Operating an acrylic electrolytic cell requires a methodical approach that balances procedural precision with rigorous safety. The process involves careful preparation of the cell and electrolyte, controlled execution of the experiment while monitoring key parameters, and the consistent use of personal protective equipment to mitigate chemical, electrical, and gas-related hazards.

Successful and safe electrolysis hinges on a single principle: controlled observation. This means not just following steps, but understanding why you are taking them—from preventing contamination before the experiment to actively managing risks like gas buildup and electrical exposure during it.

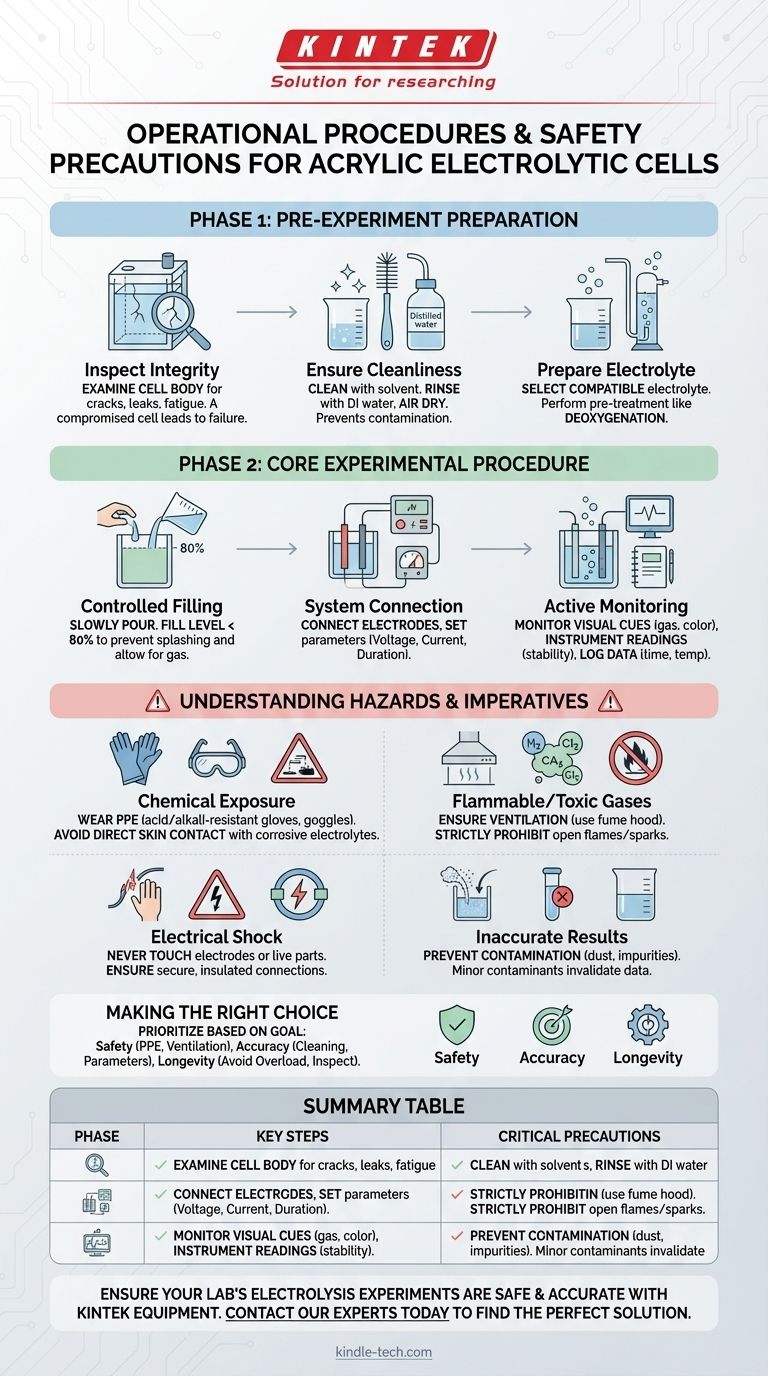

Phase 1: Pre-Experiment Preparation

Before any power is applied, the foundation for a safe and accurate experiment is laid. Diligent preparation prevents equipment failure and ensures the validity of your results.

Inspect for Physical Integrity

Before each use, carefully examine the acrylic cell body. Look for any cracks, leaks, or signs of material fatigue. A compromised cell can lead to dangerous leaks and catastrophic failure during operation.

Ensure Absolute Cleanliness

The cell must be free of contaminants. First, clean it with a suitable solvent to remove any grease or organic residues. Follow this by rinsing thoroughly with distilled or deionized water and allowing it to air dry completely. This prevents unintended side reactions.

Prepare the Electrolyte

Select an electrolyte that is compatible with the acrylic cell and your electrode materials. Prepare the solution according to your experimental protocol, which may include pre-treatment steps like deoxygenation to remove dissolved oxygen that could interfere with your reaction.

Phase 2: Core Experimental Procedure

Once the system is prepared, the operational phase demands precision and constant awareness. Every action, from filling the cell to setting parameters, is a critical control point.

