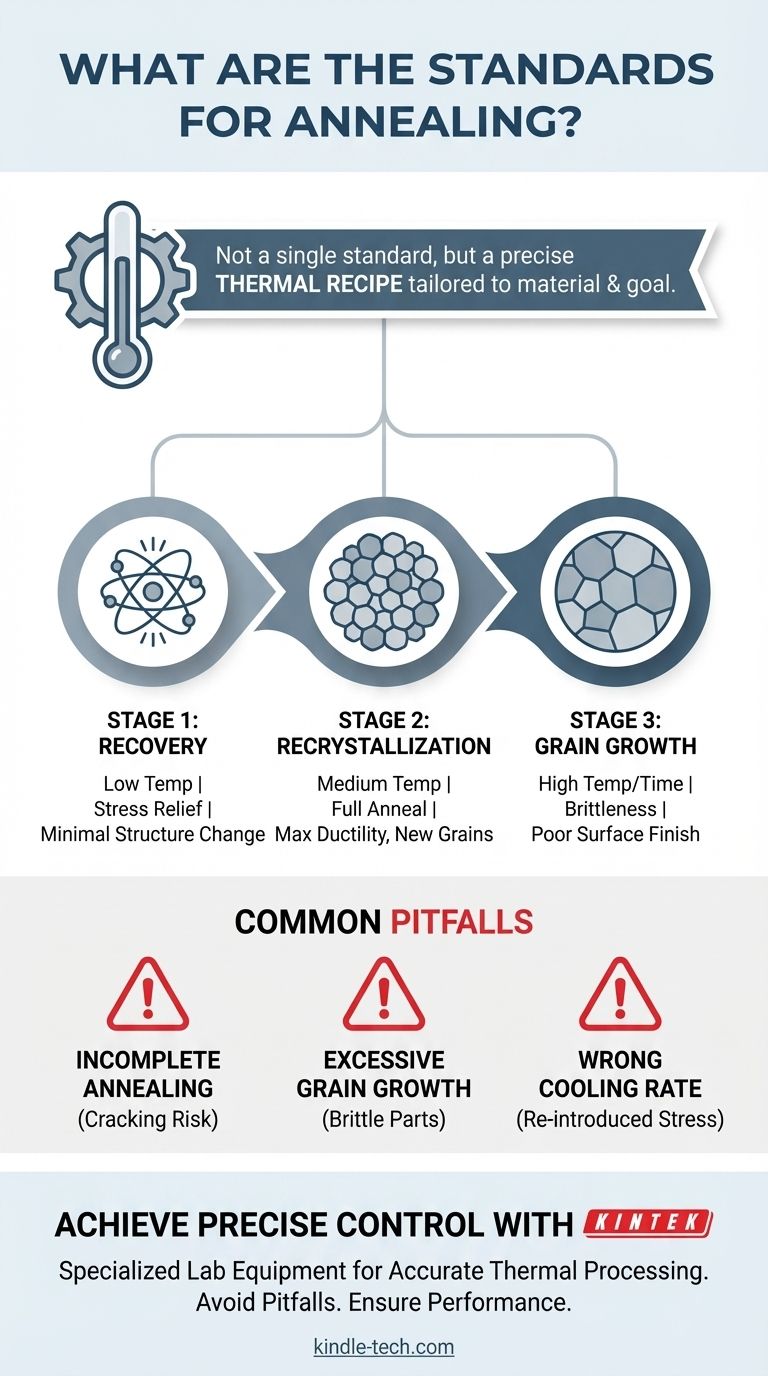

Unlike a simple bolt or screw, there is no single, universal standard for annealing. Instead, the "standard" is a precise thermal recipe—defined by temperature, time, and cooling rate—that is meticulously tailored to the specific material, its processing history, and the desired final properties.

The core principle to understand is that annealing isn't a single process but a category of heat treatments. The correct procedure is dictated by metallurgical principles and specific industry or material standards (e.g., from ASTM or AMS for aerospace alloys), not by one overarching document.

Why Annealing is Always Custom-Tailored

The primary purpose of annealing is to reverse the effects of processes like casting or cold working. These fabrication methods introduce internal stresses and distort the material's crystalline structure, making it hard and brittle.

The Goal: Relieving Internal Stress

The fundamental goal is to heat a material to a specific temperature to allow its internal structure to reset. This process relieves the built-up stresses, making the material softer, more ductile, and easier to work with.

The Material Defines the Parameters

Every metal and alloy has a unique annealing temperature range. The temperature that softens aluminum would be far too low to have any effect on steel. Using the wrong temperature can either fail to produce the desired effect or ruin the material entirely.

The History of the Material Matters

The amount of prior work done to a material dictates the required annealing process. A heavily cold-worked part has significantly more internal stress and structural deformation than a simple casting, requiring different time and temperature parameters to fully anneal.

The Three Foundational Stages of Annealing

While the specific parameters change, the underlying metallurgical process follows three distinct stages as the temperature increases. Understanding these stages is the key to controlling the outcome.

Stage 1: Recovery

At lower temperatures, the material enters the recovery stage. Internal stresses are relieved as atoms begin to move, but the fundamental grain structure of the metal does not significantly change. This is often used for simple stress-relief treatments where a large change in hardness is not desired.

Stage 2: Recrystallization

As the temperature rises further, the material begins to recrystallize. New, stress-free grains nucleate and grow, completely replacing the old, deformed grain structure. This is the core of a full anneal, resulting in a significant decrease in hardness and an increase in ductility.

Stage 3: Grain Growth

If the material is held at the annealing temperature for too long or if the temperature is too high, the newly formed grains will start to coarsen and merge. This grain growth is often undesirable, as an overly large grain structure can reduce the material's toughness and lead to a poor surface finish after forming.

Common Pitfalls in the Annealing Process

Deviating from the correct, tailored process introduces significant risks. The trade-offs are not between good and better, but often between success and failure.

Incomplete Annealing

Using a temperature that is too low or a hold time that is too short may only achieve partial recovery or recrystallization. The material will retain some of its internal stress and will not be as soft or ductile as expected, potentially leading to cracking in subsequent forming operations.

Excessive Grain Growth

This is the most common pitfall of improper annealing. By overheating the material or holding it at temperature for too long, the resulting coarse grain structure can make the part brittle and unsuitable for its intended application. This damage is often irreversible.

The Wrong Cooling Rate

The final step, cooling, is just as critical as heating. Cooling a part too quickly can re-introduce thermal stresses, negating the entire purpose of the process. For some alloys, a specific, controlled cooling rate is required to achieve the desired microstructure.

How to Define the Right Annealing Process

Instead of searching for a single standard, focus on your specific goal and material. This allows you to define the correct parameters.

- If your primary focus is relieving stress with minimal strength loss: Your process should target the Recovery stage, using lower temperatures and just enough time to reduce internal stress.

- If your primary focus is maximizing ductility for severe forming: You need a full anneal that ensures complete Recrystallization to produce a fine, uniform grain structure.

- If your primary focus is improving machinability: You may require a specialized annealing cycle designed to create a specific microstructure (like spheroidized carbides in steel) that is optimal for cutting.

Ultimately, a successful annealing process is a result of precise control, dictated by the unique needs of your material and your final objective.

Summary Table:

| Annealing Stage | Key Process | Resulting Material Property |

|---|---|---|

| Recovery | Low-temperature heating | Stress relief with minimal strength loss |

| Recrystallization | Heating to specific range | Maximum softness and ductility |

| Grain Growth | Overheating or excessive time | Brittleness and poor surface finish |

Achieve precise control over your annealing process with KINTEK.

Annealing is not a one-size-fits-all operation. Success depends on a deep understanding of your specific material and the precise thermal recipe required to achieve your desired properties—whether it's stress relief, maximum ductility, or improved machinability.

KINTEK specializes in advanced lab equipment and consumables for thermal processing. Our solutions provide the accuracy and reliability your laboratory needs to avoid common pitfalls like incomplete annealing or excessive grain growth, ensuring your materials perform as expected.

Let our experts help you define and execute the perfect annealing cycle for your application. Contact KINTEK today to discuss your specific laboratory requirements.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Multi-zone Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation