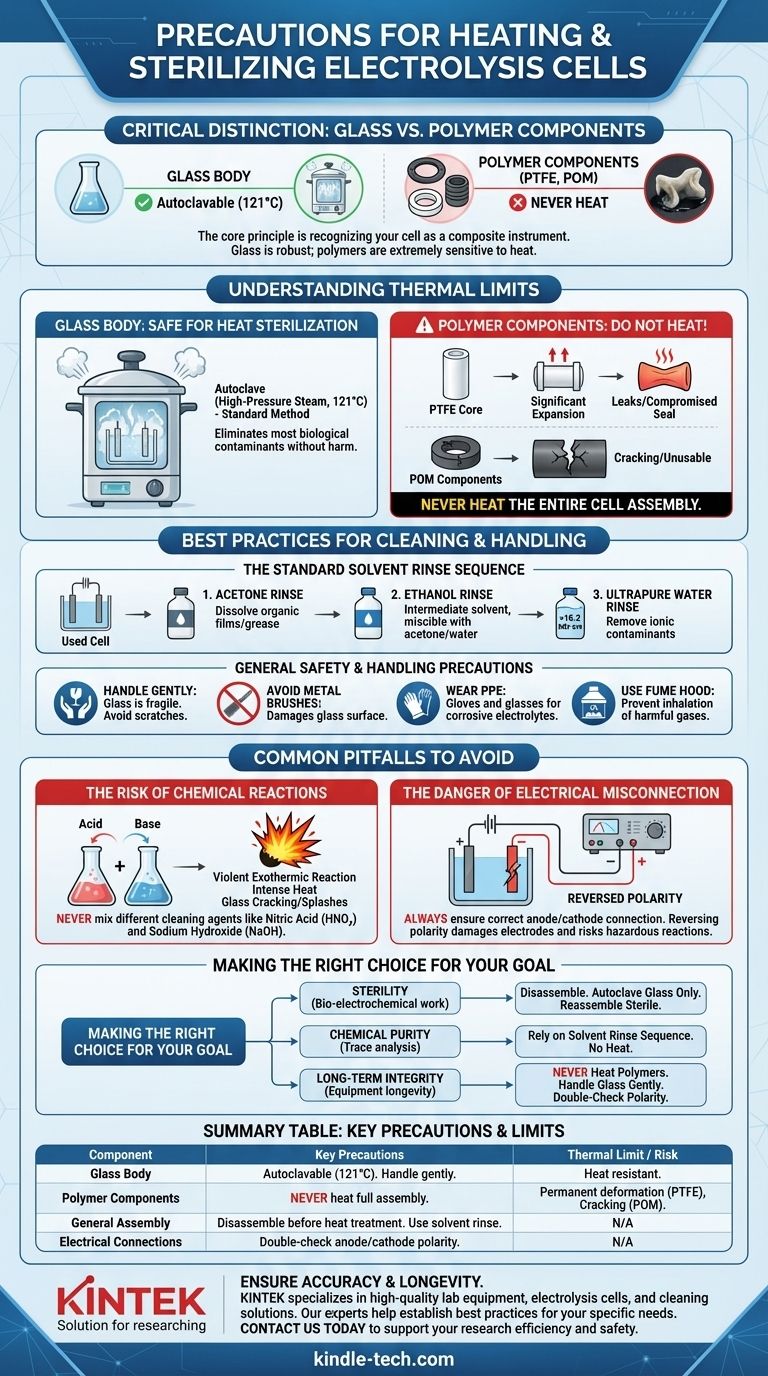

When sterilizing an electrolysis cell, you must treat its components differently based on their material composition. The glass body can typically be sterilized with high-pressure heat (autoclaved), but the complete cell assembly must never be heated. Doing so will cause irreversible damage to sensitive polymer components like PTFE and POM.

The core principle of safely handling an electrolysis cell is recognizing that it is a composite instrument. While the glass is robust against heat and chemicals, the polymer seals and cores are not, requiring a careful, component-specific approach to cleaning and sterilization.

The Critical Distinction: Glass vs. Polymer Components

Understanding the thermal limits of your cell's materials is the single most important factor in preventing its destruction during cleaning or sterilization.

Sterilizing the Glass Body

The glass portion of the electrolysis cell is highly durable and can be sterilized effectively.

The standard method is autoclaving, which involves using high-pressure saturated steam at 121°C. This is sufficient to eliminate most biological contaminants without harming the glass.

