While hardening steel is a foundational process for increasing strength and wear resistance, it is not a free lunch in metallurgical terms. The primary disadvantage is that the dramatic increase in hardness comes at the direct cost of the material's toughness, making it significantly more brittle and susceptible to fracture under impact or shock loading.

The core trade-off of hardening steel is simple: you are exchanging ductility and toughness for hardness and strength. This introduces risks like cracking and distortion, which must be carefully managed through process control and secondary treatments like tempering.

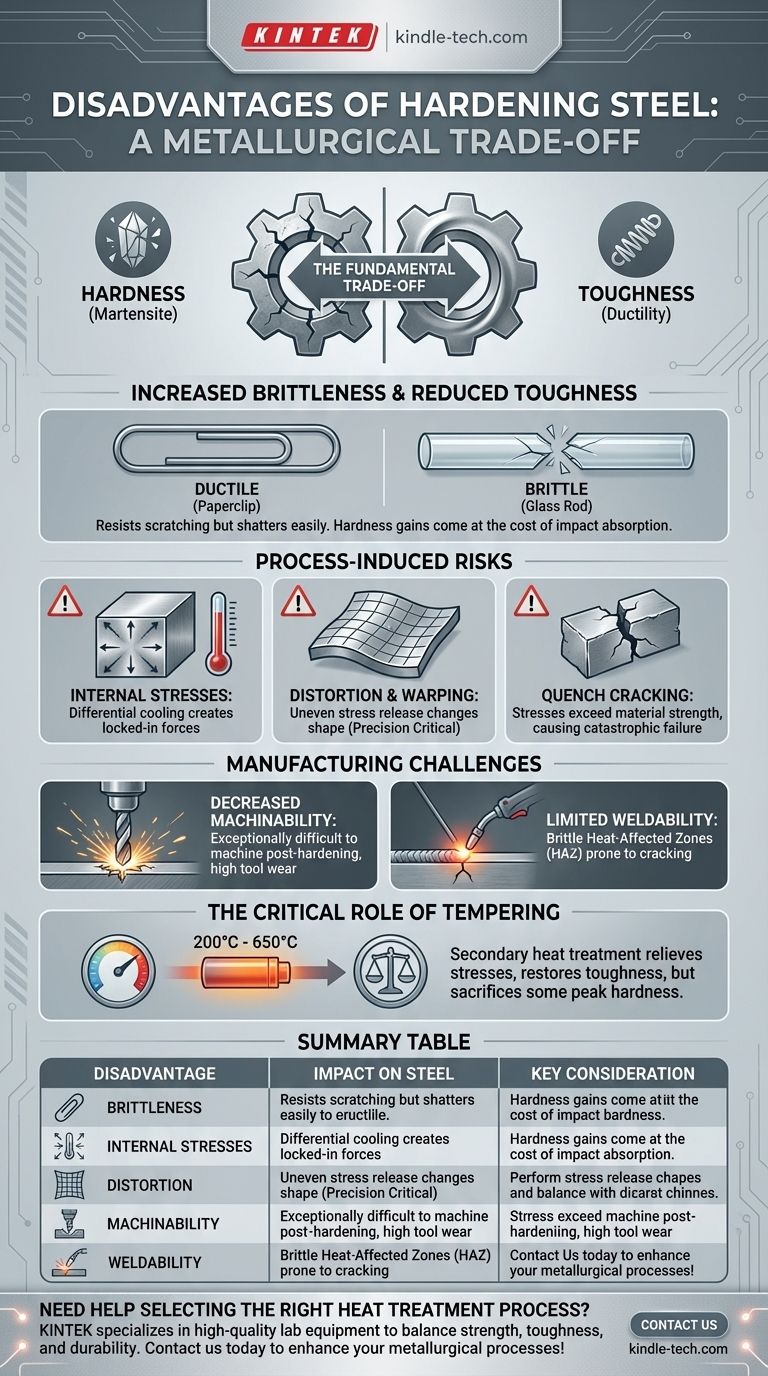

The Fundamental Trade-off: Hardness vs. Toughness

Hardening transforms the steel's internal crystal structure into martensite, a configuration that is extremely hard but inherently brittle. This creates a material with a new set of properties and limitations.

The Increase in Brittleness

Hardened, untempered steel behaves more like a ceramic than a typical metal. It resists scratching and deformation, but it has very little ability to bend or stretch before it shatters.

Think of a paperclip versus a glass rod. You can bend the ductile paperclip multiple times, but the brittle glass rod will snap cleanly with very little bending. Hardening pushes steel far towards the behavior of the glass rod.

