The primary advantage of freeze drying is its unparalleled ability to preserve a material's original quality. By removing water at low temperatures under a vacuum, this process—also known as lyophilization—maintains the product's physical structure, nutritional value, biological activity, and sensory characteristics like flavor and aroma. The result is a highly stable, lightweight product that is considered nearly identical to its fresh counterpart upon rehydration.

Traditional drying methods use heat, which can irreversibly damage the structure and chemical composition of sensitive materials. Freeze drying avoids this by turning ice directly into vapor, a gentle process called sublimation that locks in the original quality of the product.

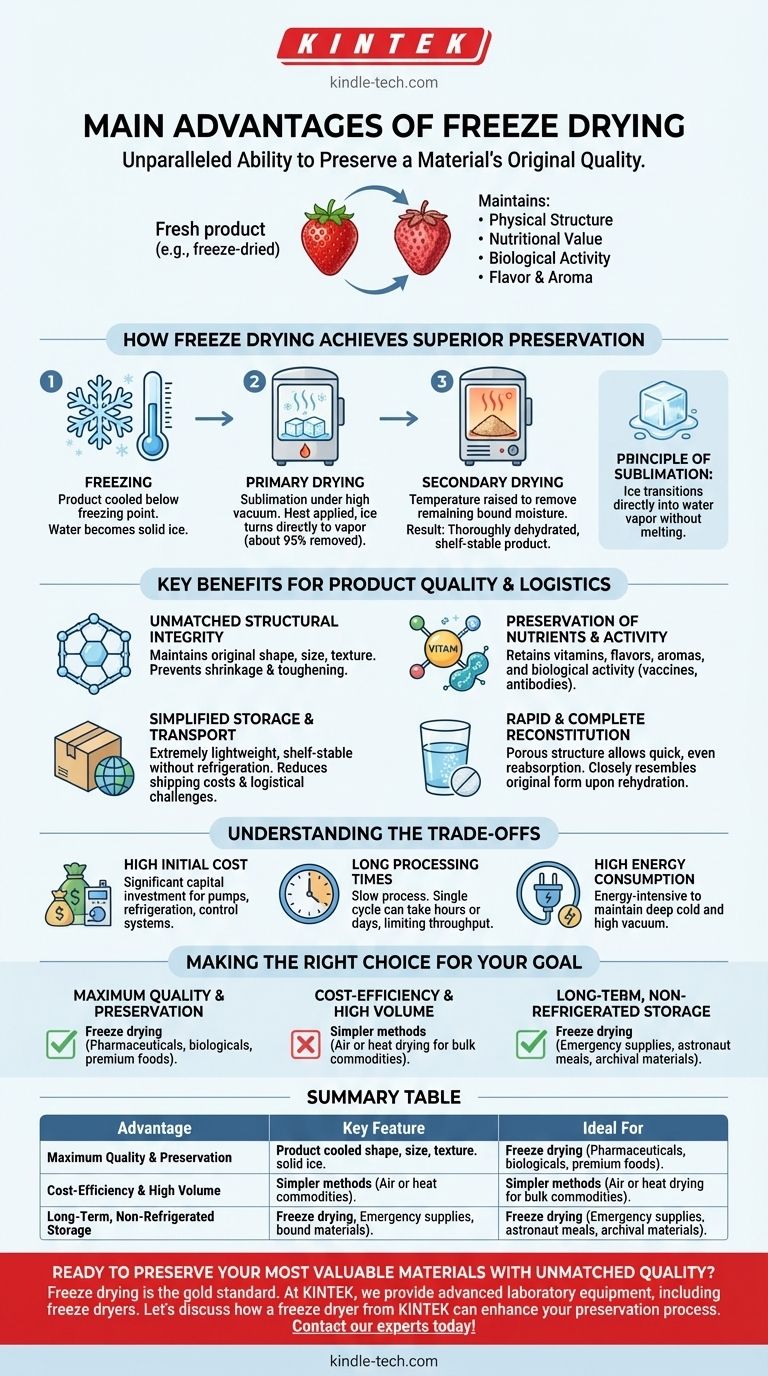

How Freeze Drying Achieves Superior Preservation

Freeze drying is a sophisticated, multi-stage process fundamentally designed to avoid the damage caused by heat and water in its liquid state.

The Principle of Sublimation

The core of the process is sublimation. After a product is frozen solid, it's placed under a deep vacuum. This allows the frozen water (ice) to transition directly into water vapor without ever melting into a liquid, gently removing moisture while leaving the product's structure intact.

A Low-Temperature Process

The entire primary drying phase occurs at low temperatures. This is critical for preserving heat-sensitive materials, such as the active ingredients in vaccines, the delicate structures of proteins, and the nutritional value of vitamins in food.