Controlled Filling Technique

Slowly pour the prepared electrolyte into the cell. The fill level should not exceed 80% of the cell's total volume. This practice prevents splashing during handling and provides headspace for any gases that evolve during electrolysis.

System Connection and Parameterization

Correctly connect the cell's electrodes to the power supply and any monitoring instruments. Before starting, set the required experimental parameters, such as voltage, current, and duration, according to your specific objectives.

Active Monitoring and Data Logging

Once the experiment begins, active observation is critical.

- Visual Cues: Watch for normal gas bubble formation on the electrode surfaces and note any unexpected color changes in the electrolyte.

- Instrument Readings: Monitor for a stable current and voltage. Fluctuations can indicate problems with the connections or the reaction itself.

- Data Recording: Systematically log key data points, including electrolysis time, temperature, and the visual status of the electrolyte. This data is essential for analysis and reproducibility.

Understanding the Hazards and Imperatives

An electrolytic cell is an active electrochemical system with inherent risks. Understanding these hazards is not optional; it is a prerequisite for safe operation.

The Hazard of Chemical Exposure

The electrolytes used are often corrosive or toxic. Always wear acid and alkali-resistant gloves and safety goggles. Avoid any direct skin contact with the electrolyte to prevent chemical burns.

The Risk of Flammable and Toxic Gases

Electrolysis can produce hazardous gases. For example, the electrolysis of brine can release chlorine gas, while splitting water produces a potentially explosive mixture of hydrogen and oxygen.

- Ensure the workspace is well-ventilated at all times. Using a fume hood is the best practice.

- Strictly prohibit open flames, sparks, or other ignition sources in the vicinity of the cell to prevent fire or explosion.

The Danger of Electrical Shock

The system operates with a live electrical current. Never touch the electrodes or other conductive parts of the circuit while the power supply is on. Ensure all connections are secure and insulated.

The Threat of Inaccurate Results

Contamination is the enemy of good data. During operation, take care to prevent dust, impurities, or other foreign materials from entering the cell. Even minor contaminants can alter the electrochemical process and invalidate your results.

Making the Right Choice for Your Goal

Your primary goal dictates where your focus should lie. Use this framework to prioritize your actions for a successful and safe experiment.

- If your primary focus is safety: Your non-negotiable first step is always wearing appropriate PPE (gloves, goggles) and ensuring proper ventilation before any other action.

- If your primary focus is data accuracy: Meticulous cleaning and preventing contamination during the run are just as crucial as setting the correct electrical parameters.

- If your primary focus is equipment longevity: Avoid prolonged overload operation and inspect the cell for damage before every single use to prevent irreversible failure.

By treating each step as a critical control point, you transform a routine procedure into a safe, reliable, and successful experiment.

Summary Table:

| Phase | Key Steps | Critical Precautions |

|---|---|---|

| Preparation | Inspect cell for cracks, clean with solvent/DI water, prepare electrolyte. | Ensure material compatibility, prevent contamination. |

| Operation | Fill to 80% capacity, set electrical parameters, monitor gas formation & stability. | Wear PPE (gloves, goggles), ensure ventilation, no open flames. |

| Hazard Focus | - | Mitigate chemical exposure, flammable/toxic gases, electrical shock. |

Ensure your lab's electrolysis experiments are both safe and accurate with the right equipment. KINTEK specializes in high-quality lab equipment and consumables, including durable acrylic electrolytic cells designed for precise control and user safety. Our products help you mitigate risks and achieve reliable results. Contact our experts today to find the perfect solution for your laboratory's specific needs.

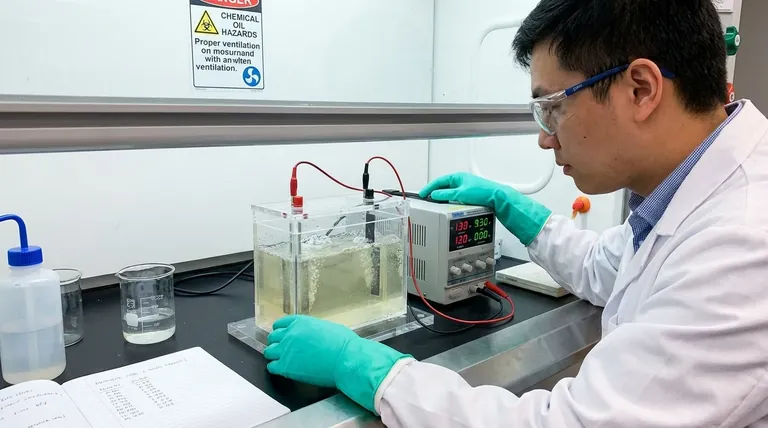

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Benchtop Laboratory Freeze Dryer for Lab Use

- Button Battery Case for Battery Lab Applications

People Also Ask

- What is the primary purpose of using standard sieves? Master Particle Uniformity for High-Quality Catalyst Preparation

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- What are the specifications for test sieves? A Guide to ASTM & ISO Standards for Accurate Particle Analysis

- How is a vibratory sieve shaker used in the particle size analysis of mechanically alloyed powders? Expert Guide

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis