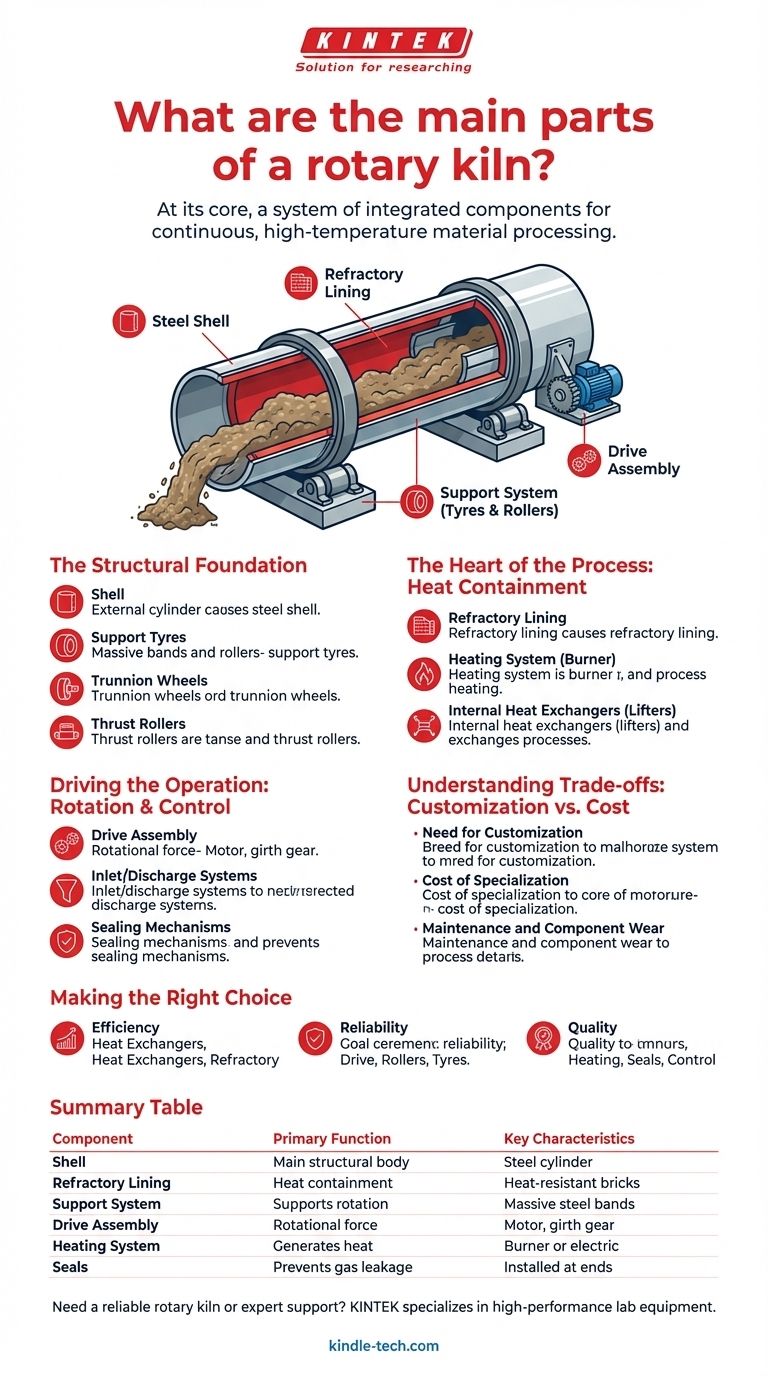

At its core, a rotary kiln is a system of integrated components designed for continuous, high-temperature material processing. The main parts are the steel shell, the protective internal refractory lining, the support system (tyres and rollers) that allows it to rotate, and the drive assembly that provides the rotational force. These components work in unison to move material through a controlled heating environment.

A rotary kiln is not merely a heated tube; it is a dynamic system. Understanding how each component contributes to structural integrity, heat containment, and material transport is essential to grasping its function and operational demands.

The Structural Foundation: Shell and Support

The immense size and weight of a rotary kiln necessitate a robust structural and support system. These components bear the mechanical loads of rotation and the thermal stresses of the process.

The Kiln Shell

The shell is the external steel cylinder that forms the main body of the kiln. It is often slightly inclined to allow gravity to assist in moving material from the feed end to the discharge end. This shell must withstand significant torsion and bending stresses as it rotates.

Support Tyres (Riding Rings)

Support tyres, also known as riding rings, are massive steel bands attached to the outside of the kiln shell. These tyres provide a smooth, strong surface for the kiln to ride on as it rotates.

