To vacuum out your furnace, you must first shut off all power to the unit. After removing the access door and burner cover, use a shop vac with a long wand or upholstery attachment to thoroughly vacuum the furnace base, burners, and any other accessible areas where dust and debris have collected.

The core task is straightforward, but it's critical to understand its limitations. While vacuuming is a vital part of routine DIY maintenance for removing surface-level debris, it is not a substitute for the comprehensive safety checks and deep cleaning performed by a qualified HVAC professional.

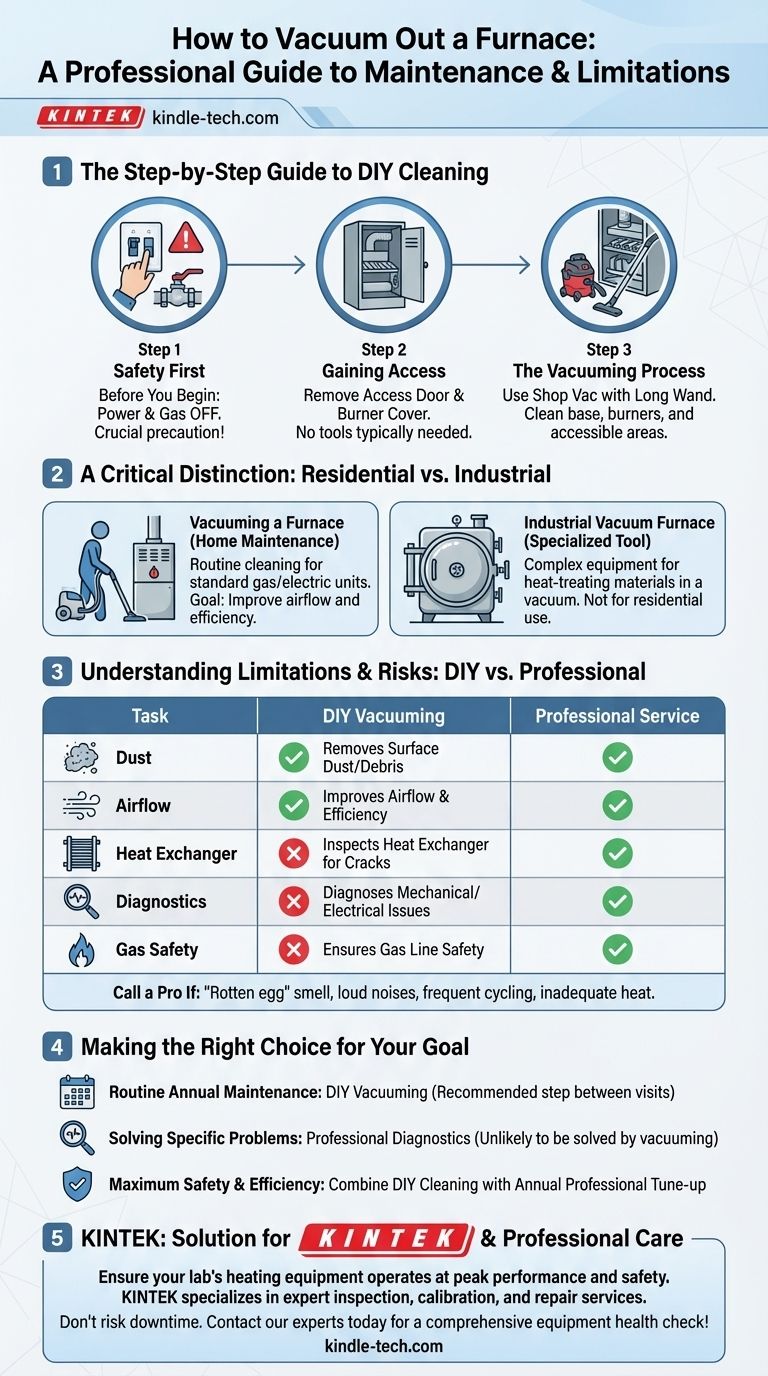

The Step-by-Step Guide to Cleaning Your Furnace

Properly cleaning your furnace is about more than just dust removal; it's a foundational step in maintaining the system's efficiency and safety. Follow these steps methodically.

Before You Begin: Safety First

This is the most critical step. Before opening any panels, you must completely cut power to the furnace. Locate the switch on or near the unit, which often looks like a standard light switch. For absolute certainty, switch off the corresponding breaker in your main electrical panel.

If you have a gas furnace, you should also shut off the gas supply line leading to the unit as a precaution.

