Properly loading an autoclave requires arranging items to ensure complete steam penetration while strictly avoiding materials that pose a safety risk. You must never load sealed containers, as they can explode under pressure, nor should you include solvents or waterproof materials like oils. Always leave adequate space between items and never overcrowd the chamber, as this is the most common cause of sterilization failure.

The effectiveness of an autoclave cycle is not determined by time or temperature alone, but by the ability of pressurized steam to make direct contact with every single surface. Your primary goal when loading is to create clear, unobstructed pathways for steam to circulate freely.

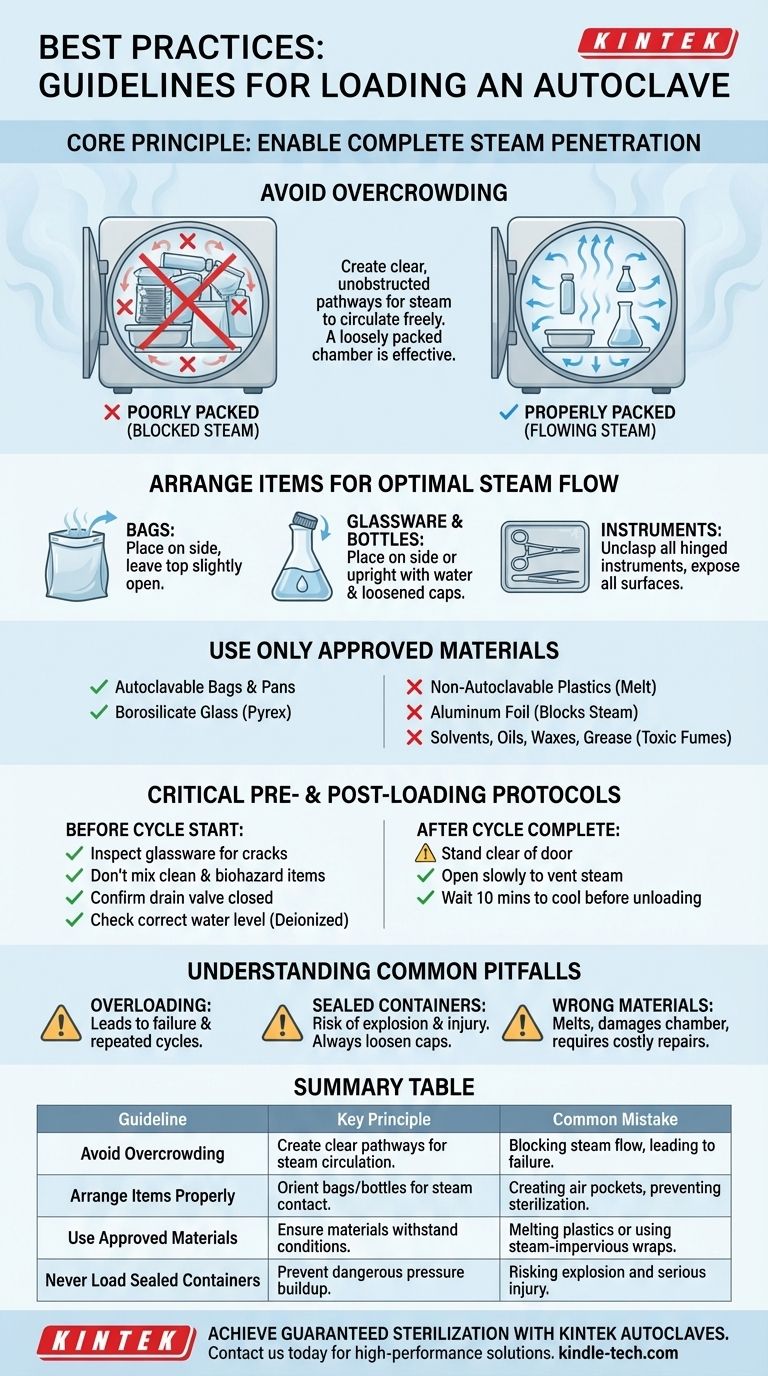

The Core Principle: Enabling Complete Steam Penetration

An autoclave sterilizes using high-pressure, high-temperature steam. If steam cannot touch a surface, that surface will not be sterilized. Every loading guideline is designed to facilitate this fundamental process.

Avoid Overcrowding the Chamber

The most common mistake operators make is overloading the autoclave to save time. This is counterproductive, as it blocks steam pathways and often results in an incomplete sterilization cycle that must be repeated.

Leave ample space between all items—whether they are instrument packs, bags, or glassware. A loosely packed chamber is an effective one.

Arrange Items for Optimal Steam Flow

The orientation of your items matters significantly.

- Bags: Place autoclavable biohazard bags on their side, leaving the top slightly open for steam to enter. Placing them upright can create air pockets that prevent sterilization.

- Glassware & Bottles: Place all flasks, beakers, and bottles on their side or, if upright, with a small amount of water at the bottom to help generate steam internally. Caps must be loosened to allow pressure to escape.