The Three-Stage Process

The method is highly controlled and consists of three key stages:

- Freezing: The product is cooled well below its freezing point to ensure all water becomes solid ice.

- Primary Drying: Under a high vacuum, heat is gently applied, causing about 95% of the ice to sublimate into vapor, which is then collected on a cold condenser.

- Secondary Drying: The temperature is gradually raised to remove the remaining bound moisture, resulting in a thoroughly dehydrated, shelf-stable product.

Key Benefits for Product Quality and Logistics

The unique mechanism of freeze drying translates into several significant practical advantages for a wide range of applications, from pharmaceuticals to high-quality food.

Unmatched Structural Integrity

Because the water is removed from a solid state, the product's cellular structure is not compromised. This means the original shape, size, and texture are maintained, preventing the shrinkage and toughening common with heat-based dehydration.

Preservation of Nutrients and Activity

By avoiding high temperatures, freeze drying excels at preserving the biological activity of sensitive products like vaccines and antibodies. For food, it retains vitamins, flavors, and aromas that are typically lost during conventional drying.

Simplified Storage and Transport

Once freeze-dried, products are extremely lightweight and shelf-stable without refrigeration or chemical preservatives. This drastically reduces shipping costs and simplifies logistical challenges for everything from military rations to pharmaceutical distribution.

Rapid and Complete Reconstitution

The porous structure left behind by the sublimated ice crystals allows water to be reabsorbed quickly and evenly. This enables freeze-dried materials, from instant coffee to biological reagents, to be returned to a state closely resembling their original form.

Understanding the Trade-offs

While its benefits are significant, freeze drying is not the optimal solution for every scenario. Acknowledging its limitations is key to making an informed decision.

High Initial Cost

The equipment required for freeze drying—specifically the vacuum pumps, refrigeration units, and control systems—represents a significant capital investment compared to simpler dehydration technologies.

Long Processing Times

The process is inherently slow. A single cycle of freezing, primary drying, and secondary drying can take many hours or even several days to complete, which can limit production throughput.

High Energy Consumption

Maintaining deep cold and a high vacuum is an energy-intensive process. The operational costs associated with electricity can be substantially higher than those for conventional hot-air drying methods.

Making the Right Choice for Your Goal

The decision to use freeze drying depends entirely on whether its superior preservation quality justifies the investment in time and cost for your specific application.

- If your primary focus is maximum quality and preservation: Freeze drying is the superior choice for high-value, sensitive materials like pharmaceuticals, biologicals, or premium foods where integrity is non-negotiable.

- If your primary focus is cost-efficiency and high volume: Simpler methods like air or heat drying may be more practical for bulk commodities where some degradation in quality is an acceptable trade-off for lower costs.

- If your primary focus is long-term, non-refrigerated storage: Freeze drying offers exceptional shelf stability and light weight, making it ideal for emergency supplies, astronaut meals, and archival materials.

Ultimately, freeze drying is an investment in preserving the inherent value and integrity of the original product.

Summary Table:

| Advantage | Key Feature | Ideal For |

|---|---|---|

| Superior Quality Preservation | Removes water via sublimation at low temperatures | Pharmaceuticals, high-value foods, biological samples |

| Maintains Structural Integrity | Prevents shrinkage and damage; product retains original shape | Instant coffee, fruits, vaccines, proteins |

| Long-Term Shelf Stability | Lightweight, stable at room temperature; no refrigeration needed | Emergency supplies, military rations, archival materials |

| Rapid & Complete Reconstitution | Porous structure allows quick and even rehydration | Instant meals, laboratory reagents, specialty ingredients |

Ready to Preserve Your Most Valuable Materials with Unmatched Quality?

Freeze drying is the gold standard for protecting the integrity, potency, and shelf life of sensitive products. At KINTEK, we specialize in providing advanced laboratory equipment, including freeze dryers, to meet the precise needs of research, pharmaceutical, and food science laboratories.

Our solutions help you:

- Maintain Critical Product Quality: Preserve the biological activity, nutrients, and structure of your most delicate materials.

- Simplify Logistics: Create lightweight, shelf-stable products that reduce storage and shipping costs.

- Scale Your Operations: From R&D to production, find the right equipment for your specific application.

Let's discuss how a freeze dryer from KINTEK can enhance your preservation process. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why is a laboratory freeze-drying system essential for fermentation biomass? Preserve Sample Integrity for Analysis

- What are the advantages of using freeze drying for phase change materials with biopolymer shells? Optimize Stability

- What is the function of Freeze-thaw Equipment in Au-(PNiPAAm/PVA) hydrogel? Achieve High-Speed Photothermal Actuation

- What role does a laboratory freeze dryer play in the synthesis of graphene-based electrocatalysts? Preserve 3D Structures

- Why is a freeze dryer preferred for drying nickel nanoparticle precursors? Prevent Hard Agglomeration Now