While a foundational and widely used technique, sieve analysis is far from a universally perfect solution for particle size determination. Its primary limitations stem from its reliance on particle shape, its ineffectiveness with very fine or cohesive powders, and its susceptibility to physical and procedural errors. Sieving assumes particles are perfect spheres, a condition rarely met in reality, which can lead to significant misinterpretations of the true size distribution.

Sieve analysis does not measure a particle's true size; it measures whether a particle can pass through a specific aperture. Its accuracy is therefore fundamentally dependent on the material's shape and flow characteristics, making it an excellent tool for some materials and a misleading one for others.

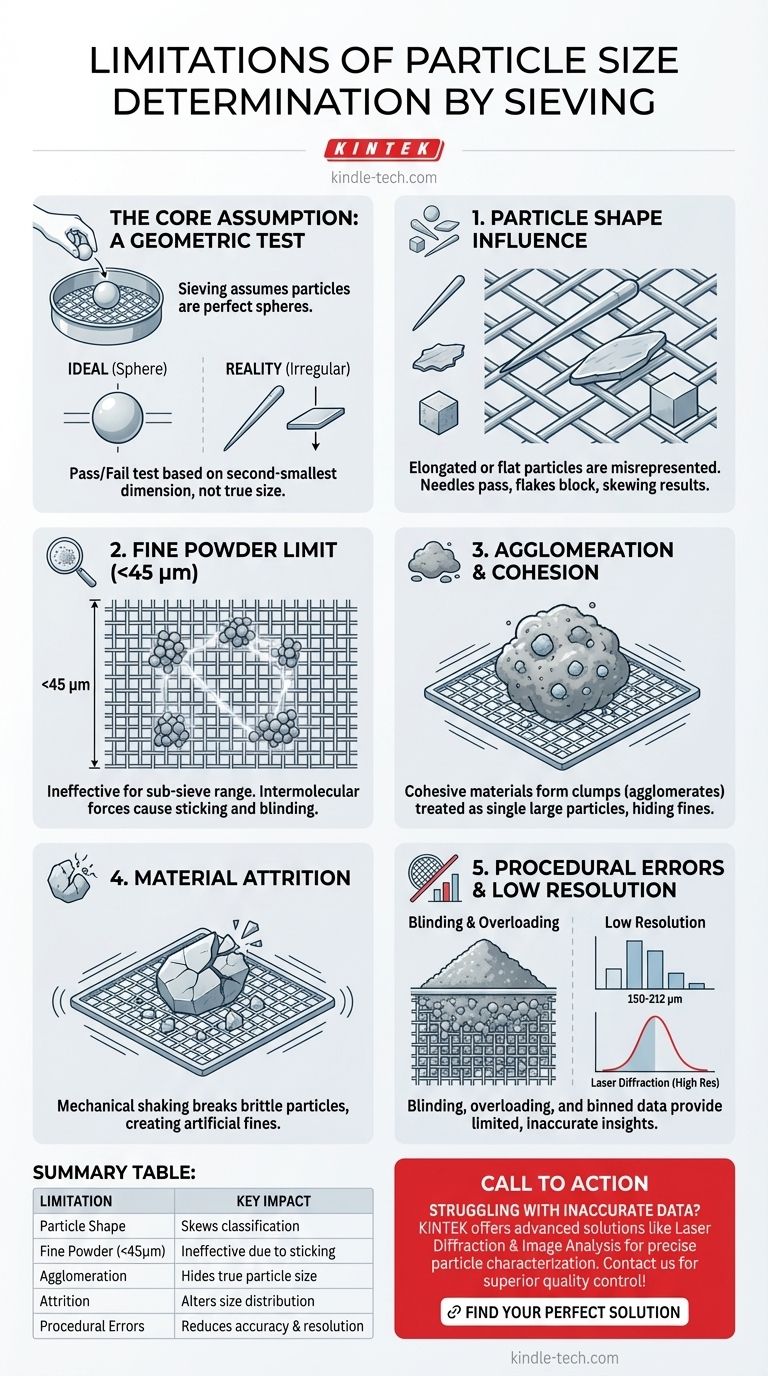

The Core Assumption of Sieving: A Geometric Test

To understand the limitations, you must first understand the principle. Sieving is not a direct measurement but a pass/fail test repeated over a series of decreasing aperture sizes.

How Sieving Works: A Mechanical Filter

Sieve analysis involves shaking a pre-weighed sample of material through a stack of woven-wire or perforated-plate screens, each with a precisely defined hole size. Particles larger than the openings are retained, while smaller particles pass through to the sieve below, effectively sorting the material into size fractions.

The "Sieve Diameter" vs. True Particle Size

The result of a sieve analysis is a "sieve diameter." This is the dimension of the mesh aperture that the particle just passes through. For a spherical particle, this is its actual diameter. However, for an irregularly shaped particle, it represents the particle's second-smallest dimension.

A long, needle-shaped particle, for instance, can pass end-on through a hole that is much smaller than its total length, leading to it being classified in a much finer fraction than its volume or mass would suggest.

Fundamental Limitations of Sieve Analysis

These limitations arise directly from the mechanical nature of the test and the physical properties of the material being analyzed.

The Influence of Particle Shape

This is the most significant limitation. Elongated (acicular) or flat (platy) particles skew results. A flaky material might block the sieve apertures, while a needle-like material will pass through easily, making both appear smaller than they are in a volumetric sense.

The Lower Limit: When Particles Become Too Fine

Sieve analysis is generally unreliable for particles smaller than approximately 38-45 micrometers (µm). Below this "sub-sieve" range, intermolecular forces like van der Waals forces and electrostatic charges become stronger than gravitational forces.

This causes fine particles to stick to each other and to the sieve mesh itself, preventing them from passing through apertures they would otherwise fit through.

The Problem of Agglomeration and Cohesion

Even above the sub-sieve range, materials that are moist, oily, or naturally cohesive will form clumps or agglomerates. The sieve shaker treats each agglomerate as a single large particle. This gives a falsely coarse result, hiding the true size of the primary particles within the clump.

Material Attrition: Breaking Particles During Analysis

The mechanical shaking action required for sieving can cause attrition—the breaking down of brittle or friable particles. This process creates new, smaller particles (fines) that were not present in the original sample, skewing the distribution toward the finer end.

Understanding the Trade-offs and Practical Errors

Beyond its inherent physical limitations, sieve analysis is prone to errors that can compromise the quality of the data.

Sieve Blinding and Overloading

Sieve blinding occurs when particles become trapped in the mesh openings, effectively reducing the open area of the sieve. This prevents other, smaller particles from passing through. Overloading a sieve with too much sample has a similar effect, creating a bed of material that is too deep to be sorted effectively in a reasonable time.

Sampling and Procedural Variability

The result is only as good as the sample provided. Obtaining a truly representative sample from a large batch is a major challenge. Furthermore, factors like shaking time, amplitude, and tapping motion can vary between operators and instruments, introducing significant variability into the results.

The Misconception of High Resolution

Sieve analysis provides a low-resolution histogram of the particle size distribution. You only know that a particle's size falls between the two sieve sizes it was separated by (e.g., between 150 µm and 212 µm). You get no information about the distribution within that range, unlike continuous measurement techniques like laser diffraction.

Making the Right Choice for Your Goal

Use this framework to determine if sieving is appropriate for your application.

- If your primary focus is quality control for coarse, free-flowing materials (>100 µm): Sieving is often the ideal, cost-effective choice for materials like sand, gravel, grains, and plastic pellets.

- If your primary focus is characterizing fine powders or nanoparticles (<45 µm): Sieving is not a viable method; you must use an alternative like laser diffraction or dynamic light scattering (DLS).

- If your primary focus is analyzing irregularly shaped particles (fibers, flakes): Sieve results will be biased and potentially misleading. Optical techniques like automated image analysis are far superior.

- If your primary focus is achieving a high-resolution distribution for research or process optimization: Sieving's binned, low-resolution output is a major drawback. Consider laser diffraction to get a detailed, continuous distribution curve.

Ultimately, selecting the right particle analysis technique requires a clear understanding of both your material's properties and the specific question you need to answer.

Summary Table:

| Limitation | Key Impact | Common Issues |

|---|---|---|

| Particle Shape | Skews size classification | Elongated/flat particles misreported |

| Fine Powder Limit (<45µm) | Ineffective for cohesive materials | Particle agglomeration and blinding |

| Mechanical Attrition | Alters original particle distribution | Brittle materials break during shaking |

| Sieve Blinding/Overloading | Reduces sorting efficiency | Blocked apertures and inaccurate results |

Struggling with inaccurate particle size data? Sieve analysis limitations can hinder your lab's efficiency and research accuracy. KINTEK specializes in advanced lab equipment and consumables, offering precise alternatives like laser diffraction and image analysis systems tailored to your specific material properties. Our expertise ensures you get reliable, high-resolution particle size distributions for superior quality control and research outcomes. Contact us today to find the perfect solution for your laboratory needs!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- What are the apparatus used for sieve analysis? Build a Reliable Particle Sizing System

- What are the advantages of the sieve method? Achieve Fast, Reliable Particle Size Analysis

- What type of materials can be separated using the method of sieving? A Guide to Efficient Particle Size Separation

- How do you use a sieve shaker? Master Particle Size Analysis for Quality Control

- What range of particle size does the sieve analysis apply? Master the 25 Micron to 1 mm Standard