At its core, alumina powder is a highly effective polishing abrasive due to its exceptional hardness and chemical stability, making it suitable for various materials. The most critical handling precautions involve preventing inhalation by ensuring proper ventilation and, just as importantly, avoiding cross-contamination between different particle sizes to achieve a flawless finish.

The success of any polishing task using alumina hinges on rigorous process control. A single misplaced coarse particle can undo all your work, making the prevention of cross-contamination just as critical as the material's abrasive properties.

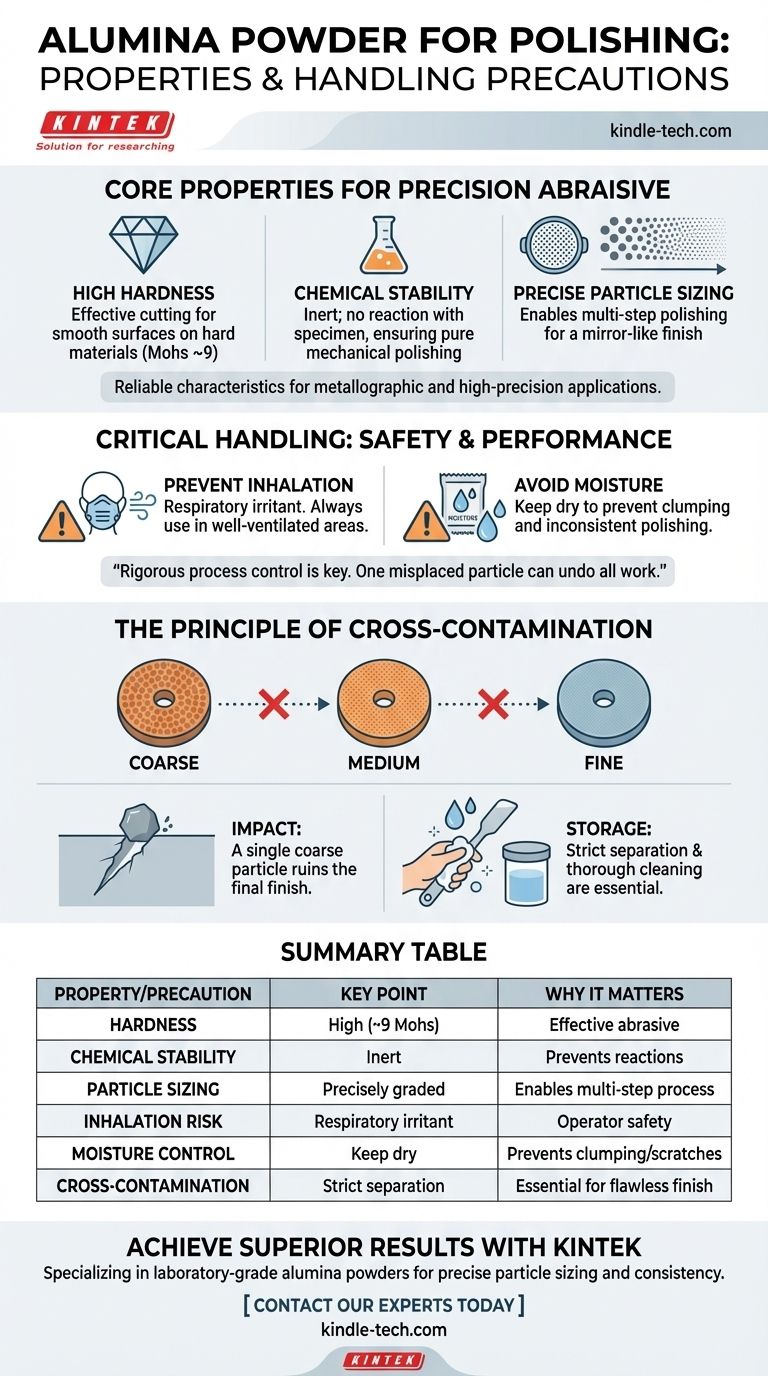

Core Properties of Alumina as an Abrasive

Alumina (aluminum oxide) is a preferred abrasive for metallographic and other high-precision polishing applications because of its reliable and predictable characteristics.

High Hardness

Alumina's significant hardness is its primary advantage. This property allows it to effectively cut and abrade a wide range of harder materials, creating a smooth, flat surface.

Chemical Stability

The powder is chemically inert, meaning it will not react with the surface of the specimen you are polishing. This ensures that the material removal process is purely mechanical, preventing unwanted etching or chemical alteration.

Precise Particle Sizing

Alumina powder is commercially available in a variety of precisely graded particle sizes. This allows for a multi-step polishing process, starting with a coarser grit to remove initial damage and progressing to finer grits for a mirror-like finish.

Critical Handling for Safety and Performance

Proper handling is not just about safety; it is fundamental to achieving the desired polishing outcome. Carelessness can compromise both the operator and the workpiece.

Preventing Inhalation

Alumina dust is a respiratory irritant. Always handle the powder in a well-ventilated area to avoid inhaling fine particles.

Avoiding Moisture

The powder must be kept dry. Moisture can cause the fine particles to agglomerate or clump, leading to inconsistent polishing and potential scratching.

Always check that packaging is sealed and intact. If you suspect moisture exposure, the powder should be dried thoroughly before use or replaced.

The Principle of Cross-Contamination

This is the single most common point of failure in a multi-stage polishing process. The goal is to move from larger scratches to progressively smaller ones, which is impossible if coarser particles are carried over.

The Impact of a Single Particle

Transferring even one larger abrasive particle onto a polishing cloth meant for a finer powder will introduce deep scratches. This will prevent you from achieving the desired high-quality surface finish.

Strict Separation is Essential

Store powders of different particle sizes in completely separate containers. Never swap the caps between containers or pour a larger particle size into a container designated for a smaller one.

Maintain Cleanliness Between Stages

When switching to a finer alumina powder, you must thoroughly clean your hands, the sample, and any tools with water. Use a separate, clean spatula dedicated to each particle size to prevent accidental transfer.

Applying This to Your Polishing Goal

Your specific approach to handling alumina powder should align with your primary objective for the task.

- If your primary focus is achieving the highest quality surface finish: Your priority must be the absolute prevention of cross-contamination by cleaning meticulously between each polishing stage.

- If your primary focus is operator safety and material longevity: Ensure you are always working in a well-ventilated space and storing the powders in dry, clearly labeled, and sealed containers.

Mastering the discipline of handling alumina powder is the key to unlocking its full potential for a perfect finish.

Summary Table:

| Property/Precaution | Key Point | Why It Matters |

|---|---|---|

| Hardness | High (Mohs scale ~9) | Effectively cuts and abrades hard materials for a smooth surface. |

| Chemical Stability | Inert | Prevents chemical reactions, ensuring pure mechanical polishing. |

| Particle Sizing | Precisely graded | Enables a multi-step process from coarse to mirror finish. |

| Inhalation Risk | Respiratory irritant | Requires handling in a well-ventilated area for operator safety. |

| Moisture Control | Must be kept dry | Prevents clumping and inconsistent polishing that can cause scratches. |

| Cross-Contamination | Strict separation needed | A single coarse particle can ruin the finish; meticulous cleaning is essential. |

Ready to achieve a flawless, mirror-like finish on your specimens?

The disciplined handling of high-quality alumina powder is critical to your success. At KINTEK, we specialize in providing laboratory-grade alumina powders and consumables that deliver the precise particle sizing and consistency your metallographic and precision polishing applications demand.

Our expertise ensures you have the right materials to prevent cross-contamination and achieve superior results. Let us help you optimize your polishing process for maximum efficiency and quality.

Contact our experts today to discuss your specific needs and discover how KINTEK's lab equipment and consumables can enhance your laboratory's capabilities.

Visual Guide

Related Products

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- Advanced Engineering Fine Ceramics Aluminum Nitride (AlN) Ceramic Sheet

People Also Ask

- What is the maximum temperature for alumina tube? Unlock Its Full Potential with High Purity

- What is the function of alumina setter plates for LATP? Protect Material Purity & Prevent Adhesion

- What functions do high-purity alumina support rods serve in sCO2 experiments? Ensure High-Temp Material Integrity

- What is the primary purpose of using alumina sintering plates? Ensure Purity for R1/3Zr2(PO4)3 Samples

- What are the process advantages of selecting an alumina plate for CuO nanofilm synthesis? Achieve Superior Purity