- Instruments: Unclasp all hinged instruments to expose all surfaces. Disperse individual instruments on a tray rather than piling them together.

Use Only Autoclave-Approved Materials

Using the wrong material can lead to failed sterilization, toxic fumes, or damage to the autoclave itself.

- Containers: Only use autoclavable bags and pans. Regular polyethylene plastic trays will melt, creating a costly and difficult mess to clean.

- Wraps: Never wrap items in aluminum foil. It is impervious to steam and will completely block sterilization for the items it covers.

- Liquids: Do not autoclave solvents, oils, waxes, or grease. Solvents can release toxic fumes, and waterproof substances cannot be penetrated by steam.

Critical Pre-Loading and Post-Loading Protocols

Proper operation extends beyond just loading the items. Following a strict protocol before and after the cycle is essential for safety and effectiveness.

Before Starting the Cycle

First, inspect all glassware for any cracks that could shatter under pressure. Ensure you are not mixing clean items with biohazardous waste in the same cycle to prevent cross-contamination.

Before sealing the door, confirm the autoclave's drain valve is fully closed and that the chamber has been filled with the correct type of water (typically deionized) to the proper level indicator line.

After the Cycle is Complete

The period immediately after a cycle is high-risk. Ensure no one is standing directly in front of the door.

Open the door slowly and only slightly at first, allowing the trapped, high-pressure steam to vent safely. Wait at least 10 minutes for the steam to dissipate and the items to cool before fully opening the door and removing your load.

Understanding the Common Pitfalls

Avoiding common mistakes is critical for maintaining a safe and efficient workflow. These errors can compromise safety, waste time, and damage expensive equipment.

The Myth of "Saving Time" by Overloading

The temptation to cram as much as possible into one cycle is strong, but it almost always leads to failure. An item that is not fully sterilized must be re-processed, doubling the time and resources used. A properly loaded chamber is always faster in the long run.

The Danger of Sealed Containers

This cannot be overstated. Heating a liquid in a sealed, airtight container creates immense pressure, effectively turning the container into a bomb. The resulting explosion can destroy the contents, damage the autoclave, and cause serious injury. Always loosen caps.

Damaging the Autoclave with Incorrect Materials

Using non-autoclavable plastic trays or bags is a frequent and costly mistake. These materials melt and can fuse to the chamber's interior, requiring extensive downtime and expensive professional repairs. Always verify your materials are rated for autoclave temperatures and pressures.

Making the Right Choice for Your Load

Your loading strategy should adapt slightly based on the material you are processing.

- If your primary focus is sterilizing laboratory instruments: Ensure instruments are open and arranged in a single layer within a sterilization pouch or on a tray to guarantee steam contact with all surfaces.

- If your primary focus is decontaminating biohazardous waste: Use a vented, autoclavable bag placed within a secondary, shallow autoclave-safe pan to contain any potential leaks during the cycle.

- If your primary focus is sterilizing liquids or media: Use vented caps on borosilicate (Pyrex) bottles and never fill them more than two-thirds full to prevent the liquid from boiling over.

Proper loading transforms the autoclave from a simple machine into a guaranteed tool for safety and sterility.

Summary Table:

| Guideline | Key Principle | Common Mistake to Avoid |

|---|---|---|

| Avoid Overcrowding | Create clear pathways for steam circulation. | Blocking steam flow, leading to sterilization failure. |

| Arrange Items Properly | Orient bags on their side; loosen caps on bottles. | Creating air pockets that prevent steam contact. |

| Use Approved Materials | Ensure materials can withstand autoclave conditions. | Melting plastics or using steam-impervious wraps like foil. |

| Never Load Sealed Containers | Prevent dangerous pressure buildup and explosions. | Risking equipment damage and serious injury. |

Achieve Guaranteed Sterilization with KINTEK Autoclaves

Proper loading is critical, but it starts with reliable equipment. KINTEK specializes in high-performance laboratory autoclaves and consumables designed for safety, efficiency, and ease of use.

Let our experts help you select the right autoclave and accessories for sterilizing instruments, decontaminating waste, or preparing media. We ensure your lab operates at peak safety and efficiency.

Contact us today to discuss your laboratory's specific needs and discover the KINTEK difference. Get in Touch Now

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What role does a PTFE-lined autoclave play in UIO-66 synthesis? Key Benefits for Pure MOF Nanocrystals

- What are the advantages of autoclave for sterilization? Achieve Unmatched Sterility with Steam and Pressure

- What is the autoclaving process in microbiology? Ensure Sterile Results and Lab Safety

- What lab supplies should be autoclaved? A Guide to Safe Sterilization and Decontamination

- What is important about loading an autoclave? Achieve Reliable Sterilization with Proper Technique

- What is the function of autoclaves in self-healing cement? Ensure Pure MICP for Superior Biomineralization

- Why are autoclave parameters 121°C for 15 minutes? The Science of Sterilizing Bacterial Spores

- What materials are used in sterilization? Match the Right Method to Your Lab Equipment