Gaining Access to the Components

Your furnace has a main access door or panel covering the internal components. This panel can typically be lifted up and pulled away from the unit without tools.

Once inside, you may see a smaller burner cover. Loosen the screws holding it in place and set it aside carefully. This will expose the burners and the furnace base.

The Vacuuming Process

Using a shop vac is ideal, but a household vacuum with a long hose and narrow attachment will also work.

Start by vacuuming the base of the furnace, working your way from front to back. Use extension wands if necessary to reach the rear corners where dust and debris often accumulate.

Next, gently vacuum the burners themselves. Be careful not to bump or dislodge any wires or the pilot light assembly. The goal is to remove dust, not to scrub the components.

A Critical Distinction: What "Vacuuming a Furnace" Means

The term "vacuum furnace" can cause significant confusion. It is essential to distinguish between routine maintenance and a specific type of industrial equipment.

"Vacuuming a Furnace": Simple Home Maintenance

This refers to the cleaning process described above. It is a maintenance task for a standard residential gas or electric furnace, which operates by heating air and distributing it through your home under normal atmospheric pressure.

"Industrial Vacuum Furnace": A Specialized Tool

This is a completely different piece of equipment used in manufacturing and material science. It operates by creating a low-pressure vacuum inside a sealed chamber to heat-treat materials without exposing them to air, preventing oxidation and contamination. This process has no application in a residential setting.

Understanding the Limitations and Risks

DIY vacuuming is beneficial, but it's important to recognize what it can and cannot do.

What You Can Accomplish

Regularly vacuuming your furnace can help remove dust, soot, and small debris that can impede airflow, reduce efficiency, and potentially become a fire hazard. This simple action supports the overall health of your HVAC system.

What Vacuuming Alone Can't Fix

This task will not resolve underlying mechanical or electrical problems. Issues like a faulty ignitor, a sensor malfunction, a cracked heat exchanger, or gas supply problems require professional diagnostic tools and expertise.

When to Call a Professional

While DIY cleaning is good, it does not replace an annual professional inspection. You should call an HVAC technician immediately if you notice:

- A "rotten egg" smell (potential gas leak).

- Loud banging or screeching noises.

- The furnace cycles on and off too frequently.

- The unit fails to produce adequate heat.

A professional service includes cleaning hard-to-reach areas, inspecting the heat exchanger for dangerous cracks, checking gas pressure, and testing safety controls.

Making the Right Choice for Your Goal

Use this guide to determine the best course of action based on your objective.

- If your primary focus is routine annual maintenance: DIY vacuuming is an excellent and recommended step to perform between professional service visits.

- If your primary focus is solving a specific heating problem: Vacuuming is unlikely to be the solution, and you should schedule a diagnostic appointment with a qualified technician.

- If your primary focus is ensuring maximum safety and efficiency: Combine your own light cleaning with a scheduled professional inspection and tune-up every single year.

Ultimately, understanding your furnace and performing simple maintenance empowers you to keep your system running efficiently and safely.

Summary Table:

| Task | DIY Vacuuming | Professional Service |

|---|---|---|

| Removes Surface Dust/Debris | Yes | Yes |

| Improves Airflow & Efficiency | Yes | Yes |

| Inspects Heat Exchanger for Cracks | No | Yes |

| Diagnoses Mechanical/Electrical Issues | No | Yes |

| Ensures Gas Line Safety | No | Yes |

Ensure your lab's heating equipment operates at peak performance and safety. While DIY maintenance is helpful for surface cleaning, the complex systems in your laboratory require expert care. KINTEK specializes in lab equipment and consumables, serving laboratory needs with professional inspection, calibration, and repair services for furnaces and other critical equipment. Don't risk downtime or safety hazards—contact our experts today for a comprehensive equipment health check!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- Can iron evaporate? Discover the Extreme Science Behind Gaseous Metals

- What is the use of evaporator in laboratory? Gentle Solvent Removal for Sensitive Samples

- What is sintered glass used for? Achieve Pure Filtration & Gas Diffusion in Your Lab

- How do high-precision stirring and dispersion devices facilitate the solution intercalation for nano-bio-composites?

- How does sintering increase density? Master the Process for Superior Material Performance

- Why is a magnetic stirrer necessary during the preparation of graphene oxide? Ensure Safety and Uniform Oxidation

- What affects the conductivity of materials? Unlock the Science Behind Electrical Performance

- What are the different types of sintering process? Choose the Right Method for Your Material