The primary advantages of freeze drying are its unparalleled ability to preserve a material's original quality, structure, and nutritional value. By removing moisture at low temperatures under a vacuum, it avoids the damage caused by heat-based dehydration, resulting in a lightweight product with an exceptionally long shelf life that can be easily rehydrated to a near-original state.

Freeze drying's core value is not merely in removing water, but in preserving the fundamental integrity of the material itself. It excels where the preservation of structure, biological activity, and sensory characteristics is non-negotiable.

Why Freeze Drying Preserves Quality So Well

Traditional drying uses heat to evaporate water, which cooks the product and fundamentally alters its chemical and physical structure. Freeze drying, or lyophilization, works on a completely different principle.

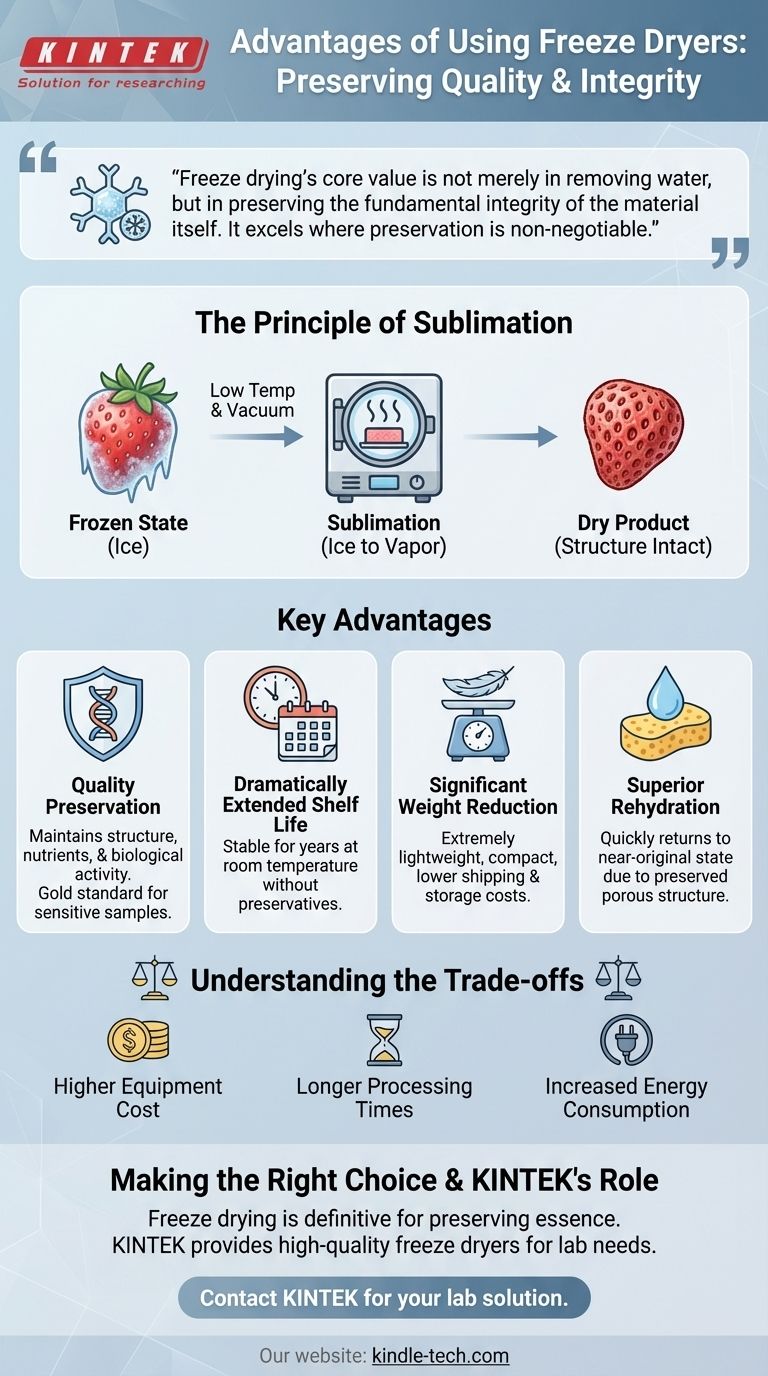

The Principle of Sublimation

Freeze drying is a low-temperature dehydration process. It involves freezing the material and then reducing the surrounding pressure to allow the frozen water to transition directly from a solid state (ice) to a gaseous state (water vapor) without passing through the liquid phase.

This process, called sublimation, is the key to its gentle nature. Because the water is never in a liquid state that can damage cell walls or dissolve sensitive compounds, the product's structure is left intact.

Retaining Nutritional and Biological Integrity

Heat can destroy vitamins, denature proteins, and degrade sensitive biological compounds. The low-temperature environment of a freeze dryer minimizes these impacts.

This makes it the gold standard for preserving heat-sensitive materials like pharmaceuticals, vaccines, and biological samples. In food, it ensures that vitamins, flavors, and aromas are retained to a degree that other methods cannot match.

Maintaining Physical Structure

When you use heat to dry something, water leaves the structure, causing it to shrink, toughen, and become dense.

Freeze drying leaves the product's microscopic structure largely undamaged. This porous, sponge-like framework is why freeze-dried materials rehydrate so quickly and completely, returning to a quality considered nearly identical to fresh.

The Practical and Logistical Advantages

The superior preservation method translates into significant real-world benefits for storage, transport, and use.

Dramatically Extended Shelf Life

By removing virtually all water content, freeze drying halts the microbial growth and enzymatic reactions that cause spoilage.

This allows products to be stored for years at room temperature without refrigeration or chemical preservatives, making it ideal for archival purposes and emergency food supplies.

Significant Weight Reduction

Water is heavy. Removing it makes the final product extremely lightweight and compact.

This drastically reduces shipping costs and makes products easier to handle and store. It's why freeze drying is favored for backpacking meals, military rations, and shipping expensive biologicals.

Superior Rehydration

Because the physical structure is preserved, water can easily re-enter the material's pores.

This allows freeze-dried foods, instant coffee, and pharmaceutical compounds to be reconstituted almost instantly by simply adding water, with texture and taste far superior to traditionally dried products.

Understanding the Trade-offs

While its benefits are significant, freeze drying is not the universal solution for all dehydration needs. Objectivity requires acknowledging its limitations.

Higher Equipment Cost

Freeze dryers are complex machines involving refrigeration systems, vacuum pumps, and sophisticated controls. This makes the initial capital investment significantly higher than that of a simple dehydrator or oven.

Longer Processing Times

The entire process—pre-freezing, primary drying (sublimation), and secondary drying—is methodical and can take many hours or even days, depending on the material. This is much slower than heat-based methods.

Increased Energy Consumption

Operating refrigeration units and vacuum pumps for extended periods consumes a considerable amount of energy, leading to higher operational costs compared to simpler drying techniques.

Making the Right Choice for Your Goal

Selecting the right preservation method depends entirely on your priorities and the nature of the material you are working with.

- If your primary focus is preserving maximum quality and biological activity: For pharmaceuticals, research samples, or high-end foods, freeze drying is the superior and often the only viable choice.

- If your primary focus is simple, cost-effective water removal: For applications where some degradation in texture and nutritional value is acceptable, traditional heat dehydration may be more practical.

- If your primary focus is creating lightweight, shelf-stable products for long-term storage: Freeze drying offers the best combination of weight reduction, extended shelf life, and quality upon rehydration.

Ultimately, freeze drying is the definitive technology for when you need to remove water without destroying the essence of the original material.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Quality Preservation | Maintains structure, nutrients, and biological activity. |

| Extended Shelf Life | Stable for years without refrigeration. |

| Lightweight & Compact | Reduces shipping and storage costs. |

| Superior Rehydration | Quickly returns to near-original state. |

Ready to preserve your materials with laboratory precision?

Freeze drying is the definitive technology for removing water without destroying the essence of your original material. KINTEK specializes in providing high-quality lab equipment, including freeze dryers, to meet the demanding needs of laboratories in pharmaceuticals, food science, and biotechnology.

Our expertise ensures you get the right equipment to achieve superior preservation, extended shelf life, and significant logistical advantages for your sensitive samples and products.

Contact KINTEK today to find the perfect freeze-drying solution for your lab!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What role does a laboratory freeze dryer play in the synthesis of graphene-based electrocatalysts? Preserve 3D Structures

- Why is a laboratory vacuum freeze dryer essential for plant extracts? Preserve Bioactivity & Structure

- Why is a laboratory freeze-drying system essential for fermentation biomass? Preserve Sample Integrity for Analysis

- What is the purpose of an evaporator? The Key Component That Creates Cooling

- Why is a freeze dryer preferred for drying nickel nanoparticle precursors? Prevent Hard Agglomeration Now