The essential safety precautions for heat treatment involve a multi-layered approach combining proper Personal Protective Equipment (PPE), rigorous equipment checks before operation, and disciplined procedures for handling extremely hot materials and hazardous atmospheres. This system is designed to mitigate risks from severe burns, atmospheric hazards, and mechanical failures.

True safety in heat treatment is not a single action but a comprehensive system. It requires understanding the fundamental hazards—from extreme temperatures to invisible gases—and implementing rigorous, non-negotiable protocols for equipment, procedures, and personal protection.

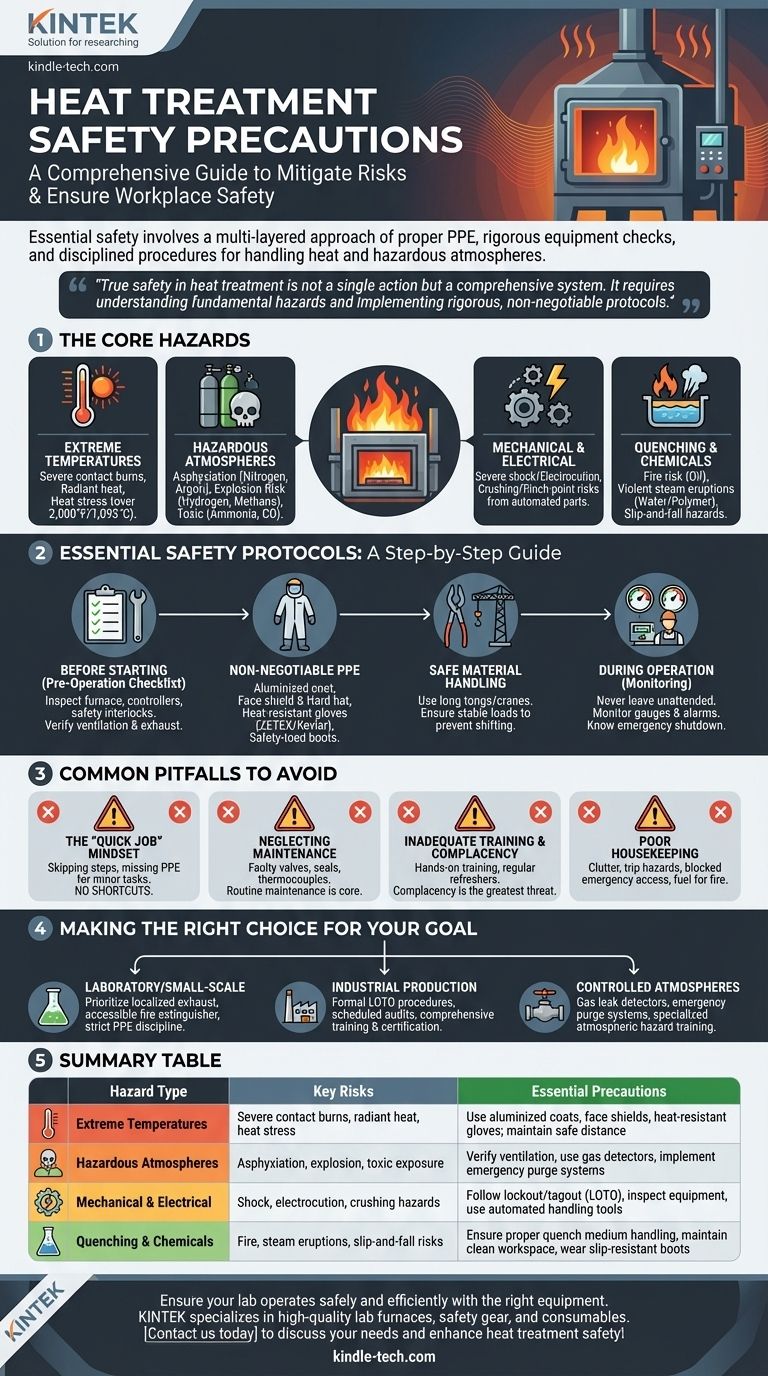

The Core Hazards of Heat Treatment

To implement effective safety measures, you must first understand the specific dangers inherent in the process. Heat treatment environments contain multiple, often simultaneous, hazards.

Extreme Temperatures

The most obvious danger is the intense heat, which can reach well over 2,000°F (1,093°C).

This creates risks of severe contact burns from touching parts, fixtures, or furnace interiors. It also produces powerful radiant heat, which can cause serious burns and heat stress even from a distance.

Hazardous Atmospheres

Many heat treatment processes require controlled atmospheres to achieve specific metallurgical properties, introducing chemical and atmospheric risks.

Gases like nitrogen and argon can cause asphyxiation by displacing oxygen. Flammable gases like hydrogen and methane present a significant explosion risk, while gases like ammonia or carbon monoxide are toxic.

Mechanical and Electrical Dangers

Furnaces are heavy industrial machinery with inherent mechanical and electrical risks.

High-voltage electrical systems pose a severe shock or electrocution hazard. Automated components like furnace doors, quench elevators, and material conveyors create crushing or pinch-point risks.

Quenching and Chemical Exposure

The quenching stage, used to rapidly cool parts, has its own unique set of hazards.

Using oil as a quench medium creates a fire risk if its flash point is exceeded or if hot parts are removed improperly. Water and polymer quenches can cause violent steam eruptions and create significant slip-and-fall hazards from splashes.

Essential Safety Protocols: A Step-by-Step Guide

A disciplined, procedural approach is the only way to reliably manage these hazards. Every step, from preparation to shutdown, must be governed by a clear safety protocol.

Before Starting: The Pre-Operation Checklist

Never begin work without a thorough inspection. Check that the furnace, controllers, and safety interlocks are in good working order.

Ensure all flammable materials are removed from the immediate area. Verify that ventilation and exhaust systems are functioning correctly, especially when using atmospheric gases.

Personal Protective Equipment (PPE) is Non-Negotiable

Standard work clothes are inadequate. Operators must be outfitted with specialized gear.

This includes an aluminized coat to reflect radiant heat, a hard hat with a face shield to protect from splashes and heat, and heat-resistant gloves (such as ZETEX or Kevlar) for handling hot materials. Safety-toed boots are mandatory to protect against falling objects.

Safe Material Handling and Loading

Properly handling parts prevents both injuries and equipment damage.

Use long tongs, cranes, or designated loading equipment to maintain a safe distance from the heat source. Ensure loads are stable and properly centered within the furnace to prevent them from shifting or falling during the cycle.

During Operation: Monitoring and Awareness

The operator's attention is a critical safety component.

Never leave a furnace unattended during operation. Constantly monitor temperature gauges, gas flow meters, and system indicators. Be familiar with all alarms and emergency shutdown procedures.

Common Pitfalls to Avoid

Even with established procedures, complacency and shortcuts can lead to disaster. Recognizing these common failure points is critical for maintaining a safe environment.

The "It's Just a Quick Job" Mindset

The most severe accidents often happen during brief, seemingly minor tasks where an operator decides to skip a safety step, such as not wearing a face shield or using the wrong tool. There are no shortcuts in heat treatment.

Neglecting Equipment Maintenance

A safety protocol is only as good as the equipment it governs. A faulty gas valve, a worn-out door seal, or an inaccurate thermocouple can lead to catastrophic failure. Routine preventative maintenance is a core safety function.

Inadequate Training and Complacency

Simply reading a manual is not enough. Operators need hands-on training on specific equipment and regular refreshers on emergency procedures. Complacency is the greatest threat to an experienced operator.

Poor Housekeeping

A cluttered, disorganized workspace is a direct safety threat. It creates trip hazards, obstructs access to emergency equipment like fire extinguishers and shutoffs, and can provide fuel in the event of a fire.

Making the Right Choice for Your Goal

Your specific process dictates which safety measures require the most emphasis.

- If your primary focus is on small-scale or laboratory heat treating: Prioritize localized exhaust ventilation, ensure a fire extinguisher is immediately accessible, and maintain strict discipline with PPE for every task.

- If your primary focus is on large-scale industrial production: Your system must be built around formal lockout/tagout (LOTO) procedures for maintenance, scheduled equipment audits, and comprehensive operator training and certification programs.

- If your primary focus is on processes with controlled atmospheres: Your top priority must be installing and testing gas leak detectors, engineering reliable emergency purge systems, and providing specialized training on atmospheric hazards and response.

Ultimately, safety in heat treatment is an active culture of discipline and risk awareness, not merely a passive list of rules.

Summary Table:

| Hazard Type | Key Risks | Essential Precautions |

|---|---|---|

| Extreme Temperatures | Severe contact burns, radiant heat, heat stress | Use aluminized coats, face shields, heat-resistant gloves; maintain safe distance |

| Hazardous Atmospheres | Asphyxiation, explosion, toxic exposure | Verify ventilation, use gas detectors, implement emergency purge systems |

| Mechanical & Electrical | Shock, electrocution, crushing hazards | Follow lockout/tagout (LOTO), inspect equipment, use automated handling tools |

| Quenching & Chemicals | Fire, steam eruptions, slip-and-fall risks | Ensure proper quench medium handling, maintain clean workspace, wear slip-resistant boots |

Ensure your lab operates safely and efficiently with the right equipment. KINTEK specializes in high-quality lab furnaces, safety gear, and consumables designed for reliable heat treatment processes. Our experts can help you select the ideal solutions to meet your safety protocols and performance goals. Contact us today to discuss your laboratory needs and enhance your heat treatment safety!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- What are the safety precautions for using a muffle furnace? Essential Tips for Safe Operation

- How do you keep a sample in a muffle furnace? A Guide to Safe and Accurate Placement

- What is the power rating of a muffle furnace? Choose the Right Voltage & Power for Your Lab

- What are the acceptance criteria for muffle furnace? Ensure Safety, Performance & Success

- What is the use of muffle furnace in food analysis? Master Ashing for Accurate Mineral Content