Reduced Toughness and Ductility

Toughness is a material's ability to absorb energy and deform without fracturing. Ductility is its ability to be stretched or drawn out.

The martensitic structure created during hardening severely restricts the movement of atoms within the steel's crystal lattice. This is what makes it hard, but it also prevents the material from absorbing impact energy, leading to low toughness.

Process-Induced Risks and Challenges

The hardening process itself—rapidly cooling the steel from over 900°C—is aggressive and introduces significant risk to the component.

Introduction of Internal Stresses

During quenching, the outside surface of the steel part cools and contracts much faster than the core. This differential creates immense internal stresses that become locked into the material.

These residual stresses can act as pre-loaded weak points, contributing to premature failure in service, even under loads that are below the material's expected strength limit.

Risk of Distortion and Warping

As internal stresses build and release unevenly during the quench, the part can physically change shape. This distortion or warping can be a critical failure, especially for precision components that must meet tight dimensional tolerances.

Long, thin parts or components with complex geometries are particularly susceptible to this issue.

Potential for Quench Cracking

This is the most catastrophic failure mode of the hardening process. If the internal stresses generated during quenching exceed the steel's ultimate tensile strength, the part will simply crack.

Sharp internal corners, sudden changes in thickness, and overly aggressive quenching mediums (like brine or water) significantly increase the risk of quench cracking.

Understanding the Key Trade-offs

Choosing to harden a component requires you to balance its benefits against its inherent drawbacks and manufacturing complexities.

The Critical Role of Tempering

Virtually no steel component is used in its fully hardened state due to extreme brittleness. A secondary heat treatment called tempering is almost always required.

Tempering involves reheating the hardened part to a much lower temperature (e.g., 200°C - 650°C) to relieve internal stresses and restore a degree of toughness. However, this process also reduces the peak hardness achieved during quenching. The higher the tempering temperature, the tougher but less hard the steel becomes.

Decreased Machinability

Hardened steel is exceptionally difficult and expensive to machine. Its high wear resistance works against cutting tools.

For this reason, all major machining operations like milling, drilling, and turning are typically completed before the heat treatment process. Any machining required after hardening, such as for correcting distortion, must be done with slower and more costly processes like grinding or electrical discharge machining (EDM).

Limited Weldability

Welding a fully hardened part is highly problematic. The intense, localized heat of the arc creates a new, brittle heat-affected zone (HAZ) that is extremely prone to cracking as it cools.

Successfully welding hardened materials requires specialized procedures, including pre-heating and post-weld heat treatments, which add significant complexity and cost to fabrication.

Making the Right Choice for Your Application

Understanding these disadvantages is key to using heat treatment effectively. Your decision should be guided by the primary requirement of the component.

- If your primary focus is maximum wear resistance: Harden the steel to its highest potential and plan for post-process grinding to achieve final dimensions, accepting the lower toughness.

- If your primary focus is impact resistance and durability: Use a hardening and tempering cycle, sacrificing some peak hardness to gain the necessary toughness for the application.

- If your primary focus is dimensional stability and ease of manufacturing: Machine the part to its final shape before hardening, and use a carefully controlled quench to minimize distortion, or consider a different material altogether.

By recognizing that hardness is gained at the expense of other key properties, you can engineer a component that possesses the precise balance of characteristics required to succeed.

Summary Table:

| Disadvantage | Impact on Steel | Key Consideration |

|---|---|---|

| Increased Brittleness | Reduced toughness and impact resistance | High risk of fracture under shock loading |

| Internal Stresses | Risk of cracking and premature failure | Requires controlled quenching and tempering |

| Distortion and Warping | Dimensional inaccuracies | Critical for precision components |

| Reduced Machinability | Difficult to machine post-hardening | Most machining must be done before heat treatment |

| Limited Weldability | High risk of cracking in heat-affected zones | Requires specialized welding procedures |

Need help selecting the right heat treatment process for your steel components? At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your laboratory's needs. Whether you're optimizing hardening cycles or balancing material properties, our expertise ensures you achieve the perfect balance of strength, toughness, and durability. Contact us today to discuss how our solutions can enhance your metallurgical processes and deliver reliable results!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What are the factors that affect the strength of a brazed joint? Master the 4 Keys to a Perfect Bond

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- What are the advantages of brazing compared to welding? Achieve Clean, Low-Distortion Metal Joining

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- Does brazing require heat? Yes, it's the catalyst for creating strong, permanent bonds.