in the air reacts with hot metal, creating an oxide layer (scale) on the surface. A vacuum furnace removes virtually all the air, preventing this oxidation.

This process ensures components emerge from the furnace bright and clean, free from discoloration. It also prevents contamination from reactive gases that could compromise the material's integrity.

Removing Byproducts and Impurities

The vacuum system doesn't just prevent contaminants from entering; it actively pulls unwanted byproducts away from the material during heating.

This "vacuuming" effect removes surface impurities and entrapped gases released during the process, resulting in a finished product with higher purity and superior quality.

Unmatched Precision in Heat Management

Removing air also allows for more precise and uniform control over temperature, a critical factor in achieving specific material properties.

Achieving Temperature Uniformity

Without air, heat is transferred primarily through radiation, not convection. This results in exceptionally uniform temperature distribution across the part and throughout the furnace chamber.

This uniformity eliminates hot and cold spots, ensuring that even complex geometries receive a consistent heat treatment for predictable results.

Enabling Precise Control and Stability

Modern vacuum furnaces are highly automated. Computer-controlled processes manage the entire cycle, from initial pump-down to heating ramps, soak times, and cooling.

This level of precision allows for complex, multi-stage heat treatments to be executed perfectly every time, ensuring metallurgical repeatability from one batch to the next.

Facilitating Rapid Cooling (Quenching)

Many vacuum furnaces are equipped with systems that can rapidly introduce inert gas to cool the product quickly. This controlled quenching is crucial for "locking in" desired properties like hardness.

This process shortens the overall cycle time and provides another layer of control over the final structure of the material.

Understanding the Trade-offs

While powerful, a vacuum furnace is not the universal solution for all heating applications. Objectivity requires acknowledging its specific limitations.

Higher Initial Cost and Complexity

Vacuum furnaces represent a significant capital investment compared to their atmospheric counterparts. They also require more specialized infrastructure, such as powerful vacuum pumps, and more rigorous maintenance.

Longer Overall Cycle Times

The initial pump-down phase—the time it takes to remove the air and achieve the desired vacuum level—can add significant time to the overall process cycle.

Not Ideal for All Atmospheres

Some heat treatment processes, such as gas carburizing, intentionally introduce a specific reactive atmosphere. While partial-pressure gas processes are possible in vacuum furnaces, they are primarily designed for inert or vacuum environments.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace depends entirely on the required outcome for your components.

- If your primary focus is ultimate material purity and performance (e.g., for aerospace or medical implants): The clean, non-reactive environment of a vacuum furnace is non-negotiable.

- If your primary focus is brazing complex assemblies or dissimilar metals: The oxide-free surface created in a vacuum is essential for achieving strong, clean, and reliable brazed joints.

- If your primary focus is repeatable, high-volume production of critical parts: The computer-controlled precision of a vacuum furnace minimizes defects and guarantees consistent metallurgical results.

- If your primary focus is simple hardening or tempering of non-critical components: A less expensive and faster atmospheric furnace is often the more practical and cost-effective choice.

Ultimately, choosing a vacuum furnace is an investment in process control, guaranteeing a level of quality and consistency that conventional furnaces cannot match.

Summary Table:

| Aspect | Vacuum Furnace Advantage |

|---|---|

| Environment | Ultra-clean, oxygen-free atmosphere |

| Oxidation | Eliminates surface scale and discoloration |

| Contamination | Prevents reactive gas contamination |

| Temperature Control | Exceptional uniformity and stability |

| Process Repeatability | Highly automated for consistent results |

| Ideal For | Aerospace, medical implants, critical brazing |

Ready to achieve ultimate material purity and precision in your lab?

KINTEK specializes in high-performance vacuum furnaces designed for laboratories that demand the highest levels of quality and repeatability. Whether you are working on aerospace components, medical implants, or complex brazing applications, our equipment ensures a contamination-free environment for superior results.

Contact our experts today to find the perfect vacuum furnace solution for your specific needs and elevate your material transformation processes.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does the co-sintering process improve bulk-type ASSBs? Optimize Interfaces with Advanced High-Temperature Furnaces

- What is sintering in a furnace? A Guide to Creating Strong, Dense Parts from Powder

- What is debinding in 3D printing? The Essential Step for Strong Metal & Ceramic Parts

- What are the advantages of brazing? Achieve Superior Joint Integrity for Complex Assemblies

- What is the temperature limit for brazing? Find Your Brazing Temperature Window

- How does heat affect tensile strength? Understand the Strength-Ductility Trade-Off

- What equipment is used in annealing? Selecting the Right Furnace for Your Process

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing