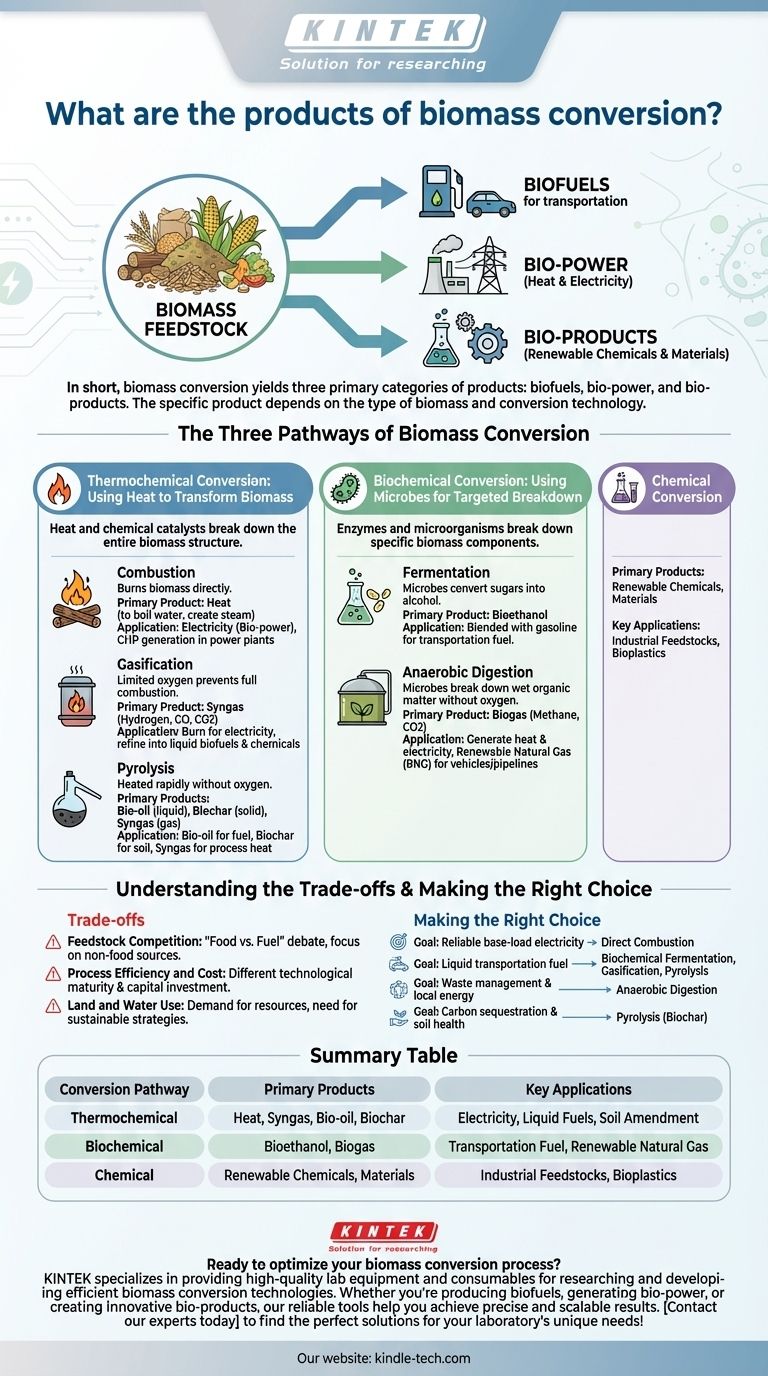

In short, biomass conversion yields three primary categories of products: biofuels for transportation, bio-power in the form of heat and electricity, and bio-products such as renewable chemicals and materials. The specific product created depends entirely on the type of biomass used and the conversion technology applied.

Biomass is not a single-source feedstock, and its conversion is not a single-track process. Understanding the final product requires first understanding the pathway taken, as each method is designed to optimize for a different type of energy or material output.

The Three Pathways of Biomass Conversion

Biomass can be converted into useful energy and products through three main technological routes: thermochemical, biochemical, and chemical conversion. Each pathway breaks down the raw organic matter differently, resulting in a distinct set of outputs.

Thermochemical Conversion: Using Heat to Transform Biomass

This is the most common and established set of methods. It uses heat and chemical catalysts to break down the entire biomass structure.

Combustion: This is the simplest method—biomass is burned directly in the presence of ample oxygen.

- Primary Product: Heat. This heat is most often used to boil water, create steam, and turn a turbine to generate electricity (bio-power).

- Application: It is widely used in industrial settings and power plants for combined heat and power (CHP) generation.

Gasification: Biomass is heated with a limited amount of oxygen, preventing full combustion.

- Primary Product: Syngas (synthesis gas), a mixture of hydrogen, carbon monoxide, and carbon dioxide.

- Application: Syngas is a versatile intermediate. It can be burned to generate electricity or further refined into liquid biofuels (like Fischer-Tropsch diesel) and valuable chemicals.

Pyrolysis: Biomass is heated rapidly in the complete absence of oxygen.

- Primary Products: This process yields three distinct products: bio-oil (a liquid), biochar (a solid charcoal-like substance), and syngas (a gas).

- Application: Bio-oil can be upgraded into transportation fuels. Biochar is a valuable soil amendment that improves fertility and sequesters carbon. The syngas is typically reused to power the pyrolysis process itself.

Biochemical Conversion: Using Microbes for Targeted Breakdown

This pathway uses enzymes and microorganisms to break down specific components of biomass, primarily the cellulose and hemicellulose mentioned in biofuel production.

Fermentation: This is a classic biological process where sugars are converted into alcohol by microbes like yeast.

- Primary Product: Bioethanol. This is the most common biofuel globally.

- Application: Bioethanol is blended with gasoline to increase octane and reduce emissions. Corn and sugarcane are the most common feedstocks.

Anaerobic Digestion: Microorganisms break down wet organic matter (like manure or food waste) in an oxygen-free environment.

- Primary Product: Biogas, which is primarily composed of methane and carbon dioxide.

- Application: The methane can be captured and burned to generate heat and electricity, or it can be purified into renewable natural gas (RNG) for use in vehicles or injected into natural gas pipelines.

Understanding the Trade-offs

While biomass conversion offers a sustainable alternative to fossil fuels, it is not without its challenges. Objectivity requires acknowledging the practical limitations of each method.

Feedstock Competition (The "Food vs. Fuel" Debate)

Using food crops like corn and sugarcane to produce ethanol raises ethical concerns about competing with the global food supply and potentially driving up food prices. This has led to a focus on second-generation biofuels from non-food sources like switchgrass, wood chips, and agricultural waste.

Process Efficiency and Cost

Each conversion pathway has different levels of technological maturity and cost. Direct combustion is relatively simple and inexpensive, while producing advanced liquid biofuels from syngas or pyrolysis oil requires significant capital investment and further refinement.

Land and Water Use

Cultivating dedicated energy crops for biomass can create significant demand for agricultural land and water resources. Sustainable biomass strategies must prioritize the use of waste materials and crops grown on marginal lands to avoid negative environmental impacts.

Making the Right Choice for Your Goal

The "best" biomass product is entirely dependent on the desired outcome. Your choice of conversion technology should be guided by your end goal.

- If your primary focus is generating reliable, base-load electricity: Direct combustion of woody biomass or waste materials is the most mature and economically viable pathway.

- If your primary focus is producing liquid fuel for transportation: Biochemical fermentation to create ethanol is the most established route, while gasification and pyrolysis offer future pathways to more advanced "drop-in" fuels.

- If your primary focus is waste management and local energy: Anaerobic digestion is an ideal solution for converting wet organic waste from farms, industries, and municipalities into on-site power and heat.

- If your primary focus is carbon sequestration and soil health: Pyrolysis is unique in its ability to produce biochar, a stable form of carbon that can be returned to the soil, creating a carbon-negative energy cycle.

Ultimately, viewing biomass conversion as a portfolio of solutions, rather than a single silver bullet, is the key to unlocking its full potential.

Summary Table:

| Conversion Pathway | Primary Products | Key Applications |

|---|---|---|

| Thermochemical | Heat, Syngas, Bio-oil, Biochar | Electricity, Liquid Fuels, Soil Amendment |

| Biochemical | Bioethanol, Biogas | Transportation Fuel, Renewable Natural Gas |

| Chemical | Renewable Chemicals, Materials | Industrial Feedstocks, Bioplastics |

Ready to optimize your biomass conversion process? KINTEK specializes in providing high-quality lab equipment and consumables for researching and developing efficient biomass conversion technologies. Whether you're producing biofuels, generating bio-power, or creating innovative bio-products, our reliable tools help you achieve precise and scalable results. Contact our experts today to find the perfect solutions for your laboratory's unique needs!

Visual Guide

Related Products

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Custom PTFE Teflon Parts Manufacturer for Reagent Wide Mouth Fine Mouth Sample High Temperature Bottles

- 5L Chilling Circulator Cooling Water Bath Circulator for Low Temperature Constant Temperature Reaction Bath

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What is the function of a laboratory shaker during batch adsorption experiments? Optimize Fly Ash Kinetic Research

- What role does high-speed stirring equipment play in fungal pre-cultures? Optimize Your Solid-State Fermentation

- What is the difference between a shaker and a vortex? Choose the Right Mixer for Your Lab Workflow

- How does a laboratory stirrer influence MOF product quality? Master Precision in Non-Solvothermal Synthesis

- What is the role of laboratory stirring equipment in nZVI preparation? Achieve Stable and Uniform Nano Slurries