Effective heat treatment safety is a systematic process that combines the right personal protective equipment (PPE) with rigorous operational procedures and a deep understanding of the multiple hazards involved. The most critical precautions include using specialized heat-resistant gear, ensuring adequate ventilation for furnace atmospheres, strictly following lockout/tagout procedures during maintenance, and maintaining a constant awareness of both radiant heat and the risks associated with quenching mediums.

The core of heat treatment safety isn't just a checklist of gear; it's a culture of awareness. It requires recognizing that the most severe risks—such as atmospheric hazards or sudden equipment failure—are often invisible, demanding constant vigilance and adherence to proven procedures.

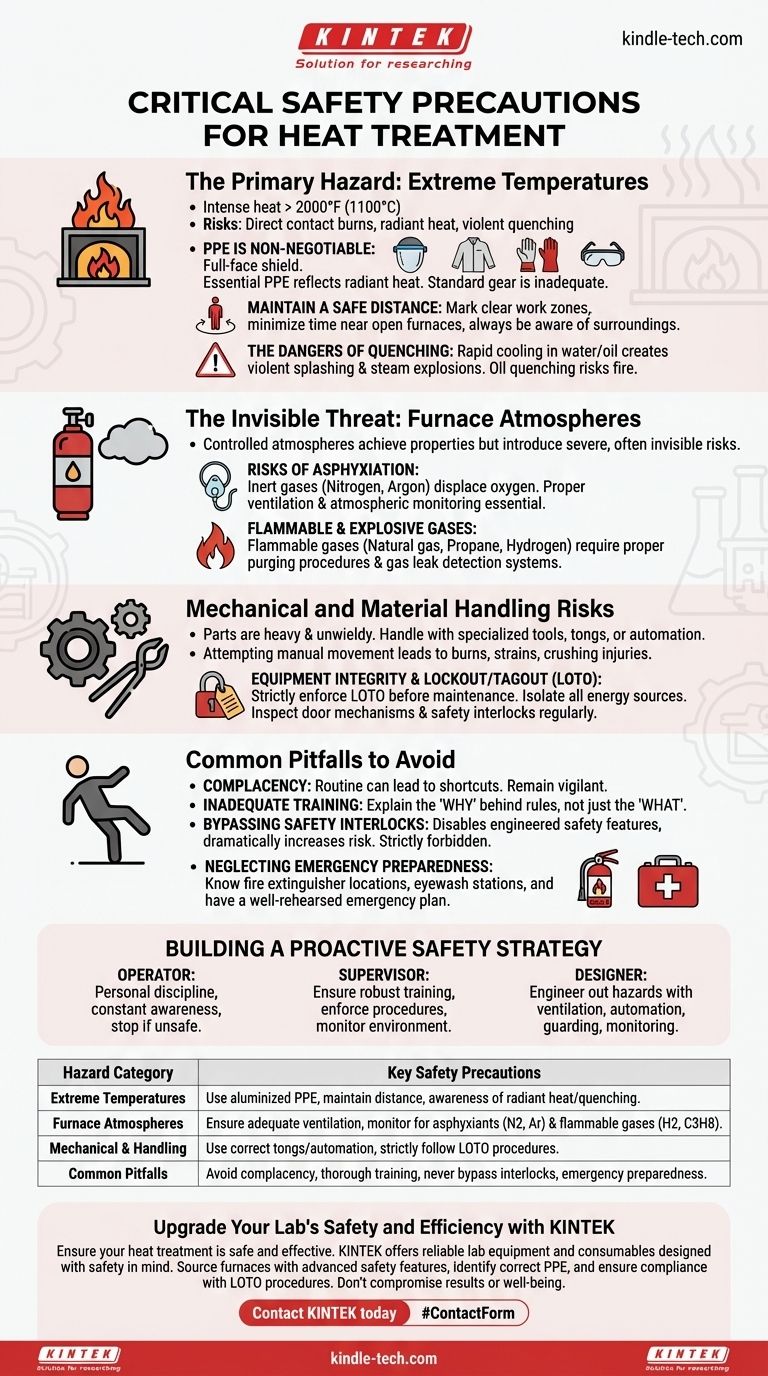

The Primary Hazard: Extreme Temperatures

The most obvious danger in heat treatment is the intense heat from furnaces, which can exceed 2000°F (1100°C). This heat presents risks of direct contact burns, radiant heat exposure, and violent reactions from quenching.

Personal Protective Equipment (PPE) is Non-Negotiable

Your first line of defense is specialized gear designed for high-temperature industrial environments. Standard work gloves or glasses are wholly inadequate.

Essential PPE includes aluminized or other heat-resistant jackets and pants, which reflect radiant heat. You must also use high-temperature gloves, safety glasses, and a full-face shield, especially when loading, unloading, or observing the furnace.

Maintaining a Safe Distance and Awareness

Radiant heat can cause severe burns and heat stress even without direct contact. It's crucial to establish and mark clear work zones around furnaces.

Minimize your time in the immediate vicinity of an open furnace door. Always be aware of your position and the position of others to avoid accidental contact with hot surfaces or parts.

The Dangers of Quenching

Quenching, the rapid cooling of a part, is one of the most hazardous steps. Dropping a hot part into a liquid like water or oil creates an immediate and violent reaction.

This can cause dangerous splashing and steam explosions. Quenching in oil presents an additional, significant fire risk if the oil's flash point is exceeded or if hot material is exposed to air improperly.

The Invisible Threat: Furnace Atmospheres

Many heat treatment processes use controlled atmospheres to achieve specific metallurgical properties. These gases introduce severe, often invisible, risks.

Risks of Asphyxiation

Inert gases like nitrogen and argon are commonly used to displace oxygen and prevent oxidation. While not toxic, they are simple asphyxiants.

A leak in an enclosed space can displace breathable air, leading to disorientation, collapse, and death in minutes. Proper ventilation and atmospheric monitoring are essential.

Flammable and Explosive Gases

Processes like carburizing use atmospheres containing flammable gases such as natural gas, propane, or hydrogen. These create a risk of fire or explosion if not handled correctly.

Proper purging procedures are critical to ensure that flammable mixtures are not present when the furnace is heated to its ignition temperature. Gas leak detection systems are a mandatory safety feature.

Mechanical and Material Handling Risks

The physical equipment and the parts being treated present their own set of significant hazards.

Safe Loading and Unloading

Parts being heat-treated are often heavy and unwieldy. Handling them at high temperatures requires specialized tools, tongs, or automated systems.

Attempting to manually move hot or heavy components is a primary cause of burns, strains, and crushing injuries. Always use the correct material handling equipment and ensure it is in good working order.

Equipment Integrity and Lockout/Tagout (LOTO)

Furnaces are complex machines with electrical, gas, and mechanical systems. An unexpected startup during maintenance can be catastrophic.

Lockout/Tagout (LOTO) procedures must be strictly enforced before any service work begins. This ensures all energy sources are isolated and cannot be re-energized until the work is completed safely. Regular inspection of door mechanisms, gas lines, and safety interlocks is also critical.

Common Pitfalls to Avoid

Even with the best equipment and procedures, safety failures often stem from human factors. Recognizing these pitfalls is key to building a resilient safety culture.

Complacency with Routine Tasks

The repetitive nature of heat treatment can lead to complacency. Operators may begin to take shortcuts or neglect a step in their PPE simply because "nothing has ever happened before." This is often when accidents occur.

Inadequate Training

Simply showing someone what to do is not enough. Effective training explains the "why" behind each safety rule—what happens if a purge cycle is skipped, or why a specific type of glove is required.

Bypassing Safety Interlocks

In a misguided attempt to save time, personnel may be tempted to bypass door switches or other safety interlocks. This disables engineered safety features and dramatically increases risk. This practice should be strictly forbidden.

Neglecting Emergency Preparedness

Every facility must have a clear, well-rehearsed emergency plan. This includes knowing the location and proper use of fire extinguishers (especially Class B for oil fires), eyewash stations, and first-aid kits. Personnel must be trained in responding to burns and other potential injuries.

Building a Proactive Safety Strategy

Your approach to safety should be tailored to your specific role within the operation.

- If you are an operator: Your focus must be on personal discipline, constant situational awareness, and never hesitating to stop a job if you feel it is unsafe.

- If you are a supervisor: Your role is to ensure robust training, enforce all procedures without exception, and actively monitor the work environment for developing hazards.

- If you are designing a new facility: Your priority is to engineer out hazards from the start with proper ventilation, automation, guarding, and state-of-the-art monitoring systems.

Ultimately, safety in heat treatment is an active, continuous process, not a passive state.

Summary Table:

| Hazard Category | Key Safety Precautions |

|---|---|

| Extreme Temperatures | Use aluminized heat-resistant PPE, maintain safe distance, be aware of radiant heat and quenching dangers. |

| Furnace Atmospheres | Ensure adequate ventilation, monitor for asphyxiants (nitrogen, argon), and flammable gases (hydrogen, propane). |

| Mechanical & Handling | Use correct tongs/automation for loading/unloading, strictly follow Lockout/Tagout (LOTO) procedures for maintenance. |

| Common Pitfalls | Avoid complacency, ensure thorough training, never bypass safety interlocks, and maintain emergency preparedness. |

Upgrade Your Lab's Safety and Efficiency with KINTEK

Heat treatment is a core process in many laboratories, and ensuring it is performed safely and effectively is paramount. KINTEK specializes in providing reliable lab equipment and consumables designed with safety and performance in mind. Whether you are setting up a new facility or upgrading your current heat treatment operations, our expertise can help you:

- Source furnaces with advanced safety features like atmospheric monitoring and robust safety interlocks.

- Identify the correct material handling tools and PPE to protect your team from extreme temperatures.

- Ensure your lab is equipped for compliance with critical procedures like Lockout/Tagout (LOTO).

Don't let safety risks compromise your results or your team's well-being. Contact KINTEK today to discuss how our solutions can bring peace of mind and superior performance to your laboratory.

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What happens when metal is annealed? A Guide to Softer, More Workable Metals

- What is the function of a high-temperature test furnace in RAFM steel testing? Replicate Nuclear Reactor Conditions

- What does the heating rate during heat treatment depend on? Avoid Cracking and Distortion

- What is vacuum deposition? Achieve Unmatched Purity and Precision in Thin-Film Coatings

- What is the process of vacuum tempering? Achieve a Perfect Balance of Hardness and Toughness

- Why is a laboratory vacuum drying oven essential for N/TiO2-x mesocrystal nanocubes? Protect Your Nanoporous Structure

- How does an electric heating furnace influence the kinetics of waste tire hydrothermal liquefaction? Precision Control

- Why is a vacuum drying oven required for composite cathodes? Ensure Stability in Solution Infiltration Processes