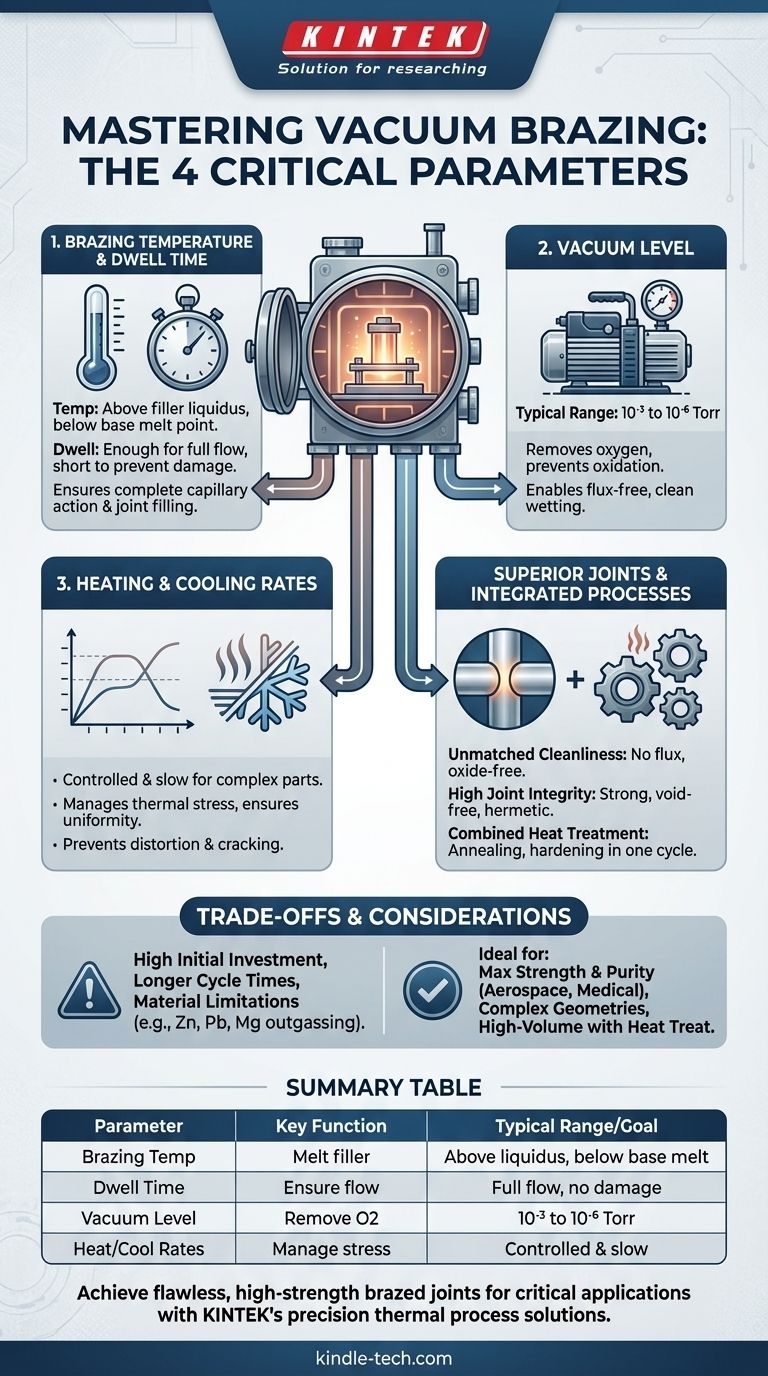

At its core, vacuum brazing is governed by four critical parameters: the brazing temperature, the dwell time at that temperature, the heating and cooling rates, and the vacuum level within the furnace. These parameters work in concert not just to melt a filler metal, but to create a highly controlled atmospheric environment that enables exceptionally clean, strong, and flux-free joints.

The central takeaway is that vacuum brazing is a holistic thermal process. Success depends less on any single setting and more on the precise control of the entire cycle—using the vacuum itself as an active tool to prepare the surfaces and protect the materials.

The Core Parameters of a Vacuum Brazing Cycle

Understanding how each parameter functions is key to mastering the process and achieving its significant benefits. The entire cycle is a carefully choreographed sequence of heating, soaking, and cooling within a controlled environment.

Brazing Temperature and Dwell Time

The brazing temperature is the specific point at which the filler metal becomes molten and flows into the joint via capillary action. This temperature must be above the filler metal's melting point (liquidus) but below the base materials' melting point.

Dwell time is the duration the assembly is held at this peak temperature. This period must be long enough to ensure the filler metal is fully molten and has completely filled the joint, but not so long that it causes unwanted metallurgical reactions or grain growth in the base materials.

Vacuum Level

The vacuum level is arguably what defines this process. It is not simply the absence of air but the active removal of reactive gases like oxygen. A proper vacuum (typically in the range of 10⁻³ to 10⁻⁶ Torr) prevents oxidation of the parts as they heat up.

This clean, oxide-free surface is essential for proper wetting, where the molten filler metal spreads evenly across the base materials. This eliminates the need for chemical fluxes, which can otherwise leave behind corrosive residues.

Controlled Heating and Cooling Rates

The rate at which the assembly is heated and cooled is a critical parameter for managing thermal stress. A slow, controlled heating rate ensures temperature uniformity across the entire part, which is vital for complex geometries or assemblies of dissimilar materials.

Likewise, a controlled cooling rate prevents distortion, cracking, and the introduction of residual stresses. This slow cycle preserves the mechanical properties of the parent materials, ensuring the final assembly is strong and dimensionally stable.

How These Parameters Create Superior Joints

The precise control of these parameters directly leads to the well-known advantages of vacuum brazing. The process is far more than a simple joining method; it is an integrated manufacturing step.

Achieving Unmatched Cleanliness

The high vacuum environment effectively vaporizes surface contaminants like oils and grease while preventing the formation of oxides. This results in bright, clean parts straight from the furnace, with no risk of flux entrapment or post-braze corrosion in the joint.

Ensuring High Joint Integrity

Because the vacuum creates an ideal, ultra-clean surface, the molten filler metal can flow perfectly into the joint. This creates a thin, uniform bond line that is free of voids and impurities, resulting in superior strength and hermetic seals.

Combining Brazing with Heat Treatment

The programmable nature of a vacuum furnace cycle allows for multiple processes to occur in one run. Brazing can be combined with subsequent heat treatments like annealing, hardening, or age hardening by programming specific holds and cooling rates (including rapid gas quenching options in some furnaces). This consolidation dramatically improves efficiency, especially in high-volume production.

Understanding the Trade-offs

While powerful, vacuum brazing is not the universal solution for all joining applications. Its primary limitations are practical and economic.

High Initial Investment

Vacuum furnaces represent a significant capital expense. They are complex machines that require specialized infrastructure, operation, and maintenance, making them less accessible than simpler methods like torch or induction brazing.

Longer Cycle Times

The need for pump-down and slow, controlled heating and cooling means that vacuum brazing cycles are inherently longer than many alternative processes. While this is beneficial for part quality, it can be a bottleneck for simple, low-volume work where speed is a priority.

Material Limitations

The process is not suitable for all materials. Metals with high vapor pressures at brazing temperatures, such as zinc, lead, magnesium, or cadmium, can outgas. This phenomenon, known as "vaporization," contaminates the vacuum furnace and can interfere with the braze joint itself.

Making the Right Choice for Your Application

Selecting the right brazing process depends entirely on your project's technical requirements and economic constraints.

- If your primary focus is maximum joint strength and purity: Vacuum brazing is the definitive choice for critical applications in aerospace, medical, and semiconductor manufacturing where joint failure is unacceptable.

- If your primary focus is joining complex or delicate assemblies: The uniform heating and stress-free cooling of a vacuum furnace make it ideal for intricate geometries or parts prone to distortion.

- If your primary focus is high-volume efficiency with integrated heat treatment: Vacuum brazing provides unparalleled value by combining multiple manufacturing steps into a single, automated furnace cycle.

- If your primary focus is cost-effectiveness for simple joints: For non-critical applications, the cost and complexity of vacuum brazing are likely unnecessary, and simpler methods would be more appropriate.

Ultimately, vacuum brazing is a precision manufacturing process where controlling the environment is just as crucial as controlling the temperature.

Summary Table:

| Parameter | Key Function | Typical Range / Goal |

|---|---|---|

| Brazing Temperature | Melt filler metal for capillary flow | Above filler liquidus, below base material melting point |

| Dwell Time | Ensure complete filler flow and joint filling | Long enough for full flow, short enough to prevent base material damage |

| Vacuum Level | Remove oxygen, prevent oxidation, enable flux-free wetting | 10⁻³ to 10⁻⁶ Torr |

| Heating/Cooling Rates | Manage thermal stress, ensure uniformity, prevent distortion | Controlled and slow for complex parts |

Achieve flawless, high-strength brazed joints for your critical applications.

KINTEK specializes in providing advanced laboratory equipment and consumables for precision thermal processes like vacuum brazing. Our expertise helps laboratories in aerospace, medical, and semiconductor manufacturing achieve superior joint integrity, unmatched cleanliness, and efficient integrated heat treatment.

Contact us today to discuss how our solutions can optimize your brazing process and enhance your results.

Get in touch via our Contact Form

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What materials are used in a vacuum furnace? A Guide to Hot Zone Materials and Processed Metals

- How to vacuum out a furnace? A Step-by-Step Guide to Safe DIY Maintenance

- What is the leak rate for a vacuum furnace? Ensure Process Purity and Repeatability

- Why do you vacuum for heat treatment? Achieve Flawless, High-Performance Metal Components