The defining features of the Lead Dioxide-Titanium (PbO₂-Ti) Oxygen Evolution Electrode are its high oxidizing power, robust physical construction, and long operational life. This insoluble anode is built on a titanium mesh base with a double-plated PbO₂ coating, making it highly durable and resistant to corrosion in demanding electrochemical environments.

This electrode is engineered for applications requiring strong oxidation and high durability. Its primary trade-off is higher energy consumption at high current densities when compared to alternatives like Iridium-Tantalum anodes.

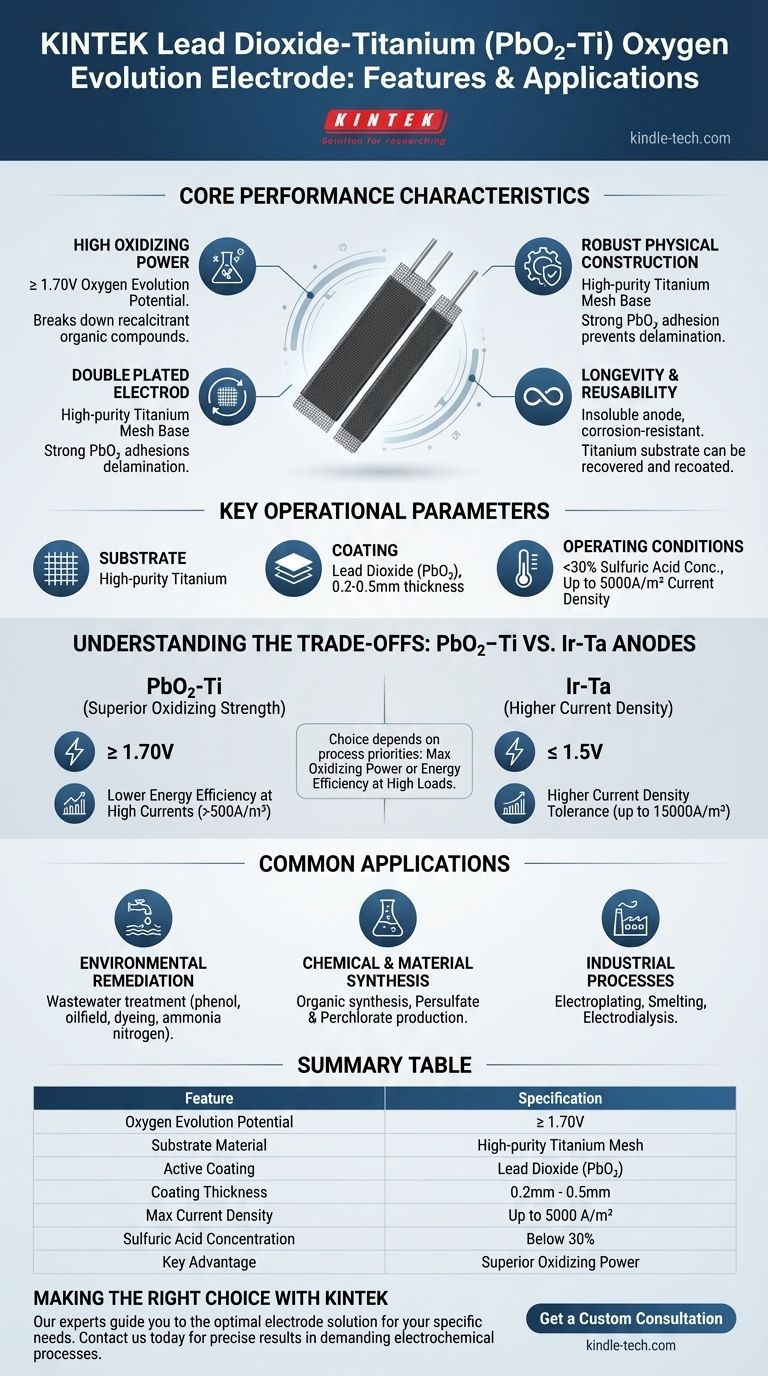

Core Performance Characteristics

The value of the PbO₂-Ti electrode stems from a specific combination of electrochemical and physical properties.

High Oxidizing Power

The electrode has an oxygen evolution potential of ≥ 1.70V. This high potential provides a very strong oxidizing capability, which is essential for breaking down recalcitrant organic compounds or driving specific electrosynthesis reactions that other anodes cannot.

Robust Physical Construction

Its base is a high-purity titanium mesh, which provides an excellent balance of conductivity and corrosion resistance. The design features a double-plated, three-dimensional structure that ensures strong adhesion of the PbO₂ coating, preventing delamination and extending the electrode's service life.

High Current Efficiency

At low current densities, its energy consumption is comparable to that of Iridium-Tantalum (Ir-Ta) anodes, making it an efficient choice for certain operational ranges. This allows for effective process control without excessive energy waste under the right conditions.

Longevity and Reusability

This is an insoluble anode, meaning it does not readily dissolve or contaminate the electrolyte during operation. It offers good corrosion resistance, and once the PbO₂ coating eventually degrades, the titanium substrate can be recovered and recoated, providing significant long-term value.

Key Operational Parameters

To be used effectively, the electrode must be operated within its specified limits.

Substrate and Coating

The substrate is a high-purity titanium mesh, which is then plated with Lead Dioxide (PbO₂). This active coating is what facilitates the electrochemical reactions.

Operating Conditions

This electrode is designed for use in environments with a sulfuric acid concentration below 30%. It can handle an applicable current density of up to 5000A/m².

Plating Thickness

The active PbO₂ coating is applied to a thickness of 0.2mm to 0.5mm, providing a substantial layer of catalytic material for a long operational lifespan.

Understanding the Trade-offs: PbO₂-Ti vs. Ir-Ta Anodes

No single electrode is perfect for every application. The choice between a PbO₂-Ti anode and a common alternative like an Iridium-Tantalum (Ir-Ta) anode depends entirely on your process priorities.

Oxidizing Potential

The PbO₂-Ti anode's oxygen evolution potential (≥ 1.70V) is significantly higher than that of an Ir-Ta anode (≤ 1.5V). This makes the PbO₂-Ti anode superior for tasks requiring the highest possible oxidizing strength.

Energy Consumption

While comparable at low currents, the PbO₂-Ti anode's energy consumption becomes a disadvantage at higher loads. Above 500A/m², its cell voltage is approximately 0.2V higher than an Ir-Ta cell, leading to greater energy costs.

Current Density Tolerance

Ir-Ta anodes can operate at much higher current densities (up to 15000A/m²) compared to the PbO₂-Ti anode's limit of 5000A/m². This gives Ir-Ta an advantage in processes demanding extremely high production rates.

Common Applications

The unique properties of the PbO₂-Ti anode make it suitable for a wide range of demanding industrial and environmental processes.

Environmental Remediation

Its strong oxidizing power is highly effective for wastewater treatment, including the decolorization of phenol-containing wastewater, and the treatment of oilfield, printing, dyeing, and ammonia nitrogen wastewater.

Chemical and Material Synthesis

The anode is used in organic synthesis requiring high oxygen evolution potential, as well as the production of persulfate and perchlorate.

Industrial Processes

It is also applied in electroplating, smelting, and electrodialysis, where its stability and performance in complex media are highly valued.

Making the Right Choice for Your Process

Your specific goal determines which electrode characteristic is most important.

- If your primary focus is maximum oxidizing power for difficult-to-treat waste: The PbO₂-Ti anode's high oxygen evolution potential (≥ 1.70V) is its most critical advantage.

- If your primary focus is energy efficiency at high current densities (>500A/m²): An Iridium-Tantalum anode is likely the superior choice due to its lower cell voltage.

- If your primary focus is cost-effective durability in sulfate-heavy environments: The PbO₂-Ti anode's robust coating and reusable substrate make it a strong, long-term contender.

Ultimately, selecting the correct anode is about matching the tool to the specific demands of your electrochemical application.

Summary Table:

| Feature | Specification |

|---|---|

| Oxygen Evolution Potential | ≥ 1.70V |

| Substrate Material | High-purity Titanium Mesh |

| Active Coating | Lead Dioxide (PbO₂) |

| Coating Thickness | 0.2mm - 0.5mm |

| Max Current Density | Up to 5000 A/m² |

| Sulfuric Acid Concentration | Below 30% |

| Key Advantage | Superior Oxidizing Power |

Ready to select the right electrode for your demanding electrochemical process?

KINTEK specializes in high-performance lab equipment and consumables, including robust electrodes like the PbO₂-Ti anode. We help laboratories and industrial facilities achieve precise results in applications from wastewater remediation to chemical synthesis.

Our experts can guide you to the optimal solution based on your specific needs for oxidizing power, energy efficiency, and durability. Contact us today to discuss how our electrodes can enhance your process efficiency and reliability.

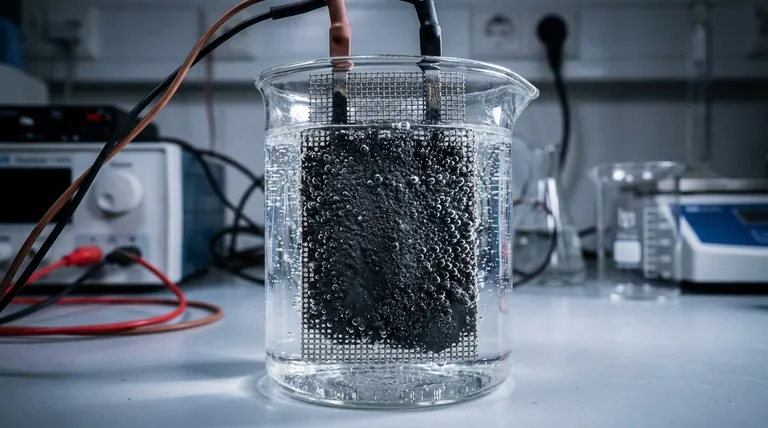

Visual Guide

Related Products

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Platinum Auxiliary Electrode for Laboratory Use

- Metal Disc Electrode Electrochemical Electrode

- Graphite Disc Rod and Sheet Electrode Electrochemical Graphite Electrode

People Also Ask

- How should a platinum wire/rod electrode be cleaned before use? A Guide to Reliable Electrochemical Data

- What is the common role of a platinum disk electrode? A Guide to Its Primary Use as a Working Electrode

- What are the performance characteristics of platinum wire/rod electrodes? Unmatched Stability for Your Lab

- What is the difference between ring disk electrode and rotating disk electrode? Unlock Deeper Electrochemical Insights

- What is the RRDE in electrochemistry? Unlock Detailed Reaction Pathways with Dual-Electrode Analysis