In short, the primary disadvantages of a coreless induction furnace are its relatively low power efficiency and its complete lack of refining capability. While it offers excellent process control and flexibility, it demands high-quality charge materials and consumes more energy per ton of metal compared to alternatives like channel furnaces.

A coreless induction furnace prioritizes operational flexibility over raw efficiency. Its design makes it ideal for melting a wide variety of alloys but requires significant investment in infrastructure and imposes strict demands on the quality of your raw materials.

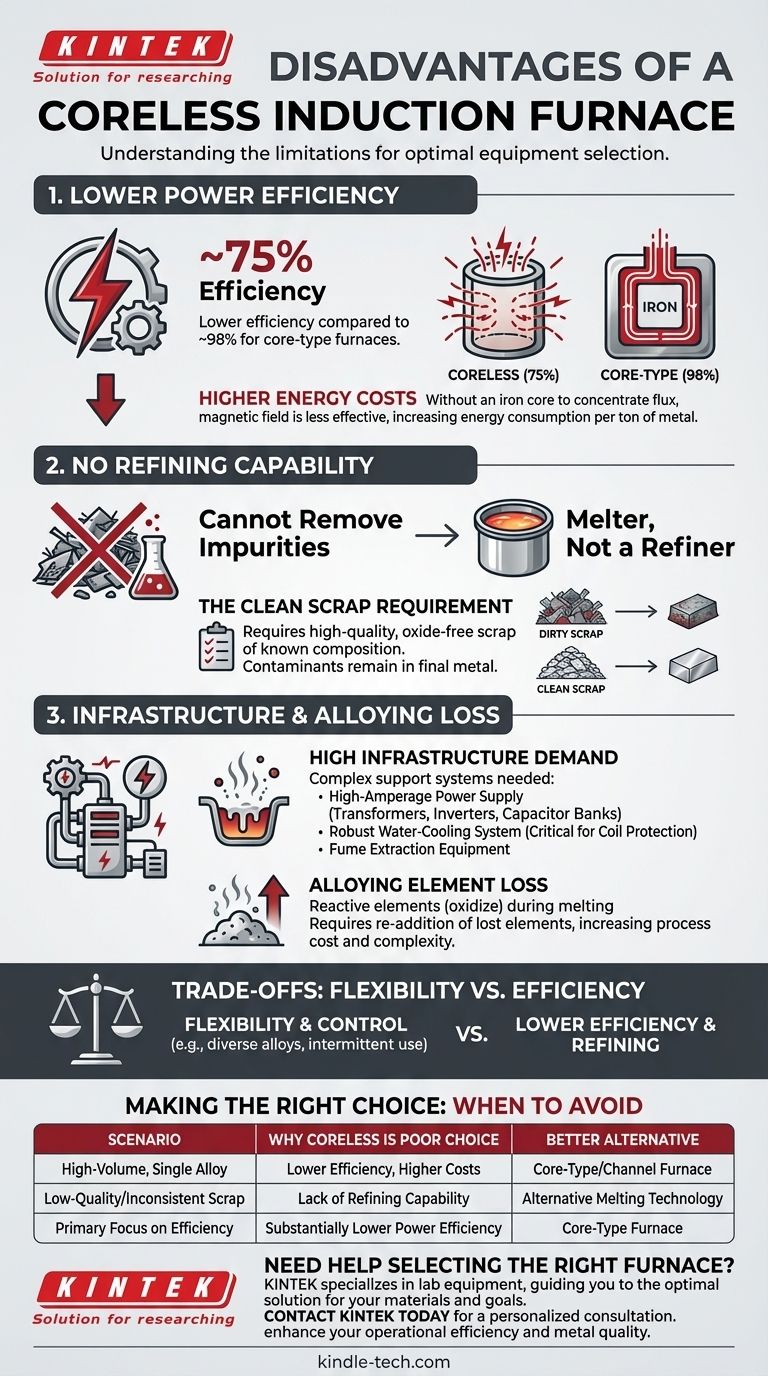

The Challenge of Power Efficiency

One of the most significant drawbacks of a coreless furnace is its energy consumption. The design is inherently less efficient than furnaces that utilize an iron core to guide the magnetic field.

Understanding the Energy Loss

A coreless furnace works by passing a powerful alternating current through a copper coil, which induces eddy currents directly into the metal charge, generating heat. Without a central iron core to concentrate and direct the magnetic flux, a portion of the magnetic field does not couple with the metal, resulting in lower efficiency.

The Efficiency Numbers

This design typically results in a power efficiency of around 75%. While effective, this is substantially lower than a core-type induction furnace, which can achieve efficiencies as high as 98% by using an iron core to create a closed magnetic loop, similar to a transformer.

The Inability to Refine Materials

A coreless induction furnace is a melter, not a refiner. This is a critical limitation that dictates its entire operational workflow and material sourcing strategy.

The "Clean Scrap" Requirement

The charge materials must be free of oxides and of a known composition. The furnace cannot remove impurities like excess carbon, phosphorus, or sulfur. Any contaminants present in the raw materials will remain in the final molten metal, compromising its quality.

Loss of Alloying Elements

During the melting process, some valuable and reactive alloying elements can be lost due to oxidation. These elements must then be measured and re-added to the melt to meet the final chemical specification, which adds cost and complexity to the process.

Understanding the Trade-offs: Flexibility vs. Efficiency

The disadvantages of a coreless furnace are best understood as trade-offs for its primary advantages: flexibility and control.

Why You Would Choose a Coreless Furnace

These furnaces excel in environments that require melting various grades of steel, iron, and non-ferrous alloys. They can be started and stopped relatively easily, making them ideal for foundries with intermittent production schedules or diverse product lines. The vigorous stirring action, influenced by power and frequency, also ensures excellent temperature and chemical homogeneity in the melt.

The Cost of Complexity

This flexibility comes with operational demands. A coreless furnace requires a complex support system, including:

- A dedicated high-amperage power supply with transformers, inverters, and capacitor banks to deliver the correct frequency.

- A robust water-cooling system to protect the copper coil from overheating, a critical point of failure.

- Fume extraction equipment to manage the off-gasses generated during melting.

Making the Right Choice for Your Operation

Choosing the correct furnace technology depends entirely on your specific production goals and operational constraints.

- If your primary focus is high-volume, continuous production of a single alloy: A core-type or channel furnace is likely more cost-effective due to its superior power efficiency.

- If your primary focus is melting diverse alloys or operating intermittently: The flexibility of a coreless furnace often outweighs its lower energy efficiency and makes it the superior choice.

- If your raw material quality is low or inconsistent: A coreless induction furnace is a poor choice due to its lack of refining capability, and a different melting technology may be required.

Understanding these inherent limitations ensures you select a furnace that aligns with your operational reality, not just your melting needs.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Lower Power Efficiency | ~75% efficiency vs. 98% for core-type furnaces, leading to higher energy costs per ton of metal. |

| No Refining Capability | Cannot remove impurities; requires high-quality, clean scrap of known composition. |

| Alloying Element Loss | Reactive elements can oxidize during melting, requiring re-addition and increasing cost. |

| High Infrastructure Demand | Needs complex support systems like high-power electrical supplies and water-cooling. |

Need help selecting the right furnace for your lab or foundry?

At KINTEK, we specialize in lab equipment and consumables, helping you navigate the trade-offs between furnace technologies. Whether you require the flexibility of a coreless furnace or the efficiency of a core-type system for your laboratory melting applications, our experts can guide you to the optimal solution for your specific materials and production goals.

Contact KINTEK today for a personalized consultation and discover how the right equipment can enhance your operational efficiency and metal quality.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys