While there is no single temperature limit for all platinum disk electrodes, the practical constraint is almost always determined by the insulating material used for the electrode body, not the platinum itself. Standard polymer-based electrodes can begin to deform or fail at temperatures as low as 80 °C, while specialized high-temperature designs can operate at several hundred degrees Celsius.

The true temperature limitation of your platinum disk electrode is dictated by the least heat-resistant component in its assembly—typically the PEEK, Teflon, or epoxy resin body that encases the platinum disk.

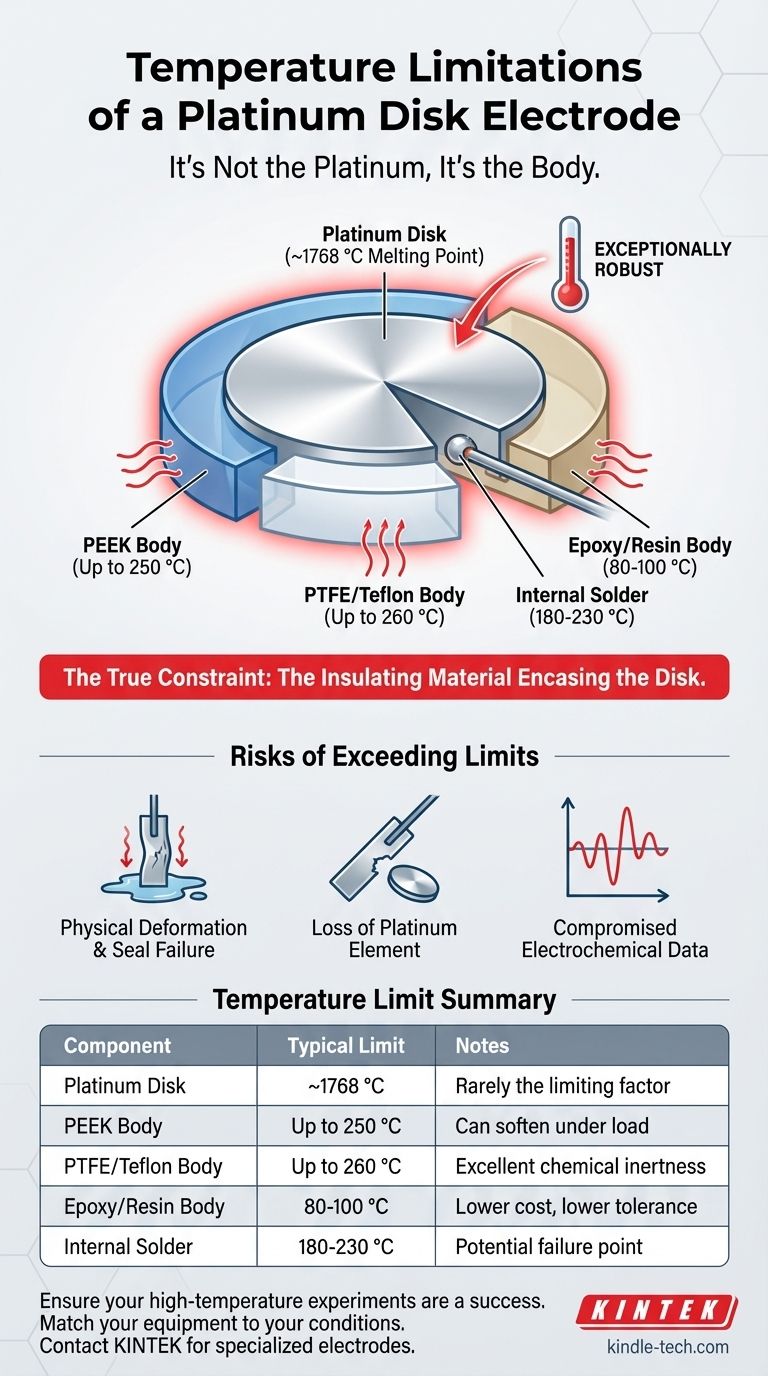

Why Electrode Construction Defines the Temperature Limit

To understand the operational limits, you must look at the electrode as a complete system. The platinum metal itself is exceptionally robust, but it's only one part of the assembly.

The Platinum Disk Itself

The melting point of pure platinum is approximately 1768 °C (3215 °F). For nearly all electrochemical applications, the metal disk is not the point of failure. Its stability is a primary reason it's chosen as an electrode material.

The Insulating Body (The Real Constraint)

The insulating sheath holds the platinum disk in place and ensures a well-defined active area. This component is the most common source of temperature-related failure.

Common materials include:

- PEEK (Polyether Ether Ketone): A high-performance polymer often used for its chemical resistance. Its continuous service temperature is typically up to 250 °C (482 °F), but it can soften at lower temperatures under load.

- PTFE (Polytetrafluoroethylene / Teflon): Known for its excellent chemical inertness. It can typically handle continuous service up to 260 °C (500 °F).

- Epoxy or Other Resins: Often used in lower-cost or disposable electrodes. These materials have a much lower temperature tolerance, sometimes failing above 80-100 °C (176-212 °F).

The Internal Electrical Connection

Inside the electrode body, a wire is connected to the back of the platinum disk, often using solder. Standard solder has a melting point far below that of platinum, typically in the range of 180-230 °C (356-446 °F).

Understanding the Risks of Exceeding the Limit

Pushing an electrode beyond its specified temperature range is not a matter of poor performance; it leads to irreversible damage and invalid experimental data.

Physical Deformation and Seal Failure

This is the most common failure mode. As the polymer body softens, the hermetic seal between the platinum disk and the insulator breaks. This allows the electrolyte to creep into the gap, destroying the defined electrode area and creating a path for massive, unstable background currents.

Loss of the Platinum Element

In a severe failure, the softened body material can no longer hold the metal disk in place, causing it to become loose or fall out entirely. The electrode is permanently destroyed.

Compromised Electrochemical Data

Even before catastrophic failure, minor deformation can alter the electrode's geometry. This changes the diffusion profile at the electrode surface, making your results non-reproducible and unreliable. High temperatures also accelerate side reactions and corrosion, further compromising data integrity.

Making the Right Choice for Your Goal

Always treat the manufacturer's specification sheet as the definitive source for your electrode's temperature limits. If this information is unavailable, exercise extreme caution when heating the system.

- If your primary focus is on standard aqueous electrochemistry (below 60 °C): A standard electrode with a PEEK, Teflon, or even an epoxy body is perfectly suitable and safe.

- If your primary focus is on high-temperature applications (above 80 °C): You must verify that your electrode is specifically designed for this purpose, likely one constructed with a PEEK or PTFE body, or a specialized glass or ceramic assembly for very high temperatures.

Ultimately, ensuring the integrity of your experiment requires matching your equipment's physical limitations to your desired chemical conditions.

Summary Table:

| Component | Typical Temperature Limit | Notes |

|---|---|---|

| Platinum Disk | ~1768 °C | Melting point; rarely the limiting factor. |

| PEEK Body | Up to 250 °C | High-performance polymer; can soften under load. |

| PTFE/Teflon Body | Up to 260 °C | Excellent chemical inertness. |

| Epoxy/Resin Body | 80-100 °C | Common in lower-cost electrodes; lower tolerance. |

| Internal Solder | 180-230 °C | Connection point; a potential failure point. |

Ensure your high-temperature experiments are a success. The integrity of your data depends on using the right equipment. KINTEK specializes in high-quality lab equipment and consumables, including electrodes designed for demanding thermal conditions. Don't risk experiment failure—contact our experts today to find the perfect electrode for your specific application and temperature range.

Visual Guide

Related Products

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Metal Disc Electrode Electrochemical Electrode

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Gold Disc Electrode

- Platinum Auxiliary Electrode for Laboratory Use

People Also Ask

- What is a common application for the platinum wire/rod electrode? The Essential Guide to Counter Electrodes

- What is the RRDE in electrochemistry? Unlock Detailed Reaction Pathways with Dual-Electrode Analysis

- What are the performance characteristics of platinum wire/rod electrodes? Unmatched Stability for Your Lab

- What is the application of RRDE? Unlock Quantitative Catalyst and Reaction Insights

- What is the difference between ring disk electrode and rotating disk electrode? Unlock Deeper Electrochemical Insights