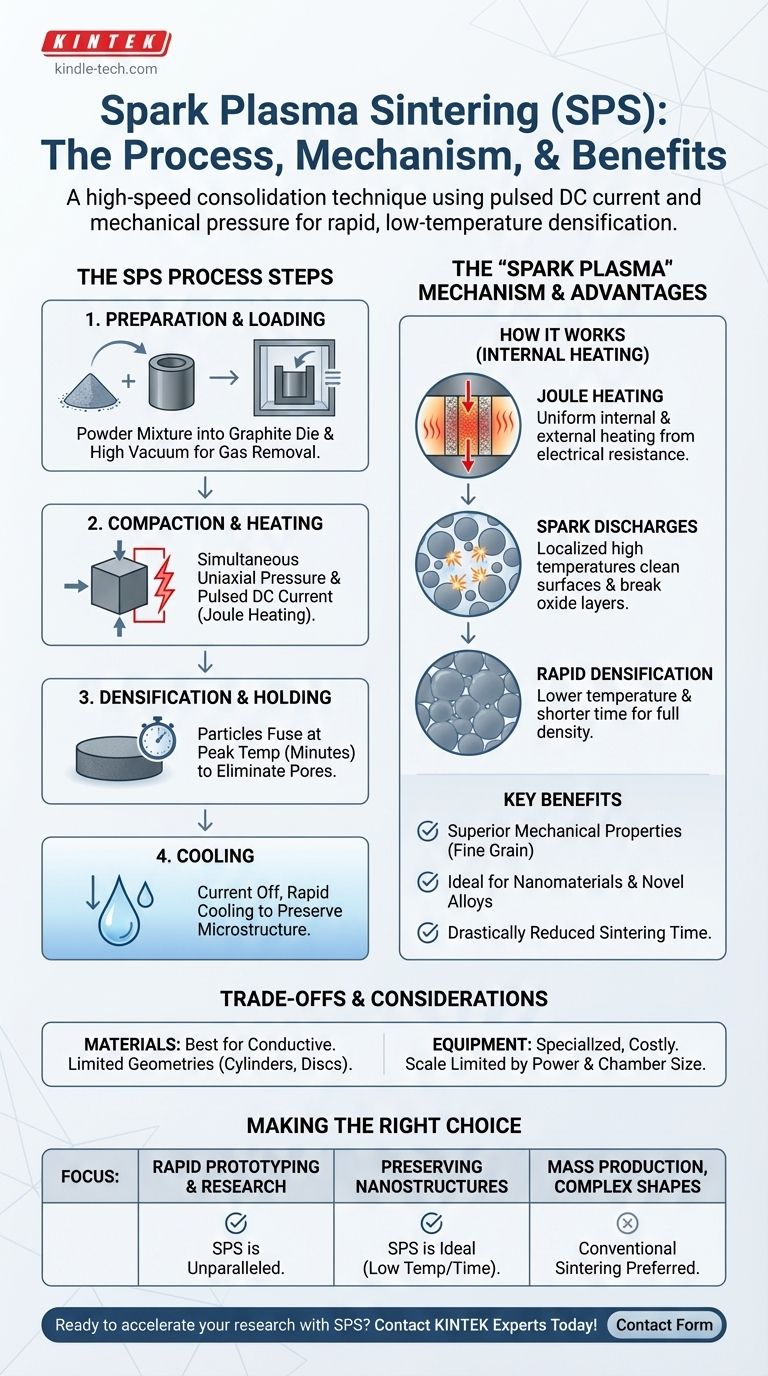

Spark Plasma Sintering (SPS) is a high-speed consolidation technique that typically involves four operational stages: loading and vacuum, simultaneous application of pressure and electric current for heating, a brief holding period for densification, and finally, rapid cooling. The unique aspect of SPS is its heating mechanism, where a pulsed DC current passes through the conductive die and the powder sample itself, leading to extremely fast and uniform heating.

The crucial difference in Spark Plasma Sintering is not just the steps, but how they are executed. By combining mechanical pressure with direct electrical current heating, SPS dramatically reduces the time and temperature required to fuse particles into a dense solid compared to conventional methods.

The SPS Process: A Step-by-Step Breakdown

While the core of the process happens inside the machine, understanding the full workflow from powder to final part is essential.

H3: Preparation of the "Green Body"

Before the SPS process can begin, the raw material must be prepared. This typically involves blending powdered metals or ceramics, often with additives, to create a homogenous mixture. This powder is then loaded into a conductive die, most commonly made of graphite.

H3: Stage 1: Loading and Gas Removal

The die containing the powder is placed into the SPS process chamber. The chamber is then sealed and evacuated to a high vacuum. This step is critical for removing air and other trapped gases that could cause oxidation or impurities in the final product.

H3: Stage 2: Compaction and Heating

This is the core event where SPS distinguishes itself. A uniaxial pressure is applied to the powder through punches, while a high-amperage, low-voltage pulsed DC current is passed directly through the die and the sample. This generates rapid, uniform heat throughout the material.

H3: Stage 3: Densification and Holding

The combination of pressure and high temperature causes the individual powder particles to deform and fuse together, a process known as densification. The material is held at the peak sintering temperature for a very short time—often just a few minutes—to allow pores to be eliminated and the part to reach its target density.

H3: Stage 4: Cooling

Once densification is complete, the electric current is switched off. The system then cools down rapidly, often with assistance. This rapid cooling helps preserve the fine-grained microstructure of the material, which is often desirable for achieving superior mechanical properties.

What "Spark Plasma" Actually Means

The name can be misleading. While true plasma is not typically generated, unique electrical phenomena occur between the powder particles that accelerate the sintering process.

H3: The Dominant Role of Joule Heating

The primary heating mechanism is Joule heating. As the electrical current passes through the conductive graphite die and the powder compact, their inherent electrical resistance causes them to heat up very quickly and uniformly. The die heats the sample externally, while the current passing through the powder heats it internally.

H3: The Impact of "Spark" Discharges

On a microscopic level, electrical discharges can occur in the gaps between adjacent powder particles. This momentary spark creates a localized, super-high temperature that serves two key purposes. It cleans the particle surfaces by vaporizing impurities and breaks down oxide layers, which prepares the surfaces for superior bonding.

H3: The Result: Rapid, Low-Temperature Densification

This dual heating mechanism allows the material to reach its sintering temperature in minutes rather than hours. The surface activation from spark discharges promotes the formation of "necks" between particles more effectively, enabling full densification at temperatures several hundred degrees lower than in a conventional furnace.

Understanding the Trade-offs and Considerations

While powerful, SPS is not a universal solution. Understanding its limitations is key to using it effectively.

H3: Material and Geometric Constraints

SPS is most effective for materials with at least some electrical conductivity. While insulating ceramics can be sintered because the graphite die gets hot, the process is less efficient. Furthermore, the use of a rigid die and uniaxial pressure generally limits the process to simple shapes like cylinders and discs.

H3: Equipment and Scale

SPS systems are specialized and more expensive than traditional furnaces. The size of the components that can be produced is also limited by the size of the processing chamber and the massive electrical power required for larger parts.

Making the Right Choice for Your Goal

Selecting a sintering method depends entirely on your project's specific needs for speed, material properties, and geometry.

- If your primary focus is rapid prototyping or research: SPS is an unparalleled tool for quickly producing dense samples of novel alloys or composites for testing.

- If your primary focus is preserving nanostructures: The short cycle time and lower temperatures of SPS are ideal for consolidating nanomaterials without causing significant grain growth.

- If your primary focus is mass production of complex shapes: Conventional sintering processes, such as metal injection molding, are often more scalable and cost-effective for high-volume, geometrically complex parts.

Ultimately, mastering Spark Plasma Sintering is about leveraging its incredible speed and efficiency for materials where a fine-grained, fully dense microstructure is the priority.

Summary Table:

| SPS Process Stage | Key Action | Primary Benefit |

|---|---|---|

| 1. Loading & Gas Removal | Powder is loaded into a graphite die; chamber is evacuated. | Removes gases to prevent oxidation and impurities. |

| 2. Compaction & Heating | Uniaxial pressure and pulsed DC current are applied simultaneously. | Rapid, uniform heating via Joule heating and spark discharges. |

| 3. Densification & Holding | Material is held at peak temperature for a short time (minutes). | Particles fuse, eliminating pores to achieve near-full density. |

| 4. Cooling | Current is switched off; system cools rapidly. | Preserves fine-grained microstructure for superior properties. |

Ready to leverage the speed and precision of Spark Plasma Sintering for your research or prototyping?

KINTEK specializes in advanced lab equipment, including sintering solutions, to help you achieve rapid densification and preserve delicate nanostructures. Our expertise supports researchers and engineers in developing materials with superior properties.

Contact our experts today to discuss how our solutions can accelerate your materials development goals.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What are the advantages of SPS? Achieve Superior Material Density and Performance

- What is the mechanism of SPS process? A Deep Dive into Rapid, Low-Temperature Sintering

- What is the SPS process of spark plasma sintering? A Guide to Rapid, Low-Temperature Densification

- What is the vapor phase material? Unlock Faster, Denser Sintering with SPS Technology

- Can aluminum be sintered? Overcome the Oxide Barrier for Complex, Lightweight Parts