Trunnion Wheels and Support Rollers

The kiln's entire weight is transferred from the tyres to a series of trunnion wheels or support rollers. These heavy-duty wheels are mounted on bearings and provide the low-friction surface that enables the massive shell to turn.

Thrust Rollers

To counteract the kiln's natural tendency to slide downhill due to its inclination, thrust rollers are positioned to push against the side of a support tyre. This keeps the entire kiln assembly in its correct longitudinal position.

The Heart of the Process: Heat Containment and Transfer

The primary purpose of the kiln is to heat material. The following components manage the extreme temperatures required for thermal processing.

Refractory Lining

The refractory lining is arguably the most critical internal component. It is a layer of heat-resistant bricks or castable material that protects the steel shell from the extreme internal temperatures, which can exceed 1450°C (2640°F). It also prevents chemical reactions between the hot material and the steel shell.

The Heating System

Heat is typically generated by a large burner mounted at the discharge end of the kiln, creating a counter-current flow of hot gas against the material. In some specialized applications, electric heating elements may be used to provide precise, uniform heat.

Internal Heat Exchangers

To improve efficiency, many kilns feature internal structures like lifters or flights. These metal plates lift material and cascade it through the hot gas stream, ensuring more uniform heat exposure and accelerating the process.

Driving the Operation: Rotation and Control

The kiln's dynamic nature is managed by the drive system and components that control the flow of material.

The Drive Assembly

The drive assembly is the powerhouse that rotates the kiln. It consists of a motor connected to a large gear (a girth gear) that encircles the shell. Common drive types include gear, chain and sprocket, or friction drives, each providing the immense torque needed to turn the kiln.

Inlet and Discharge Systems

Material enters the kiln through a feeding device at the upper end and exits through discharge breeching at the lower end. These systems are designed to ensure a steady, controlled flow of material through the kiln.

Sealing Mechanisms

Effective seals are installed at both the feed and discharge ends of the kiln. Their job is to prevent cold air from entering the system, stop valuable hot gas from escaping, and contain dust and raw material.

Understanding the Trade-offs: Customization vs. Cost

While the core components are universal, their specific design is a balance between performance requirements and economic reality.

The Need for Customization

The material being processed dictates the kiln's design. Factors like corrosiveness, required temperature profile, and particle size influence the choice of refractory material, the design of internal lifters, and the type of sealing system used.

The Cost of Specialization

This high degree of customization means that rotary kilns are expensive capital equipment. Specialized alloys, high-performance refractory, and complex control systems all add to the initial investment cost.

Maintenance and Component Wear

Rotary kilns are harsh operating environments. The refractory lining, seals, tyres, and rollers are all considered wear parts that require regular inspection and eventual replacement, representing a significant ongoing operational cost.

Making the Right Choice for Your Goal

Understanding how these parts interrelate helps you focus on what matters most for your specific operational objective.

- If your primary focus is process efficiency: The design of the internal heat exchangers and the thermal properties of the refractory lining are your most critical components.

- If your primary focus is mechanical reliability: The integrity of the drive assembly, the alignment of the support rollers, and the condition of the tyres are paramount.

- If your primary focus is product quality: The precision of the heating system, the effectiveness of the seals, and the overall control unit are essential for maintaining a stable processing environment.

By viewing the rotary kiln as an integrated system, you can better diagnose problems, optimize performance, and appreciate the engineering behind this powerful industrial tool.

Summary Table:

| Component | Primary Function | Key Characteristics |

|---|---|---|

| Shell | Main structural body | Steel cylinder, inclined for material flow |

| Refractory Lining | Heat containment and protection | Heat-resistant bricks or castable material |

| Support System (Tyres & Rollers) | Supports and enables rotation | Massive steel bands, trunnion wheels, thrust rollers |

| Drive Assembly | Provides rotational force | Motor, girth gear, high-torque drive system |

| Heating System | Generates process heat | Burner or electric elements, counter-current flow |

| Seals | Prevents gas leakage and air ingress | Installed at feed and discharge ends |

Need a reliable rotary kiln or expert support for your lab? KINTEK specializes in high-performance lab equipment, including rotary kilns tailored for precise thermal processing. Our solutions ensure efficiency, durability, and optimal results for your laboratory needs. Contact us today to discuss how we can support your projects with the right equipment and expertise!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- What is the purpose of a calciner? Boost Efficiency in High-Temperature Processing

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products

- What are the types of pyrolysis reactors used in industry? Choose the Right Technology for Your Product