Why Polymer Components Cannot Be Heated

The plastic components of the cell assembly are extremely sensitive to heat.

The PTFE (Teflon) inner core will expand significantly when heated. Unlike metal or glass, it will not return to its original shape and dimensions upon cooling, leading to leaks and a compromised seal.

Other materials, such as POM (Polyoxymethylene), are prone to cracking under the stress of high temperatures, rendering the cell unusable. For this reason, you must never heat the entire cell assembly.

Best Practices for Cleaning and Handling

Beyond heat sterilization, proper chemical cleaning and careful handling are essential for maintaining the cell's integrity and ensuring accurate experimental results.

The Standard Solvent Rinse Sequence

For a previously used cell, a three-step chemical clean is the most effective way to remove residues.

- First, scrub the inner wall with acetone to dissolve any organic films or grease.

- Next, rinse thoroughly with ethanol, which is miscible with both acetone and water, acting as an intermediate solvent.

- Finally, perform multiple rinses with ultrapure water (resistivity >18.2 MΩ・cm) to remove all ionic contaminants.

General Safety and Handling Precautions

Safe operation extends beyond cleaning and is crucial for both user safety and equipment longevity.

Always handle the glass cell gently, as it is fragile and can be easily scratched or broken. Avoid using metal brushes for cleaning, as they will scratch the interior glass surface.

When working with corrosive electrolytes, you must wear protective gloves and glasses. All operations should be performed in a fume hood to prevent the inhalation of any harmful gases produced.

Common Pitfalls and Hazards to Avoid

Mistakes in handling or cleaning can lead to immediate equipment failure or create significant safety risks.

The Risk of Chemical Reactions

Never mix different types of cleaning agents, especially acids and bases like nitric acid (HNO₃) and sodium hydroxide (NaOH).

This combination can cause a violent exothermic reaction, generating intense heat that can crack the glass cell or cause dangerous splashes.

The Danger of Electrical Misconnection

Always ensure the anode and cathode are connected correctly to your potentiostat or power source.

Reversing the polarity can damage your electrodes, ruin your experiment, and in some cases, cause unintended and potentially hazardous electrochemical reactions within the cell.

Making the Right Choice for Your Goal

Your approach to cell preparation should be dictated by your specific experimental needs.

- If your primary focus is sterility for bio-electrochemical work: Disassemble the cell and autoclave the glass body only, then reassemble using sterile techniques.

- If your primary focus is chemical purity for trace analysis: Rely on the acetone, ethanol, and ultrapure water rinse sequence to remove contaminants without heat.

- If your primary focus is long-term equipment integrity: Make it a rule to never heat polymer components, always handle the glass gently, and double-check electrical polarity before every run.

Proper care and handling are not just about maintenance; they are fundamental to ensuring the accuracy of your results and the long life of your instrument.

Summary Table:

| Component | Key Precautions | Thermal Limit / Risk |

|---|---|---|

| Glass Body | Can be autoclaved (121°C). Handle gently to avoid scratches/breakage. | Heat resistant. |

| Polymer Components (PTFE/POM) | NEVER heat the full assembly. Heat causes permanent deformation (PTFE) or cracking (POM). | Extremely heat-sensitive. |

| General Assembly | Disassemble before any heat treatment. Use specific solvent rinse sequence for cleaning. | N/A |

| Electrical Connections | Always double-check anode/cathode polarity to prevent damage/hazards. | N/A |

Ensure the accuracy and longevity of your electrochemical experiments with the right equipment and expertise. KINTEK specializes in high-quality lab equipment and consumables, including electrolysis cells and cleaning solvents, to meet the precise needs of your laboratory. Our experts can help you select the right tools and establish best practices for maintenance and sterilization. Contact us today to discuss how we can support your research and ensure your lab's efficiency and safety.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Laboratory Test Sieves and Sieving Machines

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What is a lab autoclave? Your Guide to Sterilization with Pressurized Steam

- Can autoclave sterilize liquid? Master Safe and Effective Liquid Sterilization

- What are the sizes of autoclaves? A Guide to Choosing the Right Capacity for Your Lab

- Why is it important to autoclave the prepared reagents before using? Ensure Sterility and Reliable Results

- What temperature must be reached for sterilization in 10-12 minutes? Achieve Rapid, Reliable Sterility with Flash Autoclaving