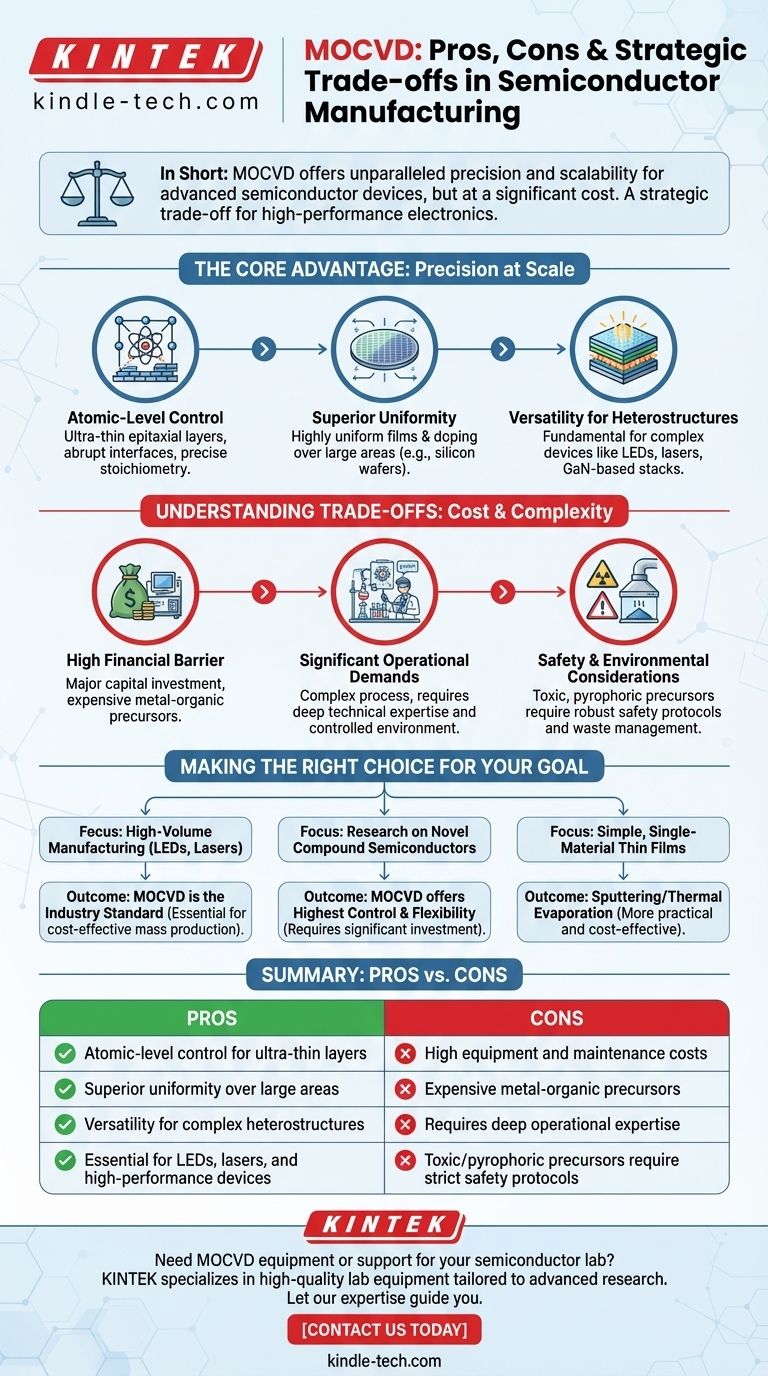

In short, MOCVD offers unparalleled precision and scalability for manufacturing advanced semiconductor devices, but at a significant cost. This technique, formally known as Metalorganic Chemical Vapor Deposition, allows for the growth of extremely pure, uniform crystalline layers. This control is critical for high-performance electronics, but it demands expensive equipment, costly materials, and deep operational expertise.

The core decision to use MOCVD is a strategic trade-off. You are choosing to accept high initial costs and operational complexity in exchange for unmatched control over material quality and the ability to scale production for complex devices like LEDs and lasers.

The Core Advantage: Precision at Scale

MOCVD is not merely a deposition technique; it is a foundational process for building the high-performance compound semiconductors that power modern technology. Its primary advantages lie in its ability to combine atomic-level control with the demands of large-scale manufacturing.

Atomic-Level Control of Film Growth

The process allows for the deposition of ultra-thin epitaxial layers, sometimes just a few atoms thick.

This enables the creation of abrupt interfaces between different material layers, which is crucial for the performance of advanced electronic and optoelectronic devices. Control over film stoichiometry, or the precise ratio of elements, is also far easier to manage compared to other methods.

Superior Doping and Composition Uniformity

A key strength of MOCVD is its ability to produce highly uniform films over large areas, such as an entire silicon wafer.

This includes precise control over doping, the intentional introduction of impurities to alter the material's electrical properties. This uniformity is essential for achieving high yields in mass production.

Versatility for Complex Heterostructures

MOCVD is exceptionally well-suited for growing heterostructures, which are structures composed of multiple, distinct material layers.

This capability is fundamental to manufacturing devices like high-brightness LEDs and semiconductor lasers, which rely on a sophisticated stack of carefully engineered layers, often using materials like Gallium Nitride (GaN).

Understanding the Trade-offs: Cost and Complexity

While powerful, MOCVD is not a universally applicable solution. Its adoption is limited by significant practical and financial challenges that must be carefully considered.

The High Financial Barrier to Entry

The most immediate disadvantage is cost. The equipment purchase, installation, and ongoing maintenance represent a major capital investment.

Furthermore, the metal-organic precursors used as the source materials are themselves very expensive, contributing significantly to the high operational costs.

Significant Operational Demands

MOCVD is often described as a "challenging art form" because it is a complex process to implement.

It requires a highly controlled lab environment and, more importantly, a team with deep technical expertise to dial in and maintain the process parameters for consistent, high-quality results.

Safety and Environmental Considerations

Many of the precursor gases and liquids used in MOCVD are toxic, pyrophoric (ignite spontaneously in air), or both.

This necessitates robust safety protocols, specialized handling equipment, and careful management of chemical waste, adding to both the complexity and environmental footprint of the operation.

Making the Right Choice for Your Goal

Selecting a deposition technology requires aligning its capabilities with your primary objective. MOCVD is a specialized tool designed for demanding applications.

- If your primary focus is high-volume manufacturing of complex optoelectronics (like LEDs and lasers): MOCVD is the undisputed industry standard, as its precision and scalability are essential for cost-effective mass production.

- If your primary focus is research on novel compound semiconductor devices: MOCVD offers the highest degree of control and flexibility, but you must be prepared for the significant investment in equipment and process expertise.

- If your primary focus is depositing simple, single-material thin films: The high overhead of MOCVD is unnecessary; more accessible techniques like sputtering or thermal evaporation are far more practical and cost-effective.

Ultimately, choosing MOCVD is an investment in manufacturing capability, enabling the production of advanced electronic devices that are otherwise unattainable.

Summary Table:

| Pros of MOCVD | Cons of MOCVD |

|---|---|

| Atomic-level control for ultra-thin layers | High equipment and maintenance costs |

| Superior uniformity over large areas | Expensive metal-organic precursors |

| Versatility for complex heterostructures | Requires deep operational expertise |

| Essential for LEDs, lasers, and high-performance devices | Toxic/pyrophoric precursors require strict safety protocols |

Need MOCVD equipment or support for your semiconductor lab? KINTEK specializes in providing high-quality lab equipment and consumables tailored to advanced research and production needs. Our expertise can help you navigate the complexities of MOCVD technology, ensuring you achieve optimal performance and efficiency. Contact us today to discuss how we can support your laboratory's goals!

Visual Guide

Related Products

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- What is the microwave plasma enhanced chemical vapor deposition process? Achieve Low-Temperature, High-Quality Coatings

- What are the limitations of diamonds? Beyond the Myth of Perfection

- What is the function of a Microwave PECVD system for Diamond Nanospikes? Precision 1-Step Nanostructure Synthesis

- What is the difference between MPCVD and HFCVD? Choose the Right CVD Method for Your Application

- How does Microwave Plasma Chemical Vapour Deposition (MPCVD) work? Your Guide to High-Purity Diamond Film Growth