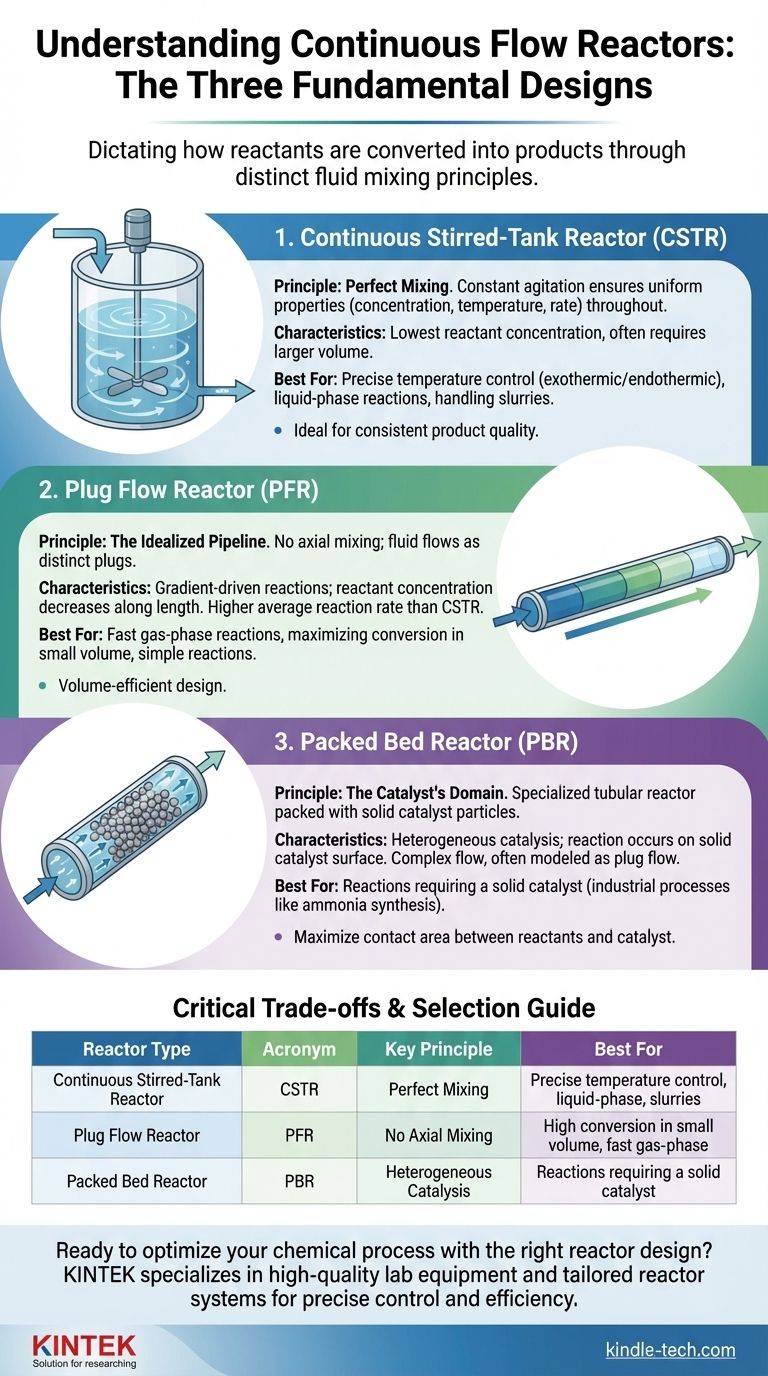

At the core of continuous chemical production are three fundamental reactor designs that dictate how reactants are converted into products. The three primary types of continuous flow reactors are the Continuous Stirred-Tank Reactor (CSTR), the Plug Flow Reactor (PFR), and the Packed Bed Reactor (PBR). Each operates on a distinct principle of fluid mixing and contact, making them suitable for very different chemical processes.

The choice between a CSTR, PFR, or PBR is not about which is universally "best," but about strategically matching the reactor's unique flow and mixing characteristics to the specific kinetics, heat demands, and phase requirements of your chemical reaction.

The Continuous Stirred-Tank Reactor (CSTR): The Principle of Perfect Mixing

A CSTR, as the name implies, is a tank fitted with an agitator (impeller) designed to create a state of "perfect mixing."

How It Works: Constant Agitation

Reactants are continuously fed into the tank, and the impeller ensures that the incoming material is immediately and thoroughly dispersed. This intense mixing means the properties of the fluid—concentration, temperature, and reaction rate—are uniform throughout the entire reactor volume.

Key Characteristic: Uniformity and Low Reactant Concentration

Because the contents are perfectly mixed, the concentration of reactants inside the CSTR is always at its lowest point, which is identical to the concentration of the product stream leaving the reactor. This results in the lowest possible reaction rate for a given conversion level, often requiring a large reactor volume.

When to Use a CSTR

CSTRs are ideal for liquid-phase reactions that require precise temperature control, especially highly exothermic or endothermic reactions. The large, mixed volume acts as a thermal buffer, preventing dangerous hot spots or cold spots. They are also favored when a consistent product quality is paramount.

The Plug Flow Reactor (PFR): The Idealized Pipeline

A PFR, often called a Tubular Reactor, is conceptually the opposite of a CSTR. It is typically a long pipe or tube through which the reaction mixture flows.

How It Works: No Axial Mixing

The core assumption of an ideal PFR is that fluid flows as a series of distinct "plugs," with no mixing in the direction of flow (axial mixing). Within each plug, however, mixing is assumed to be perfect in the radial direction (from the center to the wall).

Key Characteristic: Gradient-Driven Reactions

As a plug of fluid travels down the reactor, reactants are consumed, creating a continuous gradient. Reactant concentration is highest at the inlet and gradually decreases toward the outlet. This means the reaction rate starts high and slows down along the reactor's length, leading to a much higher average reaction rate than in a CSTR.

When to Use a PFR

PFRs are generally more volume-efficient than CSTRs. They are the preferred choice for fast, simple reactions, particularly in the gas phase. When the goal is to achieve the highest possible conversion in the smallest possible volume, a PFR is often the superior design.

The Packed Bed Reactor (PBR): The Catalyst's Domain

A Packed Bed Reactor is a specialized type of tubular reactor that is filled, or "packed," with solid particles.

How It Works: Flow Through a Stationary Phase

In a PBR, the reactants flow through the voids between stationary catalyst particles. The flow pattern is complex but is often modeled as plug flow. The reaction occurs on the surface of the catalyst, making this the workhorse for heterogeneous catalysis.

Key Characteristic: Heterogeneous Catalysis

The defining feature of a PBR is its ability to facilitate reactions between a fluid (gas or liquid) and a solid catalyst. This design maximizes the contact area between the reactants and the catalyst surface, which is essential for many large-scale industrial processes like ammonia synthesis or petroleum refining.

When to Use a PBR

A PBR is the default choice whenever a solid catalyst is required for a reaction to proceed at a practical rate. It is used extensively across the chemical, petrochemical, and pharmaceutical industries for a vast array of catalytic processes.

Understanding the Critical Trade-offs

Choosing a reactor involves balancing competing factors. No single design is optimal for every situation.

Conversion Efficiency: PFR/PBR vs. CSTR

For most common reaction kinetics (orders greater than zero), a PFR or PBR will achieve a higher degree of conversion than a CSTR of the same volume. This is because the average reactant concentration, and thus the average reaction rate, is higher in the PFR.

Temperature Control: The CSTR Advantage

The CSTR's perfect mixing makes it far superior for temperature control. Highly exothermic reactions that could create dangerous hot spots in a PFR or PBR can be managed safely in a CSTR. This control can also improve selectivity by preventing side reactions that occur at high temperatures.

Cost and Complexity

PFRs can be as simple as a long coil of pipe, making them potentially cheaper and easier to construct. CSTRs require a vessel, an agitation system (motor, gearbox, shaft, impeller), and complex seals, which increases capital and maintenance costs. PBRs add the complexity of catalyst loading, pressure drop management, and potential catalyst deactivation.

Handling Solids

CSTRs can be designed to handle slurries or precipitating solids more effectively than PFRs or PBRs, where solids can cause blockages. A PBR is, by definition, already filled with solids, and introducing more can be a significant engineering challenge.

Selecting the Right Reactor for Your Process

Your choice should be dictated by the specific demands of your chemical system and your primary operational goal.

- If your primary focus is maximizing conversion in the smallest volume: A PFR is often the most efficient choice for simple, non-catalytic reactions.

- If your primary focus is precise temperature control for a highly exothermic reaction: A CSTR's uniform temperature provides a significant safety and selectivity advantage.

- If your primary focus is a reaction requiring a solid catalyst: A PBR is the industry standard, designed specifically for this purpose.

- If you are working with slow liquid-phase reactions or need to handle slurries: A CSTR is typically the most robust and practical solution.

By understanding these fundamental differences, you can engineer a process that is not just functional, but truly optimized for performance, safety, and efficiency.

Summary Table:

| Reactor Type | Acronym | Key Principle | Best For |

|---|---|---|---|

| Continuous Stirred-Tank Reactor | CSTR | Perfect Mixing | Precise temperature control, liquid-phase reactions, handling slurries |

| Plug Flow Reactor | PFR | No Axial Mixing | High conversion in small volume, fast gas-phase reactions |

| Packed Bed Reactor | PBR | Heterogeneous Catalysis | Reactions requiring a solid catalyst |

Ready to optimize your chemical process with the right reactor design? The experts at KINTEK are here to help. We specialize in providing high-quality lab equipment and consumables, including reactor systems tailored for your specific application—whether you need precise temperature control, high conversion efficiency, or robust catalytic performance.

Contact us today to discuss your laboratory needs and discover how our solutions can enhance your research and development efficiency.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electrolytic Electrochemical Cell Gas Diffusion Liquid Flow Reaction Cell

People Also Ask

- How is high pressure generated in an autoclave? Unlock the Science of Sterilization & Synthesis

- What is a high pressure autoclave? A Complete Guide to High-Temp, High-Pressure Reactors

- What is a high pressure high temperature autoclave reactor? Unlock Extreme Chemical Synthesis

- How high pressure is created in a lab? Master Safe and Precise Pressure Generation

- What is the pressure in a batch reactor? A Guide to Dynamic Control and Safety