In short, Physical Vapor Deposition (PVD) is a highly versatile coating technology used across a vast range of industries, including aerospace, automotive, medical, cutting tools, consumer goods, and electronics. Its primary applications involve depositing thin, high-performance films to enhance a product's durability, reduce friction, provide chemical or environmental resistance, or create a premium decorative finish.

PVD is not a single solution, but a family of vacuum deposition techniques used to solve specific engineering problems. The core value lies in its ability to grant a base material new surface properties—like extreme hardness, chemical inertness, or low friction—that it does not possess on its own.

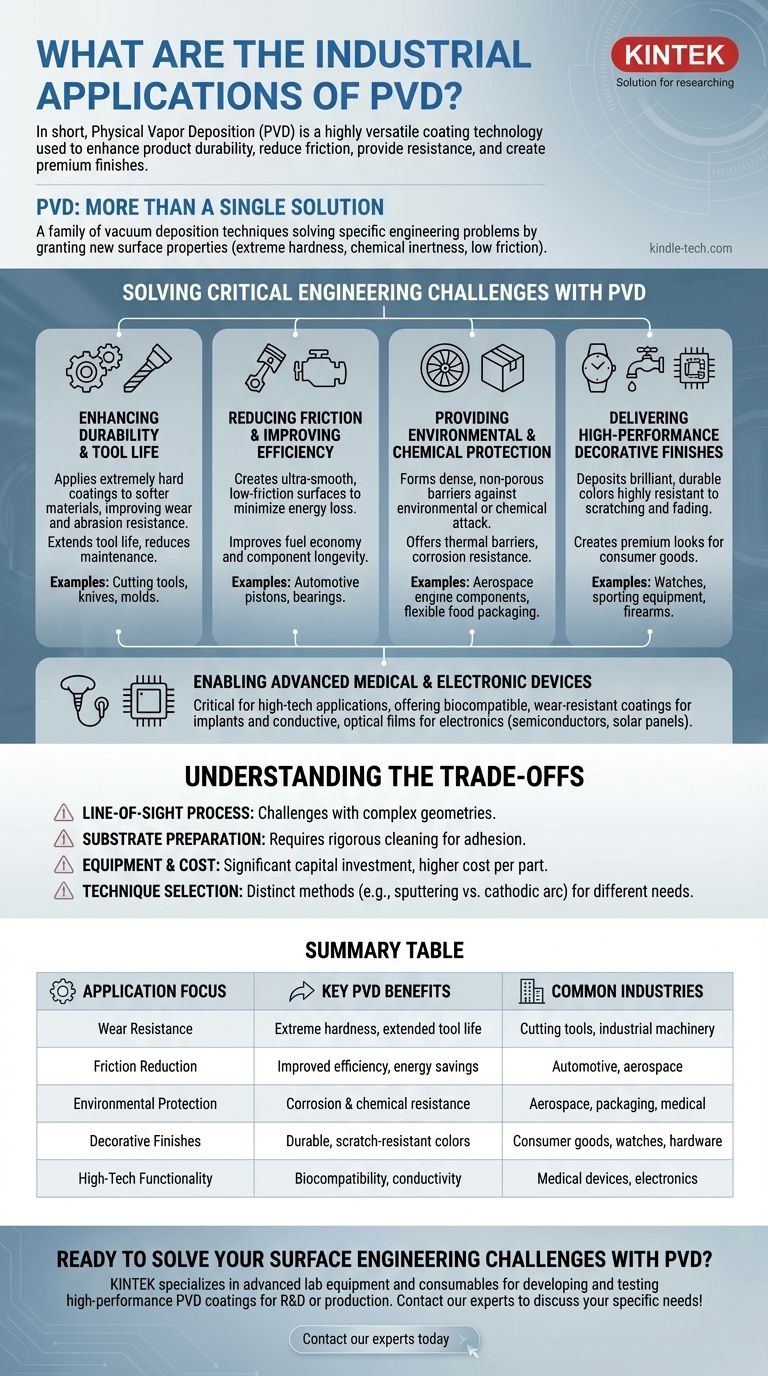

Solving Critical Engineering Challenges with PVD

The adoption of PVD is driven by its ability to address specific functional requirements. Rather than thinking of it by industry, it is more useful to think of it by the problem it solves.

Enhancing Durability and Tool Life

One of the most common uses for PVD is applying extremely hard coatings to softer materials. This dramatically improves resistance to wear and abrasion.

These hard coatings, often nitrides or carbides, are applied to metal cutting tools, knives, and molds. The result is a significant extension of tool life, reduced maintenance, and higher productivity.

Reducing Friction and Improving Efficiency

In high-performance environments, friction is a primary cause of energy loss and wear. PVD coatings create ultra-smooth, low-friction surfaces.

The automotive industry, particularly in motor sports and engine design, uses these coatings on components like pistons and bearings. This reduces frictional energy loss, which directly contributes to improved fuel economy and component longevity.

Providing Environmental and Chemical Protection

PVD films are exceptionally dense and non-porous, making them excellent barriers against environmental or chemical attack.

In aerospace, coatings provide thermal barriers, allowing engine components to withstand extreme temperatures. In flexible packaging, thin metalized films act as a barrier to oxygen, moisture, and light, preserving food. For tools used in harsh settings, PVD provides superior corrosion resistance.

Delivering High-Performance Decorative Finishes

PVD allows for the deposition of thin layers of metal or ceramic that produce a wide range of brilliant, durable colors. These finishes are far more resistant to scratching and fading than paint or traditional plating.

This is widely used on consumer goods like watches, faucets, sporting equipment, and firearms to create a premium look and feel that withstands daily use.

Enabling Advanced Medical and Electronic Devices

The precision and purity of PVD processes are critical for high-tech applications. PVD is used to create biocompatible and wear-resistant coatings for medical implants and surgical tools.

In the electronics sector, it is essential for depositing the thin, conductive, and optical films required for semiconductors, solar panels, and displays.

Understanding the Trade-offs

While PVD offers significant advantages, it is a specialized process with important considerations. Understanding these trade-offs is key to its successful implementation.

Process Limitations

PVD is a line-of-sight process. This means that surfaces to be coated must be directly exposed to the vapor source, which can make it challenging to achieve uniform coverage on parts with complex internal geometries.

Substrate and Preparation

The success of a PVD coating is highly dependent on the cleanliness and preparation of the substrate. Any surface contamination will compromise adhesion, requiring rigorous, multi-step cleaning protocols that add to process time and cost.

Equipment and Cost

PVD is a vacuum-based process, requiring significant capital investment in specialized chambers and equipment. This generally makes it more expensive per part than older, lower-performance technologies like wet painting or some forms of electroplating.

Technique Selection

Different PVD methods (e.g., sputtering, cathodic arc, e-beam evaporation) have distinct characteristics. For example, cathodic arc deposition is very fast and creates tough films but can produce micro-droplets, while sputtering is slower but offers excellent uniformity for precision optics. The right technique must be matched to the application.

Making the Right Choice for Your Application

Selecting the right surface treatment depends entirely on your primary goal. PVD is an exceptional tool when its specific benefits align with your project's critical needs.

- If your primary focus is extreme hardness and wear resistance: Use PVD to apply ceramic coatings like Titanium Nitride (TiN) or Diamond-Like Carbon (DLC) for tools and high-wear components.

- If your primary focus is a durable, premium aesthetic: PVD provides a robust and wide-ranging color palette for consumer products that far outlasts traditional finishes.

- If your primary focus is environmental protection: PVD is an excellent choice for creating dense, impermeable barrier layers for everything from food packaging to aerospace parts.

- If your primary focus is low friction and efficiency: PVD low-friction coatings are a proven solution for reducing energy loss in high-performance mechanical systems.

Ultimately, PVD is a key enabling technology that allows engineers and designers to create products that are stronger, more efficient, and more durable.

Summary Table:

| Application Focus | Key PVD Benefits | Common Industries |

|---|---|---|

| Wear Resistance | Extreme hardness, extended tool life | Cutting tools, industrial machinery |

| Friction Reduction | Improved efficiency, energy savings | Automotive, aerospace |

| Environmental Protection | Corrosion & chemical resistance | Aerospace, packaging, medical |

| Decorative Finishes | Durable, scratch-resistant colors | Consumer goods, watches, hardware |

| High-Tech Functionality | Biocompatibility, conductivity | Medical devices, electronics |

Ready to solve your surface engineering challenges with PVD? KINTEK specializes in advanced lab equipment and consumables for developing and testing high-performance PVD coatings. Whether you're in R&D or production, our solutions help you achieve superior durability, efficiency, and finish quality. Contact our experts today to discuss how we can support your laboratory's specific needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition